Inner cooling structure of bionic microchannel at front edge of turbine blade and forming method thereof

A technology of micro-channels and turbine blades, which is applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of uneven cooling of steam cooling blades and insufficient cooling effect, so as to solve the problems of uneven cooling and cooling Insufficient efficiency, high cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in combination with specific embodiments.

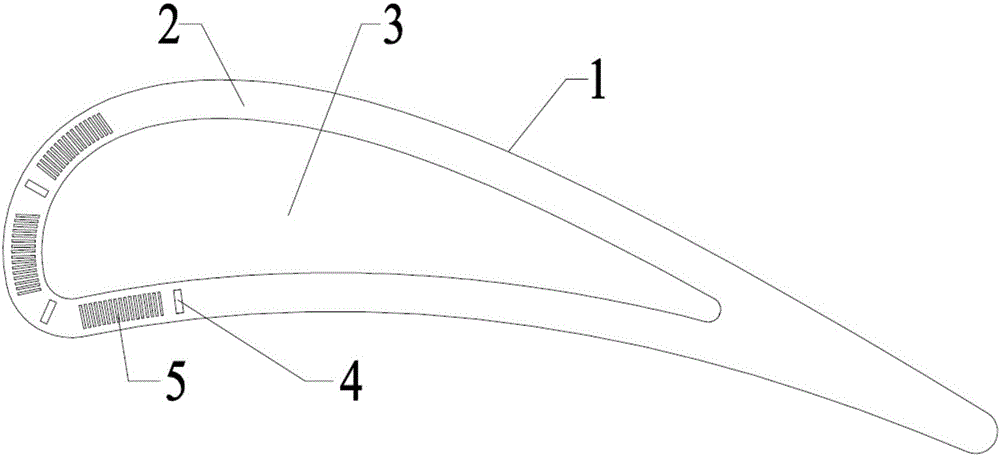

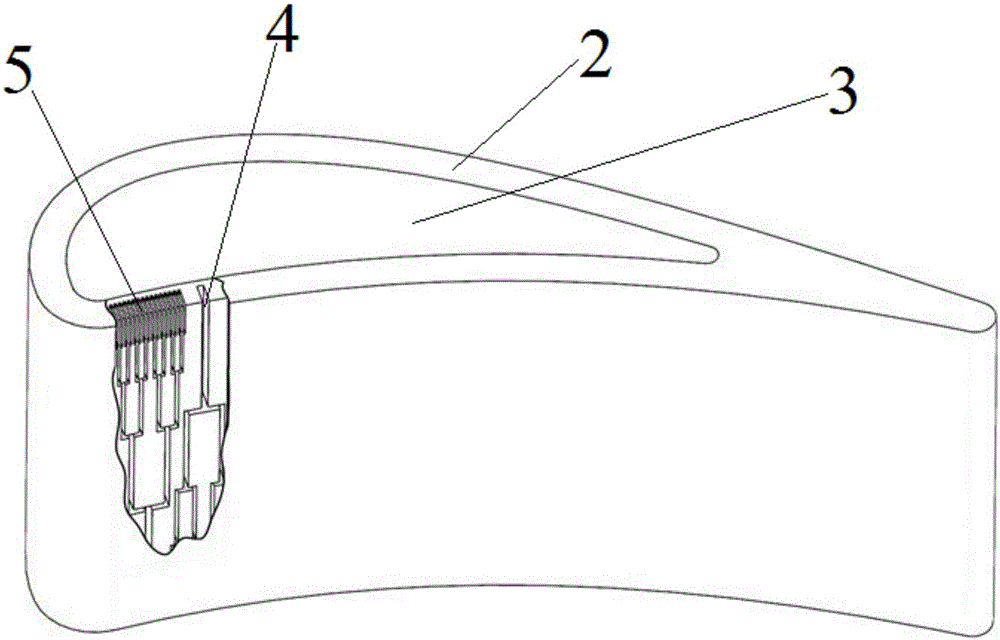

[0023] The invention provides a bionic micro-channel internal cooling structure at the leading edge of a turbine blade, such as figure 1 As shown, including the blade 1, the outer layer of the blade 1 is the outer wall 2, the middle part of the blade 1 is provided with a blade central cavity 3, and the inner part of the outer wall 2 is provided with several groups of tree-like forked fine channels.

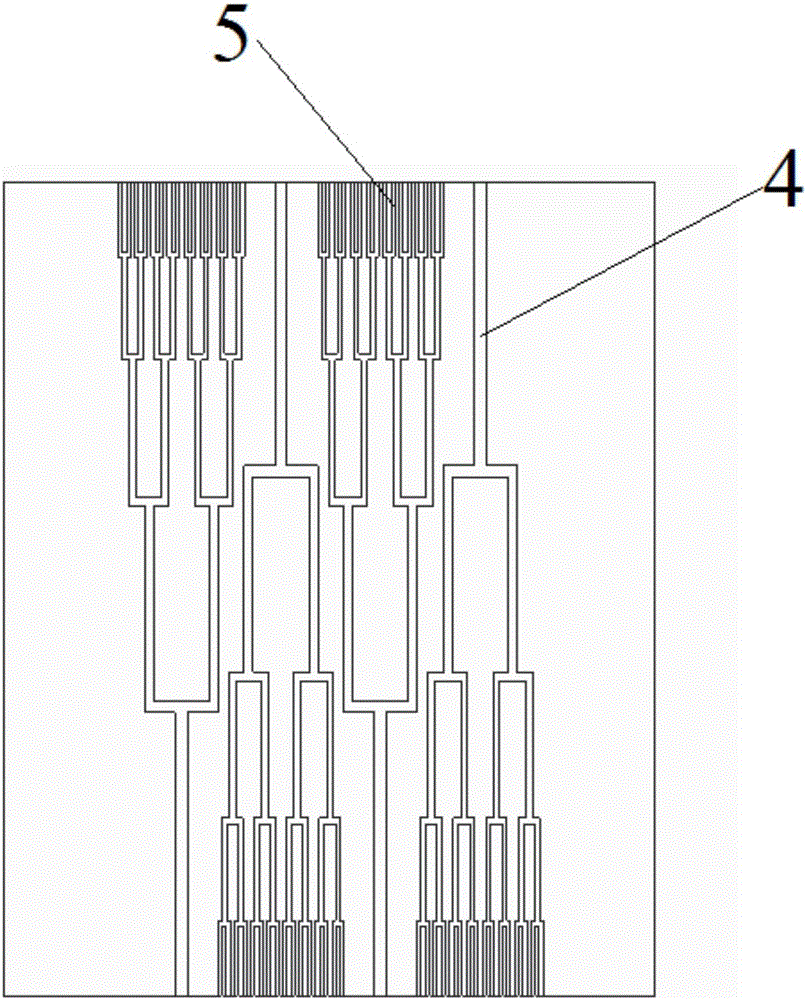

[0024] The tree-like bifurcated micro-channels are directly integrally formed by 3D printing.

[0025] Such as figure 2 As shown, each group of tree-like bifurcated micro-channels includes a micro-channel inlet 4 and several micro-channel outlets 5, and the micro-channel inlets 4 and micro-channel outlets 5 are respectively located on the upper and lower sides of the blade.

[0026] The air intake directions of the adjacent two groups of tree-like bifurcated micro-channels...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com