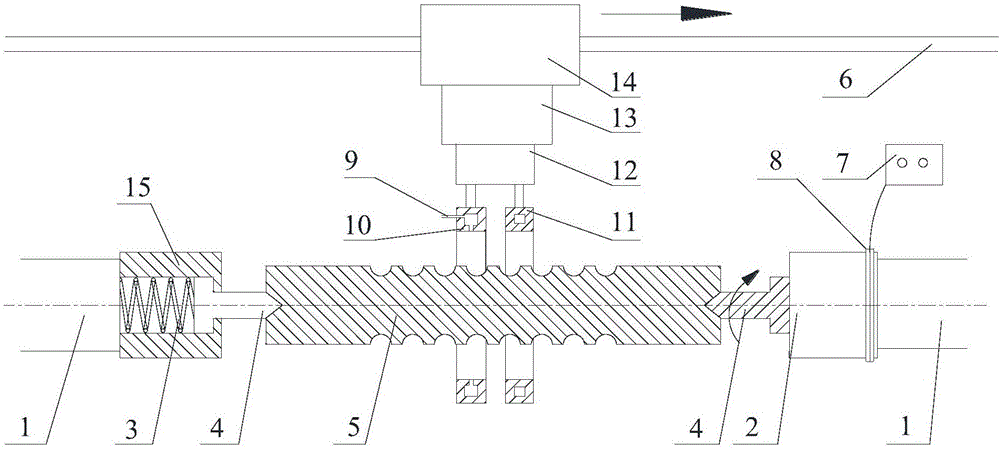

Ultrasonic vibration-assisted screw induction hardening device and technique

An ultrasonic vibration and induction quenching technology, applied in the field of quenching devices, can solve the problems of uneven quenching of the lead screw, uneven hardness of the lead screw, inability to obtain martensite structure, etc., achieve uniform austenitization, improve surface performance, The effect of avoiding soft point defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0038] In this embodiment, the 5010-type ball screw is taken as an example. An ultrasonic vibration-assisted induction hardening device includes an ultrasonic vibration device and an induction hardening device. Specifically, it includes two rotating shafts, two thimbles 4, one thimble 4 connected to an elastic Element 3, the elastic element 3 is fixed in the housing 15 on one side of the second rotating shaft, the elastic element is in a natural state or compressed state in the housing, a through hole is provided on one side of the housing, and the head of the thimble 4 is arranged in the housing Inside, one end of the thimble is set outside the shell through a through hole to clamp the screw from both sides of the screw. The tail of the thimble 4 is pointed to support the screw....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com