Deep silicon etching method

A technology of deep silicon etching and etching, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of poor roughness of the etching bottom, reduce the quality of deep silicon etching, and reduce the selection ratio of etching To achieve the effect of inhibiting the formation of micro-mask and even silicon grass, improving the unevenness of the bottom and improving the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the deep silicon etching method provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

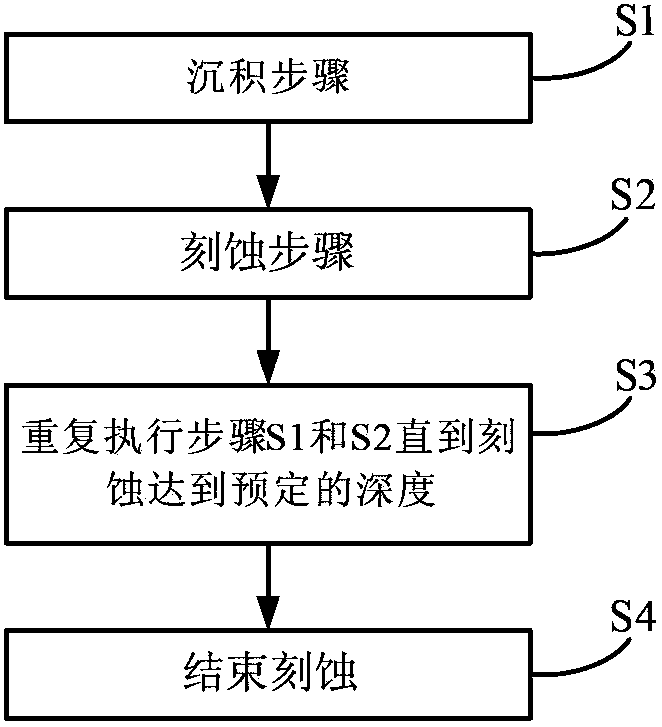

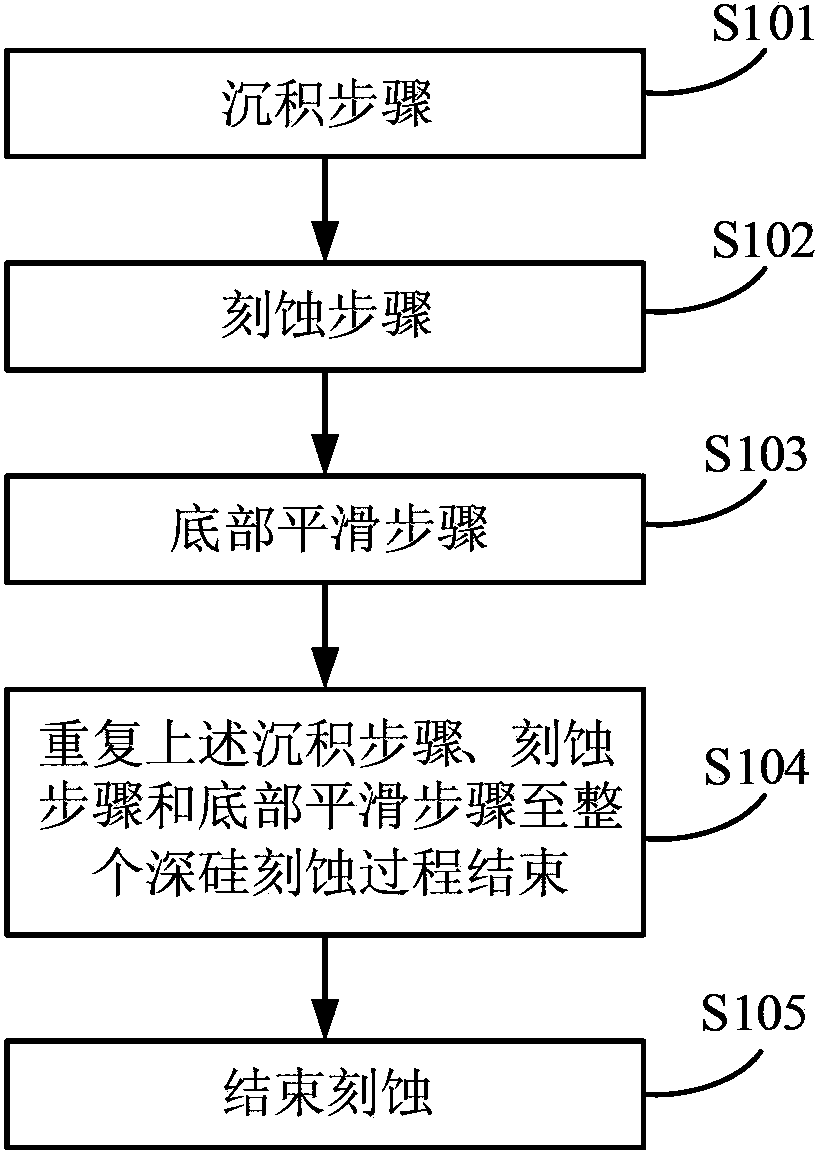

[0033] An embodiment of the present invention provides a deep silicon etching method, the method comprising: a deposition step, forming a protective layer to protect the etched sidewall; an etching step, etching the etched bottom and the etched sidewall; The deposition step and the etching step are repeated until the entire deep silicon etching process ends. In the deep silicon etching method, a bottom smoothing step is also included, the bottom smoothing step is: using a fluorine-containing gas to perform plasma treatment to remove the polymer produced at the bottom of the etching due to deposition; and, the bottom smoothing step adopts The process pressure is less than the process pressure used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com