Making method of high-bulk and high-gloss two-side coated art printing paper

A bulky, high-gloss technology, applied in pulp beating methods, pulp beating/refining methods, paper, etc., can solve problems such as low gloss and smoothness, and large paper roughness, and achieve high gloss and high Effect of smoothness, good bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

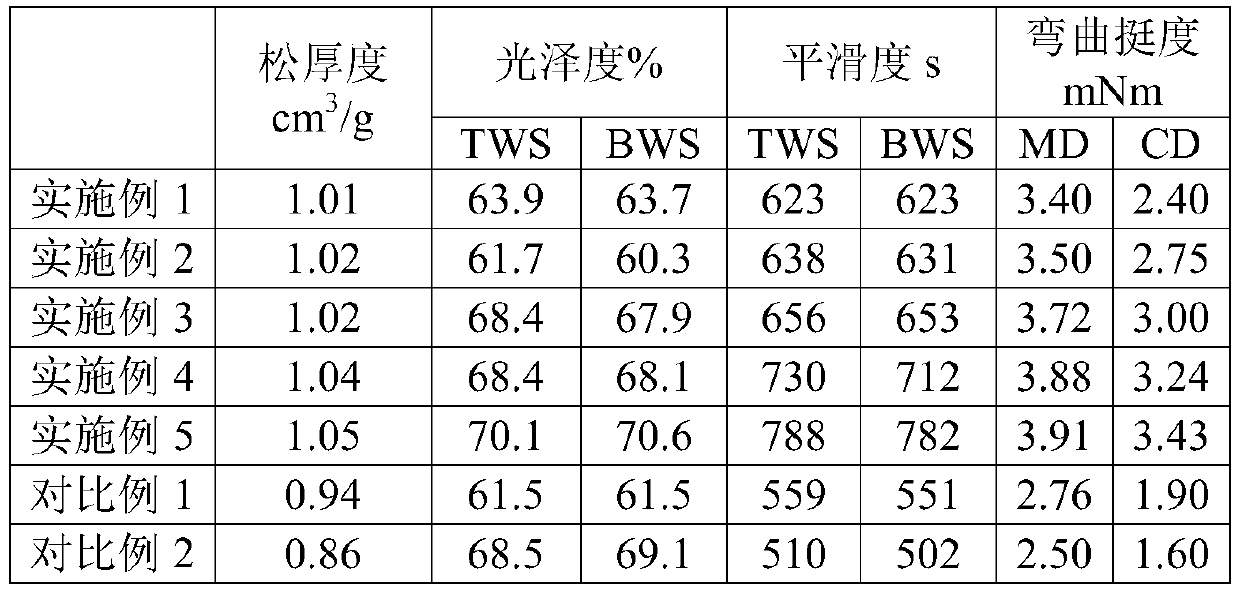

Examples

Embodiment 1

[0030] A method for making double-sided coated paper with high bulkiness and high gloss, comprising the following steps:

[0031] 1) Slurry preparation: select alkaline hydrogen peroxide mechanical pulp, and use a deflagger (inlet and outlet pressure of the deflaker: 2.0-4.0bar) to carry out a slurry treatment on the pulp to obtain a freeness of 300ml and a bulk thickness of 3.1cm 3 / g of pulp; bleached kraft hardwood pulp is subjected to loose pulping and refining to obtain a freeness of 400ml and a bulk of 1.26cm 3 / g of pulp; bleached kraft softwood pulp is subjected to loosening and refining to obtain a freeness of 405ml and a bulk of 1.25cm 3 / g of slurry; bleached kraft hardwood pulp, bleached kraft softwood pulp and alkaline hydrogen peroxide mechanical pulp are respectively 50%, 10%, 40% by weight, and mixed pulping;

[0032] 2) Wet end: After the slurry is mixed according to the proportion of step 1), add 14% ground calcium carbonate (particles with a particle size l...

Embodiment 2

[0041] A method for making double-sided coated paper with high bulkiness and high gloss, comprising the following steps:

[0042] 1) Slurry preparation: select alkaline hydrogen peroxide mechanical pulp, and use a deflaker (inlet and outlet pressure of the deflaker: 2.0 to 4.0bar) to carry out a slurry treatment on the pulp to obtain a freeness of 400ml and a bulk thickness of 3.3cm 3 / g of pulp; bleached kraft broad-leaved wood pulp is dispersed and refined to obtain a freeness of 500ml and a bulk of 1.35cm 3 / g of pulp; bleached kraft softwood pulp is subjected to loosening and refining to obtain a freeness of 500ml and a bulk of 1.33cm 3 / g of slurry; bleached kraft hardwood pulp, bleached kraft softwood pulp and alkaline hydrogen peroxide mechanical pulp are respectively 60%, 20%, and 30% by weight, and are mixed and prepared;

[0043] 2) Wet end: After the slurry is mixed according to the proportion of step 1), add 10% ground calcium carbonate (particles with a particle ...

Embodiment 3

[0052] A method for making double-sided coated paper with high bulkiness and high gloss, comprising the following steps:

[0053] 1) Slurry preparation: select alkaline hydrogen peroxide mechanical pulp, and use a deflaker (inlet and outlet pressure of the deflaker: 2.0 to 4.0bar) to carry out a slurry treatment on the pulp to obtain a freeness of 400ml and a bulk thickness of 3.3cm 3 / g of pulp; bleached kraft broad-leaved wood pulp is dispersed and refined to obtain a freeness of 500ml and a bulk of 1.35cm 3 / g of pulp; bleached kraft softwood pulp is subjected to loosening and refining to obtain a freeness of 500ml and a bulk of 1.33cm 3 / g of slurry; bleached kraft hardwood pulp, bleached kraft softwood pulp and alkaline hydrogen peroxide mechanical pulp are respectively 53%, 12%, and 35% by weight, and are mixed and prepared;

[0054] 2) Wet end: After the slurry is mixed according to the proportion of step 1), add 13% ground calcium carbonate (particles with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear viscosity | aaaaa | aaaaa |

| Low shear viscosity | aaaaa | aaaaa |

| Freeness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com