Monitoring vidicon cooling method and structure based on thermal pressure effect

A monitoring camera and heat dissipation structure technology, applied in image communication, color TV parts, TV system parts, etc., can solve problems such as lifespan reduction, high temperature, and affecting the quality of captured images, and achieve enhanced convective heat transfer , increase the heat dissipation effect, avoid the effect of insufficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

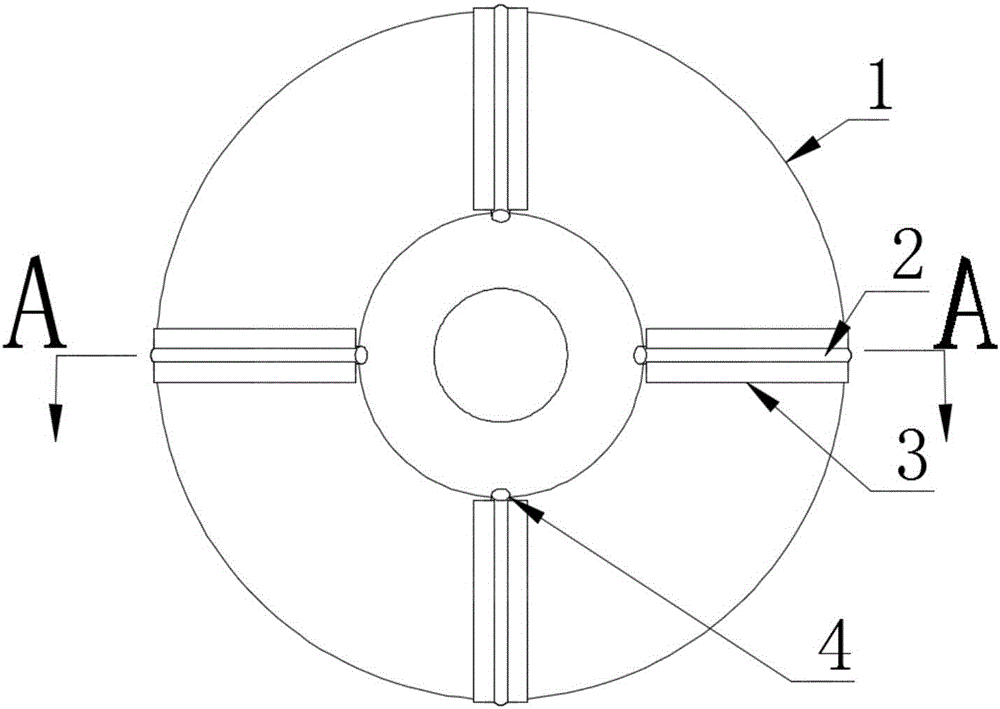

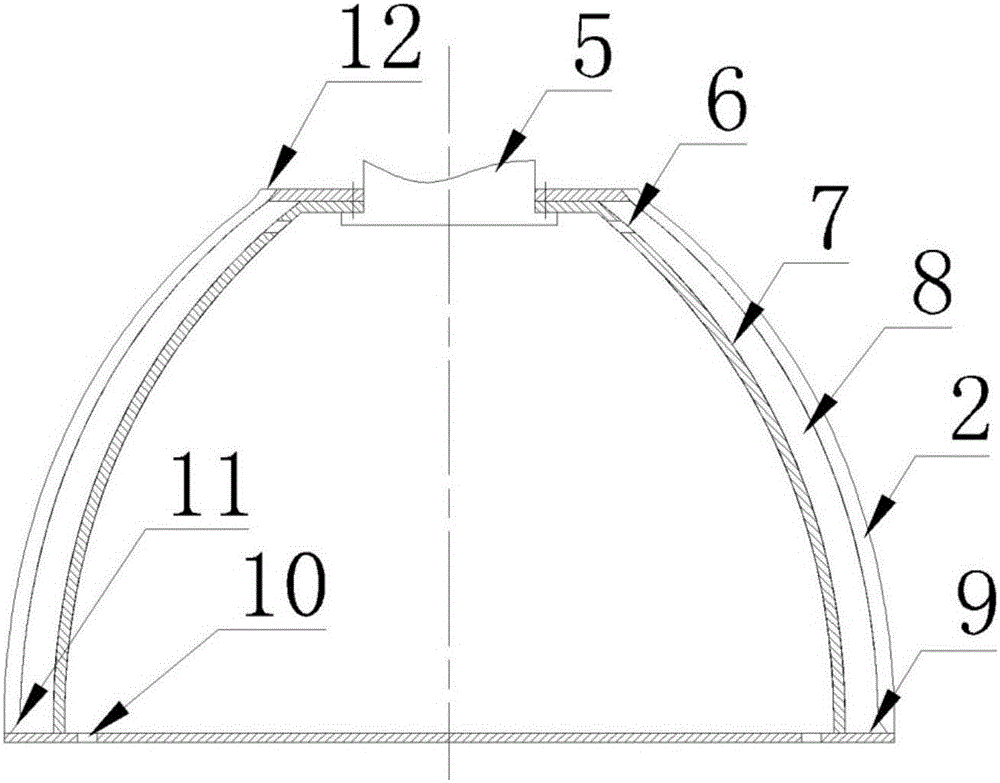

[0018] Such as figure 1 , 2 As shown, a monitoring camera heat dissipation structure based on the thermal pressure effect includes a heat shielding shell 1, a finned tube 2, a hoisting structure 5, an inner shell 7, and a bottom cover 9; between the heat shielding shell 1 and the inner shell 7 There is an air interlayer 8, and the bottom is sealed by a bottom cover 9,

[0019] The finned tube 2 is installed on the surface of the heat-shielding shell 1. One end of the finned tube 2 is connected to the environment, and the other end is connected to the air interlayer 8. The inner shell 7 is provided with a number of inner shell vent holes 6, and the inner shell vent holes 6 make the air interlayer 8 communicates with the gas space inside the inner shell, and the bottom cover 9 is provided with several bottom cover air intake holes 10, the bottom cover air intake holes 10 make the gas space inside the inner shell communicate with the environment, and the hoisting structure 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com