Environment-friendly straw paper, preparation method thereof and paper straw processing technology

A processing technology and environment-friendly technology, applied in mechanical processing/deformation, papermaking, paper coating, etc., can solve problems such as poor experience, increased recycling costs, difficult microbial degradation of wet strength agents, etc., to achieve good flatness and barrier properties , Improve the effect of hiding and good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

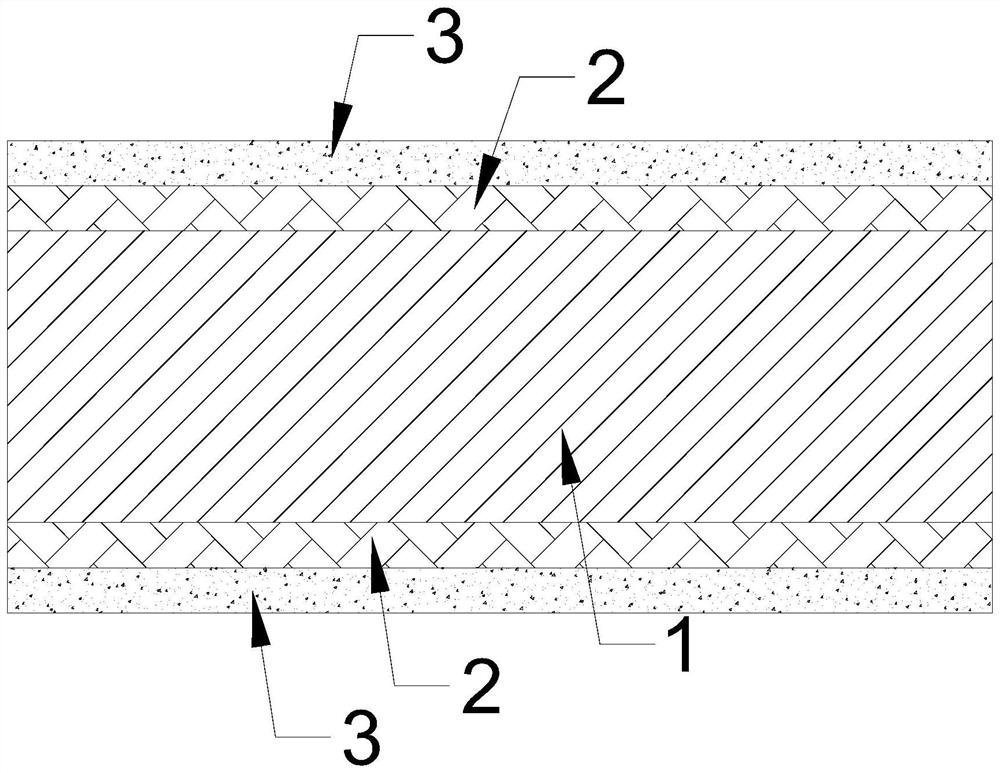

[0039] A preparation method of environment-friendly straw paper, comprising the following steps,

[0040] First, configure the paint. The paint includes primer paint and top coat paint, and the primer paint is divided into front primer and back primer, and the top coat is divided into front paint and back paint;

[0041] Second, use the coating process for coating, firstly carry out the front primer on the front of the base paper, dry, then carry out the front surface coating, dry, carry out the back primer, dry, carry out the back surface coating, dry, and the drying temperature is ≥ 90 ℃.

[0042] Coating adopts at least one of curtain coating, air knife coating, metering rod coating, knife coating and flexo printing. The preferred coating method can be curtain coating, air knife coating, metering rod.

[0043] The coating process includes one of an online coating process and an off-machine coating process. On-line coating processing technology: streaming system-wire sect...

Embodiment 1

[0053] Front primer: paint formula: China clay 100, latex 80, dispersant 0.2, NaOH 0.3, water resistance agent 0.4, carboxymethyl cellulose 0.8, lubricant 0.5, defoamer 0.1, rheological agent 0.2; total coating amount 6.0g / m2, one coat, drying temperature 90°C.

[0054] Front surface coating: coating formula: acrylate modified polymer 90%, inorganic matter 10%; total coating weight 7.2g / m2, two coatings, drying temperature 110 ℃.

[0055] Back primer: paint formula: China clay 100, latex 80, dispersant 0.2, NaOH 0.3, water resistance agent 0.4, carboxymethyl cellulose 0.8, lubricant 0.5, defoamer 0.1, rheological agent 0.2; total coating amount 6.0g / m2, one coat, drying temperature 90°C.

[0056] Back surface coating: paint formula: acrylate modified polymer 100%, inorganic matter 0%; total coating amount 4.6g / m2, two coatings, drying temperature 120°C.

Embodiment 2

[0058] Front primer: paint formula: China clay 100, latex 90, dispersant 0.2, NaOH 0.3, water resistance agent 0.4, carboxymethyl cellulose 0.8, lubricant 0.5, defoamer 0.1, rheological agent 0.2; total coating amount 6.0g / m 2 , Once coated, the drying temperature is 100°C.

[0059] Front surface coating: coating formula: 90% acrylate modified polymer, 10% inorganic matter; two coatings, total coating weight 6.8g / m 2 ,, The drying temperature is 100°C.

[0060] Back primer: paint formula: china clay 100, latex 90, dispersant 0.2, NaOH 0.3, water resistance agent 0.4, carboxymethyl cellulose 0.8, lubricant 0.5, defoamer 0.1, rheological agent 0.2; total coating amount 6.0g / m 2 , Once coated, the drying temperature is 100°C.

[0061] Back surface coating: paint formula: 90% acrylate modified polymer, 10% inorganic matter; total coating weight 7.2g / m 2 , twice coating, drying temperature 110 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com