Forming screen for use in a paper machine

A forming screen and paper machine technology, applied in the direction of paper machine, paper making, paper machine wet end, etc., can solve the problems of incomparability, etc., and achieve good dehydration effect, good fiber retention, and small filling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

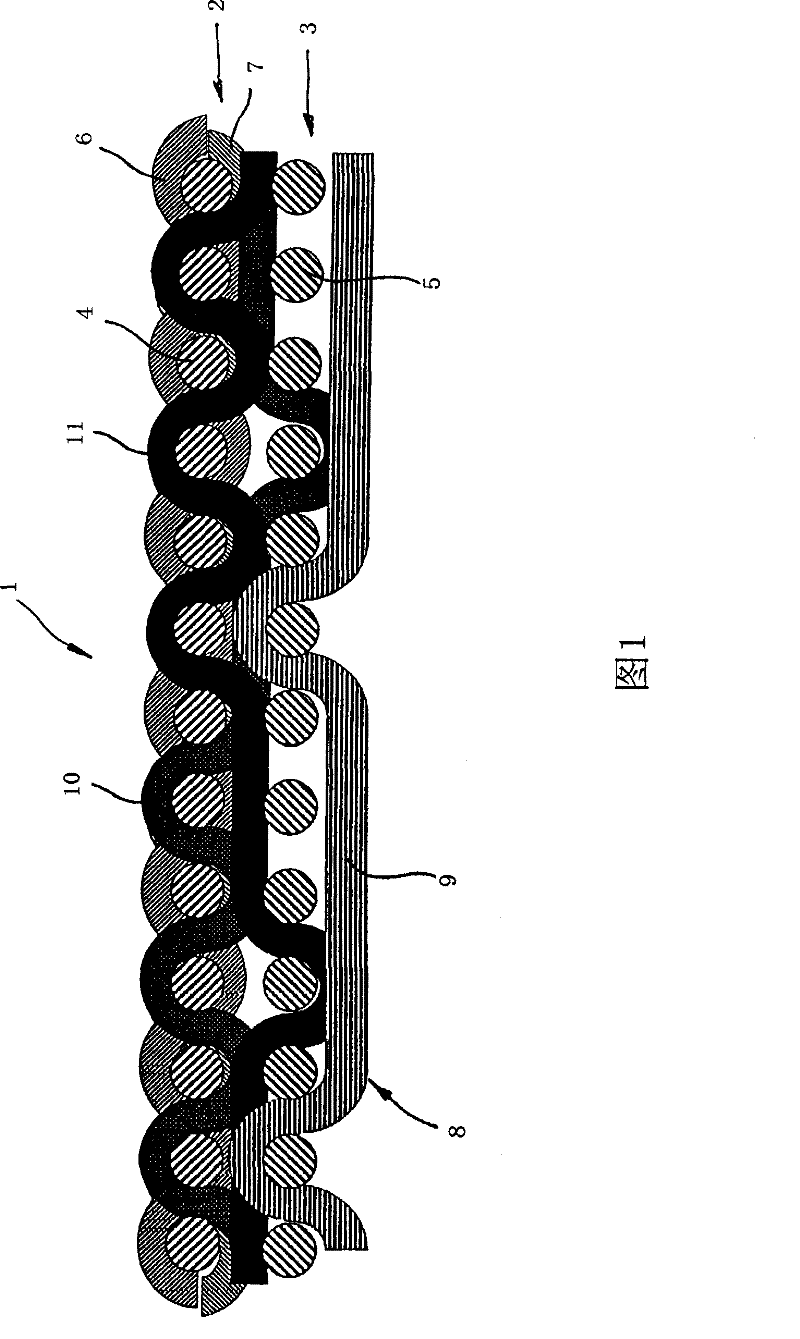

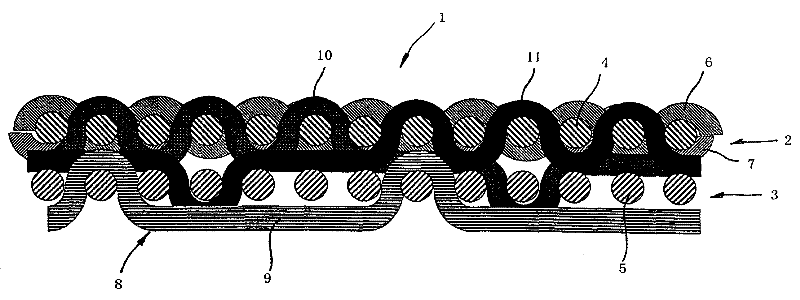

[0027] The forming screen 1 is a double-layer fabric with a longitudinal yarn layer 2 on the upper paper side and a longitudinal yarn layer 3 on the lower machine side. The two longitudinal yarn layers 2, 3 are formed by longitudinal yarns or warp yarns (for example, marked with 4 or 5) with a yarn number ratio of 1:1, and the longitudinal yarns 4 of the paper-side longitudinal yarn layer 2 They are respectively arranged exactly above the longitudinal yarns 5 in the machine-side longitudinal yarn layer 3, and the longitudinal yarns 4, 5 are correspondingly placed on top of each other in a pair.

[0028] The diameter of the longitudinal yarns 4 in the paper-side longitudinal yarn layer 2 is 0.11 mm, and the diameter of the longitudinal yarns 5 in the machine-side longitudinal yarn layer 3 is 0.18 mm. These longitudinal yarns are composed of PEN (polyethylene naphthalate). The number of longitudinal yarns is 58 per cm in the transverse direction.

[0029] In the case of a plain wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com