Impeller of centrifugal pump

A centrifugal pump impeller and blade technology, which is applied in the field of centrifugal pumps, can solve problems such as scrapped impellers, blockage of flow passages, and affecting the pass rate of impellers, and achieve reliable and more stable performance, smoothness and roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

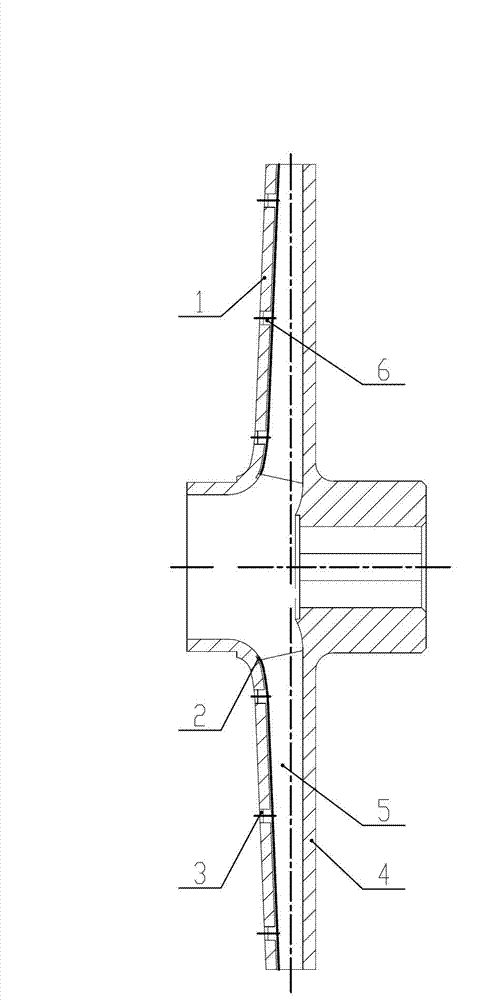

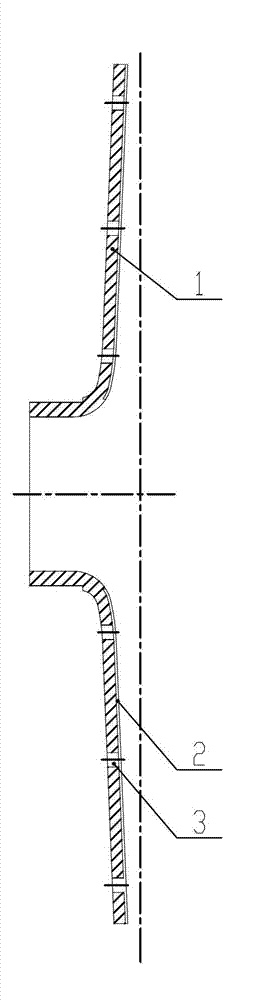

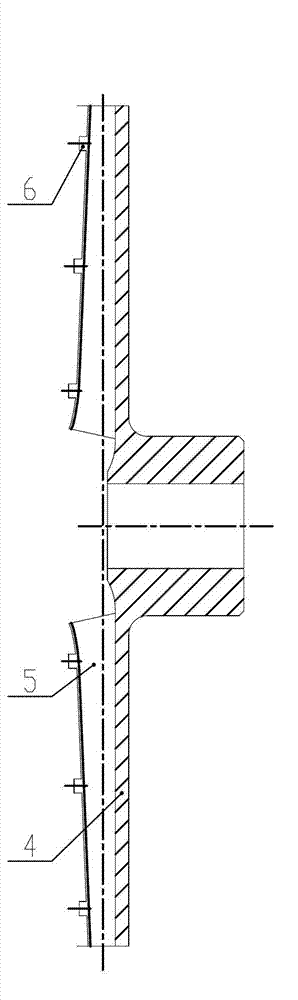

[0015] Figure 1 to Figure 5 Among them, it includes front cover plate 1, blade groove 2, positioning hole 3, rear cover plate 4, blade 5, positioning column 6 and so on.

[0016] Such as figure 1 As shown, the present invention is a centrifugal pump impeller, which includes a front cover 1 and a rear cover 4 which are respectively cast and formed. The front cover 1 and the rear cover 4 are positioned and assembled to form a whole by welding.

[0017] Such as figure 2 , Figure 4 As shown, a plurality of vane slots 2 are evenly distributed on the inner surface of the front cover 1 , and positioning holes 3 are arranged in the vane slots 2 , and the total number of positioning holes 3 is at least two. Preferably, at least one positioning hole 3 is provided in each vane slot 2 , and there are preferably three positioning holes 3 in each v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com