Quenching heat treatment process for hot work die steel with low heat resistance

A technology of hot work die steel and heat resistance, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can avoid the deformation and cracking of quenching heat treatment, improve the comprehensive mechanical properties, and achieve the effect of high cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The weight of the smelted and poured steel ingot is 140t. After two upsetting and elongating processes, it is processed into a mold steel with a size of 3000mm×1000mm×800mm. After chemical analysis, its specific composition is shown in Table 1.

[0025] Table 1 *Chemical composition of low heat resistance hot work die steel in Example 1 (weight percent, %)

[0026] the element

C

Si

mn

P

S

Cr

Mo

Ni

V

Composition specification

0.4~0.6

0.1~0.5

0.6~1.0

≤0.01

≤0.01

0.9~1.3

0.4~0.6

1.4~2.0

0.06~0.1

Measured ingredients

0.54

0.20

0.74

0.008

0.005

1.06

0.48

1.58

0.086

[0027] *Ac of this ingredient 3 It is 715°C.

[0028] The quenching heat treatment process for low heat resistance hot work die steel is as follows:

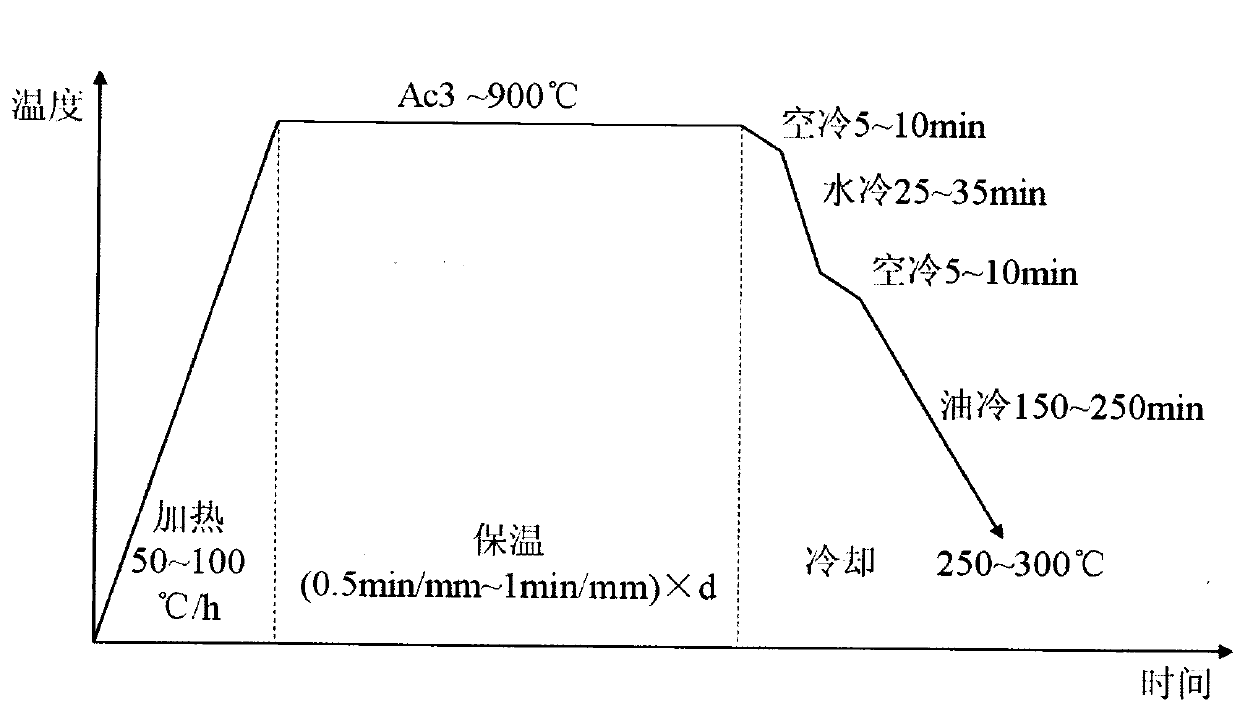

[0029] 1) Heating: Heating at a slow heating rate of 80°C / h to the austenitization temperature of low heat-resistant hot wor...

Embodiment 2

[0034] The weight of the smelted and poured steel ingot is 215t. After two upsetting and elongating processes, it is processed into a mold steel with a size of 3800mm×1500mm×1300mm. After chemical analysis, its specific composition is shown in Table 2.

[0035] Chemical composition of low heat resistance hot work die steel in Table 2 Example 2 (weight percent, %)

[0036] the element

C

Si

mn

P

S

Cr

Mo

Ni

V

Composition specification

0.4~0.6

0.1~0.5

0.6~1.0

≤0.01

≤0.01

0.9~1.3

0.4~0.6

1.4~2.0

0.06~0.1

Measured ingredients

0.45

0.35

0.85

0.005

0.005

1.20

0.55

1.70

0.07

[0037] *Ac of this ingredient 3 It is 760°C.

[0038] The quenching heat treatment process for low heat resistance hot work die steel is as follows:

[0039] 1) Heating: Heating at a slow heating rate of 50°C / h to the austenitization temperature of low heat-resistant hot work...

experiment example 1

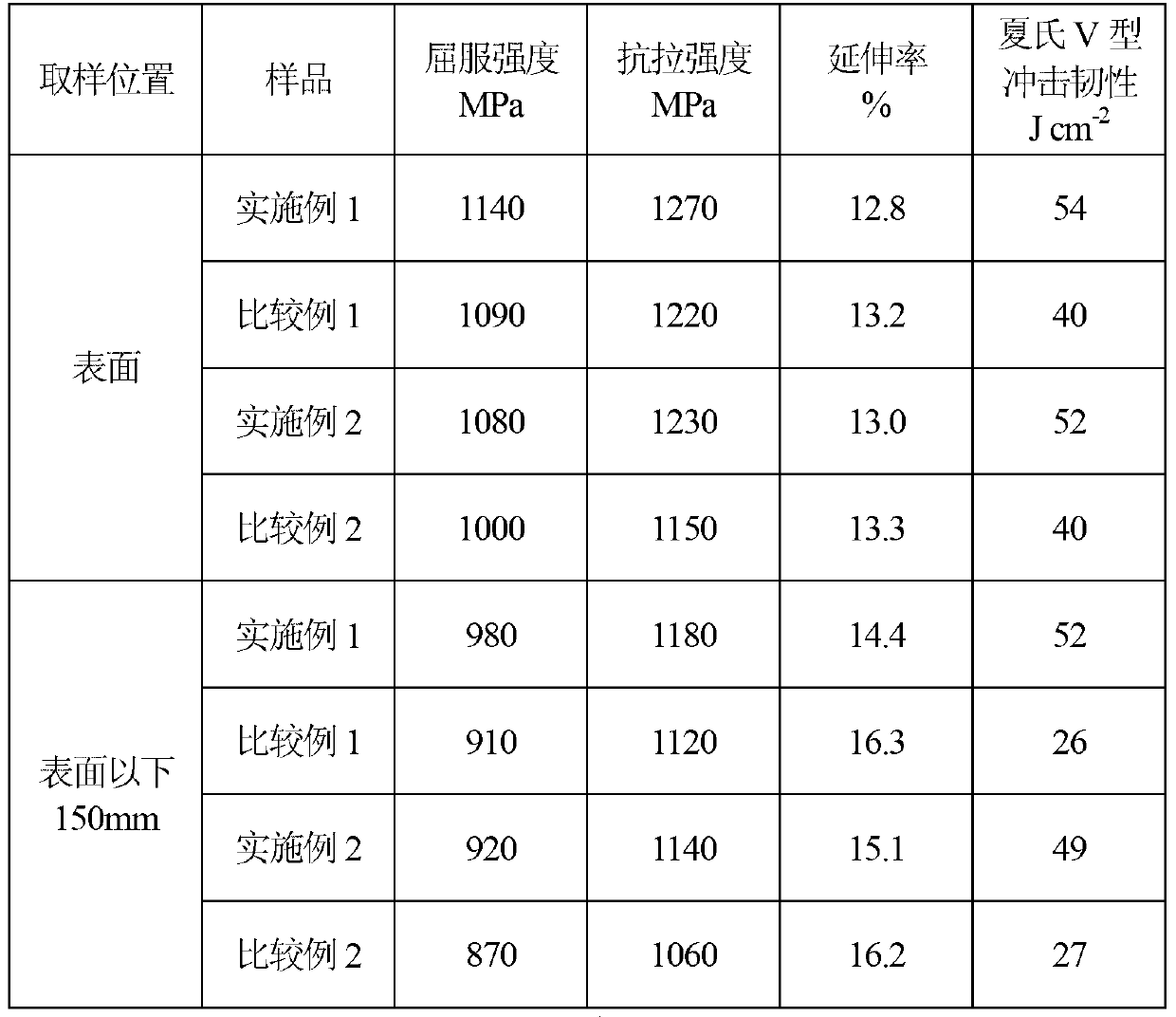

[0056] The low heat-resistant hot work die steels in Examples 1 and 2 and Comparative Examples 1 and 2 were sampled respectively at the surface position and the position about 150mm below the surface, and the mechanical properties were measured. The specific values are shown in Table 3 .

[0057] The mechanical performance detection of the embodiment of the present invention and comparative example of table 3

[0058]

[0059] As a result, it can be seen that the strength performance and impact toughness of the samples in Examples 1 and 2 are significantly better than those of the corresponding samples in Comparative Examples 1 and 2, and there is no low resistance in Examples 1 and 2. Hot hot work die steel has severe deformation and quenching cracking. It shows that the invention achieves the purpose of improving the mechanical properties of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com