Preparation method of ultrathin quartz glass plate

A quartz glass sheet and ultra-thin technology, which is applied in the field of preparation of ultra-thin quartz glass sheets, can solve the problems of fragmentation thickness and unevenness of quartz glass sheets, and achieve the effect of overcoming fragmentation and uneven thickness and avoiding fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention proposes a method for preparing an ultra-thin quartz glass sheet, which combines precision mechanical polishing and acid etching to prepare an ultra-thin quartz glass sheet; the thickness of the ultra-thin quartz glass sheet is ≤100 μm, and the thickness uniformity is -2μm~2μm, surface roughness Ra≤2nm.

[0027] Grinding and polishing is a surface processing process to obtain glass of required size and surface quality. Precision mechanical grinding and polishing will be more finely controlled than mechanical grinding and polishing. For ultra-thin sheets, precision mechanical polishing is to obtain good thickness uniformity and surface roughness, and hydrofluoric acid etching is to reduce the thickness to less than 100 μm; neither method alone can achieve the thickness ≦100μm, thickness uniformity of -2μm~2μm, and ultra-thin sheet processing with surface roughness≦2nm.

[0028] Before the quartz glass sheet of the present invention is ground, the ...

Embodiment 1

[0053] The present invention proposes a kind of preparation method of ultra-thin quartz glass sheet, comprises the following steps:

[0054] 1) Rough processing of quartz glass sheet: before grinding, the quartz glass sheet is ground or roughly ground, and its thickness is controlled to be 0.4mm;

[0055] 2) Precision mechanical grinding and polishing: use nodular cast iron as the grinding medium, and Al2O3 particles with a particle size of 10 μm are used as the abrasive for double-sided grinding, and the thickness of the removed quartz glass sheet is 80-170 μm; polyurethane is used as the polishing medium, and the particle size is 50-100nm. SiO2 particles are used as polishing powder for double-sided polishing, and the thickness of the removed quartz glass sheet is 20 to 30 μm; through this step, the quartz glass sheet is processed to a thickness of 0.2 to 0.3 mm, with a thickness uniformity of -5 μm to 5 μm, and a rough surface The first quartz glass polished piece with Ra≤1...

Embodiment 2-6

[0061] Step is with embodiment 1.

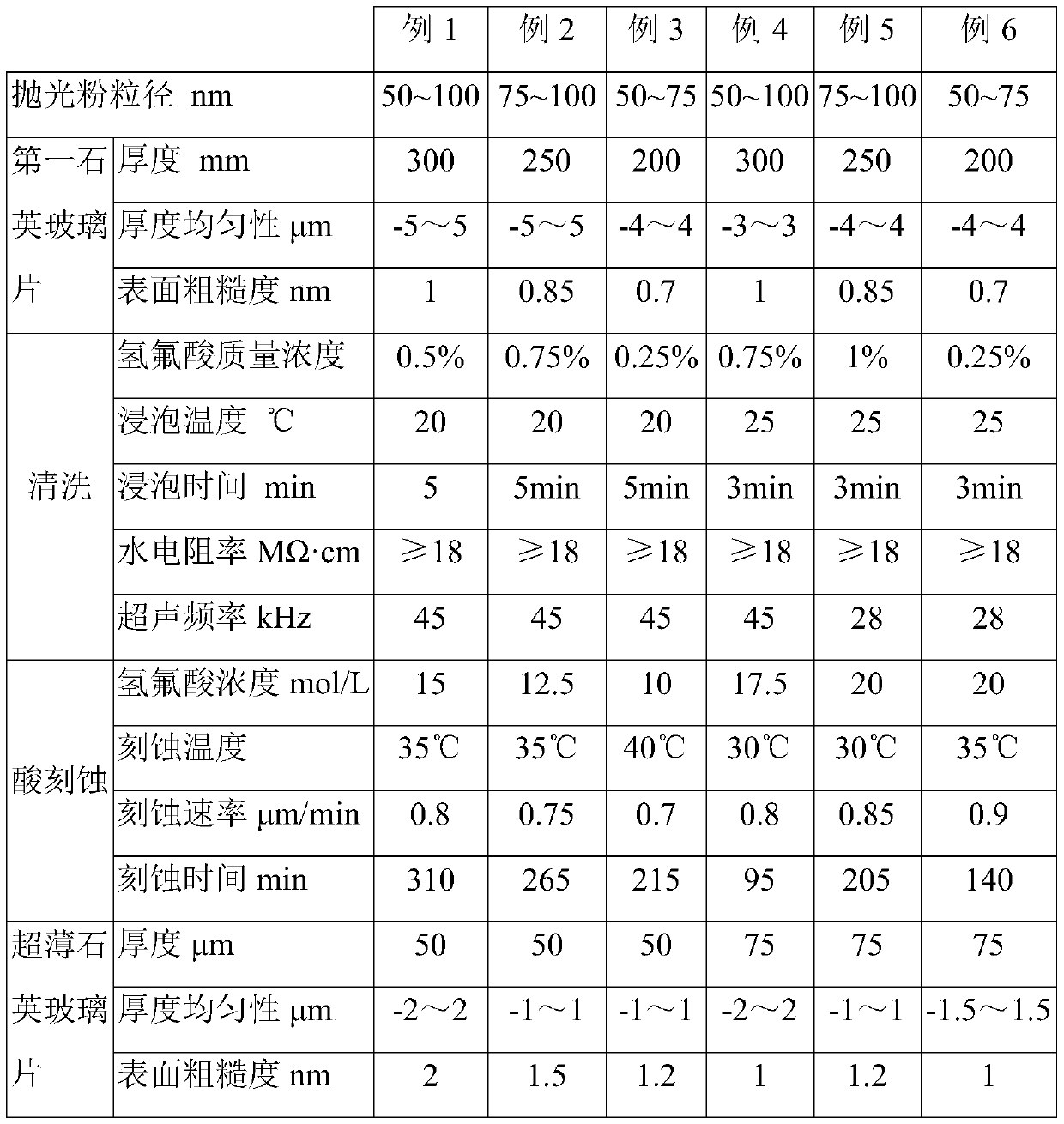

[0062] The process parameters of each embodiment were adjusted according to the data in Table 1 below, and the dimensions of the prepared ultra-thin quartz glass sheets are shown in Table 1.

[0063] Table 1 Process parameters and product performance of Examples 1-6

[0064]

[0065] As can be seen from the process parameters of Examples 1 to 6 shown in the above Table 1 and the performance data of the prepared products, the technical solution of the present invention uses a combination of precision mechanical polishing and hydrofluoric acid etching to process quartz glass Through the matching and coordination of process parameters in each process, the fragmentation of quartz glass flakes during the preparation process is avoided, and the thickness uniformity and surface roughness of ultra-thin quartz glass flakes are also improved. The prepared ultra-thin quartz glass sheet has a thickness of ≤100 μm, a thickness uniformity of -2 μm to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com