Quenching heat treatment process for hot work die steel with low heat resistance

A hot work die steel, heat resistance technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem of insufficient cooling capacity of quenching oil, poor cooling capacity of quenching oil, and poor comprehensive mechanical properties Ideal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The weight of the smelted and poured steel ingot is 140t. After two upsetting and drawing processes, it is processed into a die steel with a size of 3000mm × 1000mm × 800mm. After chemical analysis, its specific composition is shown in Table 1.

[0026] Table 1* Chemical composition of low heat resistance hot work die steel in Example 1 (weight percent, %)

[0027] element

C

Si

Mn

P

S

Cr

Mo

Ni

V

Ingredient Specifications

0.4~0.6

0.1~0.5

0.6~1.0

≤0.01

≤0.01

0.9~1.3

0.4~0.6

1.4~2.0

0.06~0.1

Measured ingredients

0.54

0.20

0.74

0.008

0.005

1.06

0.48

1.58

0.086

[0028] *Ac3 of this ingredient is 715°C.

[0029] The quenching and heat treatment process for low heat resistance hot work die steel is as follows:

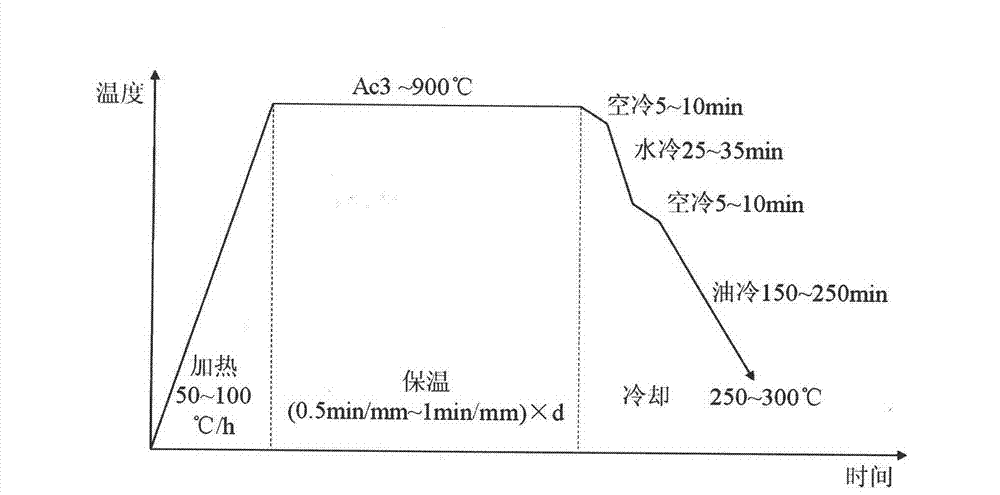

[0030] 1) Heating: Heating at a slow heating rate of 80℃ / h to ...

Embodiment 2

[0035] The weight of the smelted and poured steel ingot is 215t. After two upsetting and drawing processes, it is processed into a die steel with a size of 3800mm×1500mm×1300mm. After chemical analysis, its specific composition is shown in Table 2.

[0036] Table 2 Chemical composition of low heat resistance hot work die steel in Example 2 (weight percent, %)

[0037] element

C

Si

Mn

P

S

Cr

Mo

Ni

V

Ingredient Specifications

0.4~0.6

0.1~0.5

0.6~1.0

≤0.01

≤0.01

0.9~1.3

0.4~0.6

1.4~2.0

0.06~0.1

Measured ingredients

0.45

0.35

0.85

0.005

0.005

1.20

0.55

1.70

0.07

[0038] *Ac3 of this ingredient is 760°C.

[0039] The quenching and heat treatment process for low heat resistance hot work die steel is as follows:

[0040] 1) Heating: Heating at a slow heating rate of 50℃ / h to the a...

experiment example 1

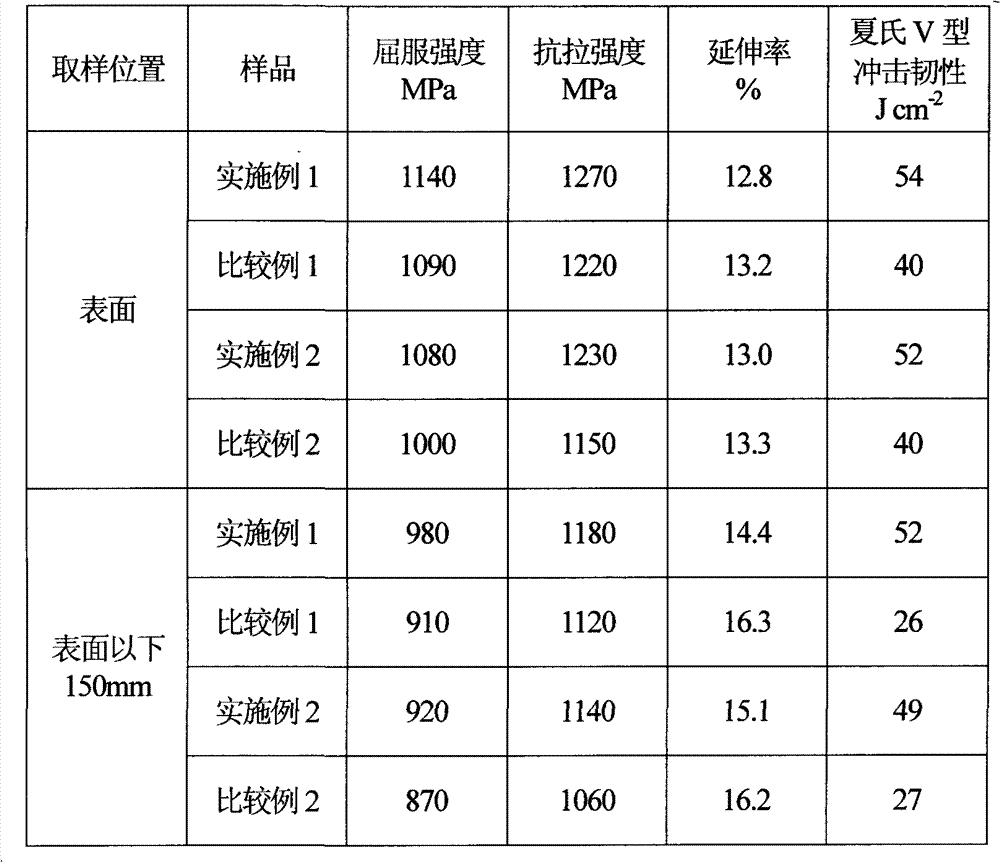

[0057] The low heat resistance hot work die steels in Examples 1, 2 and Comparative Examples 1 and 2 after heat treatment were sampled respectively on the surface and about 150 mm below the surface, and the mechanical properties were measured. The specific values are shown in Table 3. .

[0058] Table 3 Mechanical properties detection of the embodiments of the present invention and comparative examples

[0059]

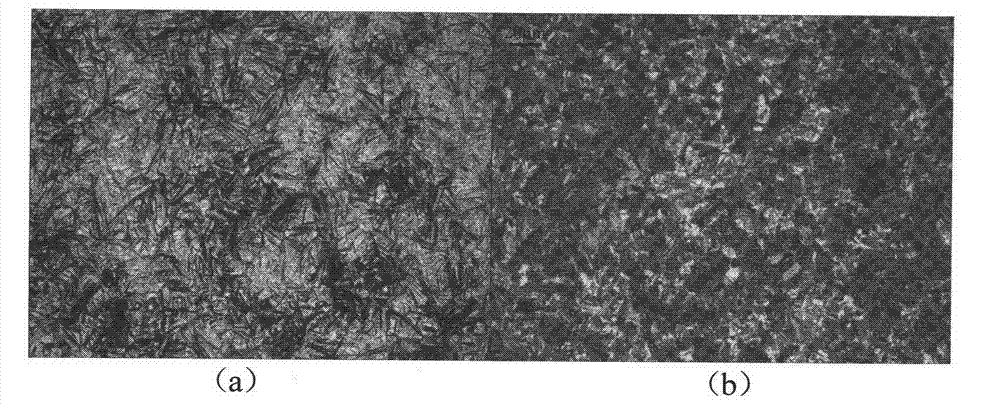

[0060] It can be seen from the results that the strength properties and impact toughness of the samples in Examples 1 and 2 are significantly better than those in the corresponding Comparative Examples 1 and 2, and no low resistance is seen in Examples 1 and 2. Hot hot work die steel has serious deformation and quenching cracking. It shows that the present invention achieves the purpose of improving the mechanical properties of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com