Optimum temperature control device for thermoforming of high-strength steel

An optimal temperature and control device technology, applied in the field of high-strength steel hot forming, can solve the problems of insufficient cooling rate, insufficient part strength, poor hot-formability of high-strength steel material, etc., to improve service life, improve productivity, and shorten work. The effect of temperature cycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

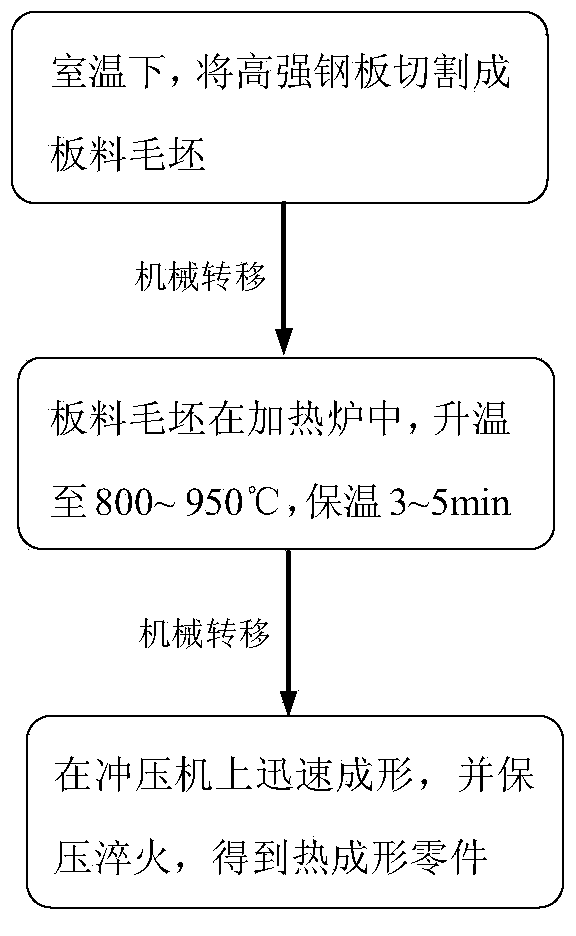

[0077] Example 1: Low-level working process.

[0078] refer to Figure 14 and Figure 16 , when the thickness of the high-strength steel sheet 20 to be cooled is thin and the size is small, the low-level working process can be considered. For example, the 22MnB5 rough sheet of 800mm×600mm×1.5mm is used as the operation object to ensure that the optimum forming temperature is 650°C before forming.

[0079] The low-level working process consists of the following steps:

[0080] 1. Use a cutting machine to cut a 22MnB5 blank sheet of 800mm×600mm×1.5mm;

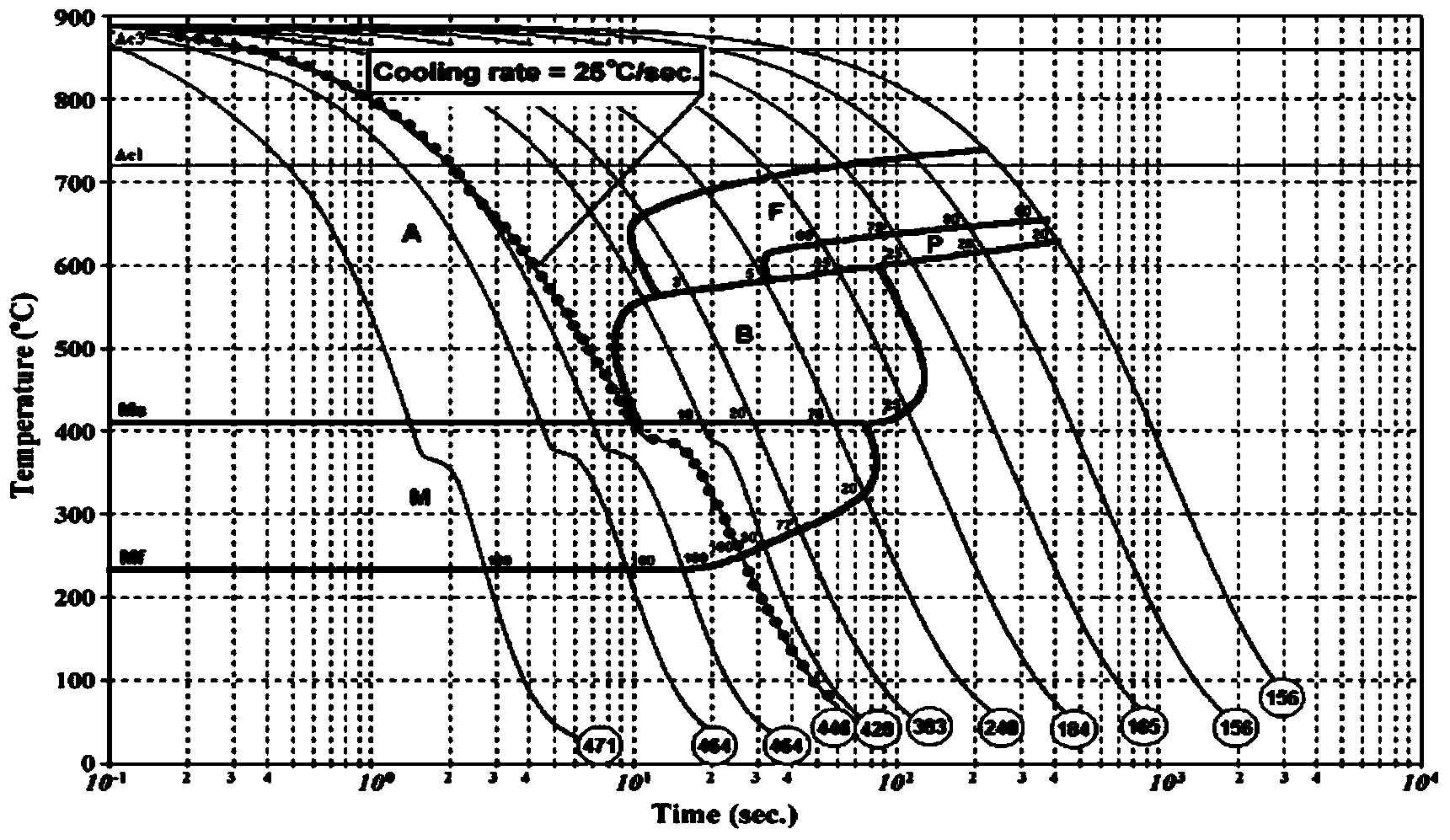

[0081] 2. Transfer it to a heating furnace through a mechanical device, raise the temperature to 900°C, and keep it warm for 5 minutes to ensure that the internal structure of the blank sheet is completely transformed into uniform austenite;

[0082] 3. Subsequently, the fully austenitized high-temperature high-strength steel material 20 is quickly transferred to the lower heat conduction plate 4 of the optimal temperature co...

Embodiment 2

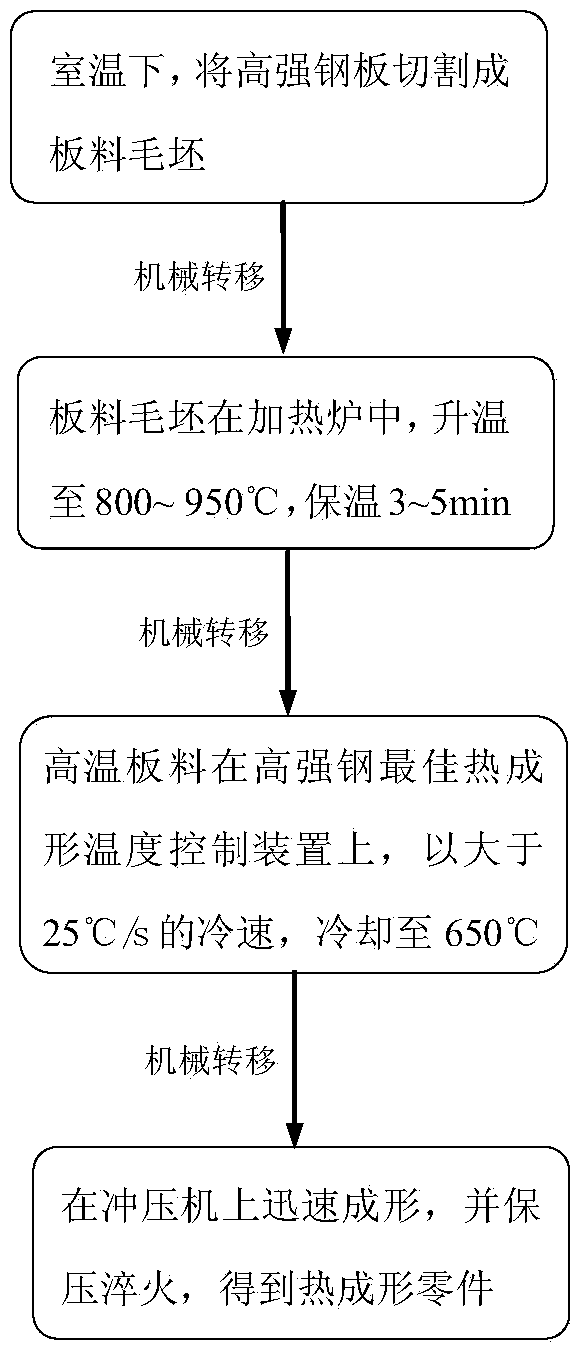

[0087] Example 2: Advanced working process.

[0088] refer to Figure 15 and Figure 16 , when the high-strength steel sheet 20 to be cooled has a thick thickness and a large size, an advanced working process may be considered. For example, the 22MnB5 rough sheet of 2000mm×1500mm×3mm is used as the operation object to ensure that the optimum forming temperature is 650°C before forming.

[0089] The high-level working process includes the following steps:

[0090] 1. Use a cutting machine to cut a 22MnB5 blank sheet of 2000mm×1500mm×3mm;

[0091] 2. Transfer it to a heating furnace through a mechanical device, raise the temperature to 900°C, and keep it warm for 5 minutes to ensure that the internal structure of the blank sheet is completely transformed into uniform austenite;

[0092] 3. Subsequently, the fully austenitized high-temperature high-strength steel material 20 is quickly transferred to the lower heat conduction plate 4 of the optimal temperature control device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com