Heat radiation method for LED module

A technology of light-emitting diodes and heat dissipation methods, which is applied to semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, light sources, etc., and can solve the problems of inability to implement heat pipe technology on a large scale, affect the promotion of LED lights, and fail to meet heat dissipation requirements, etc. To solve the problem, to achieve reasonable design, make up for the lack of heat dissipation, and facilitate the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

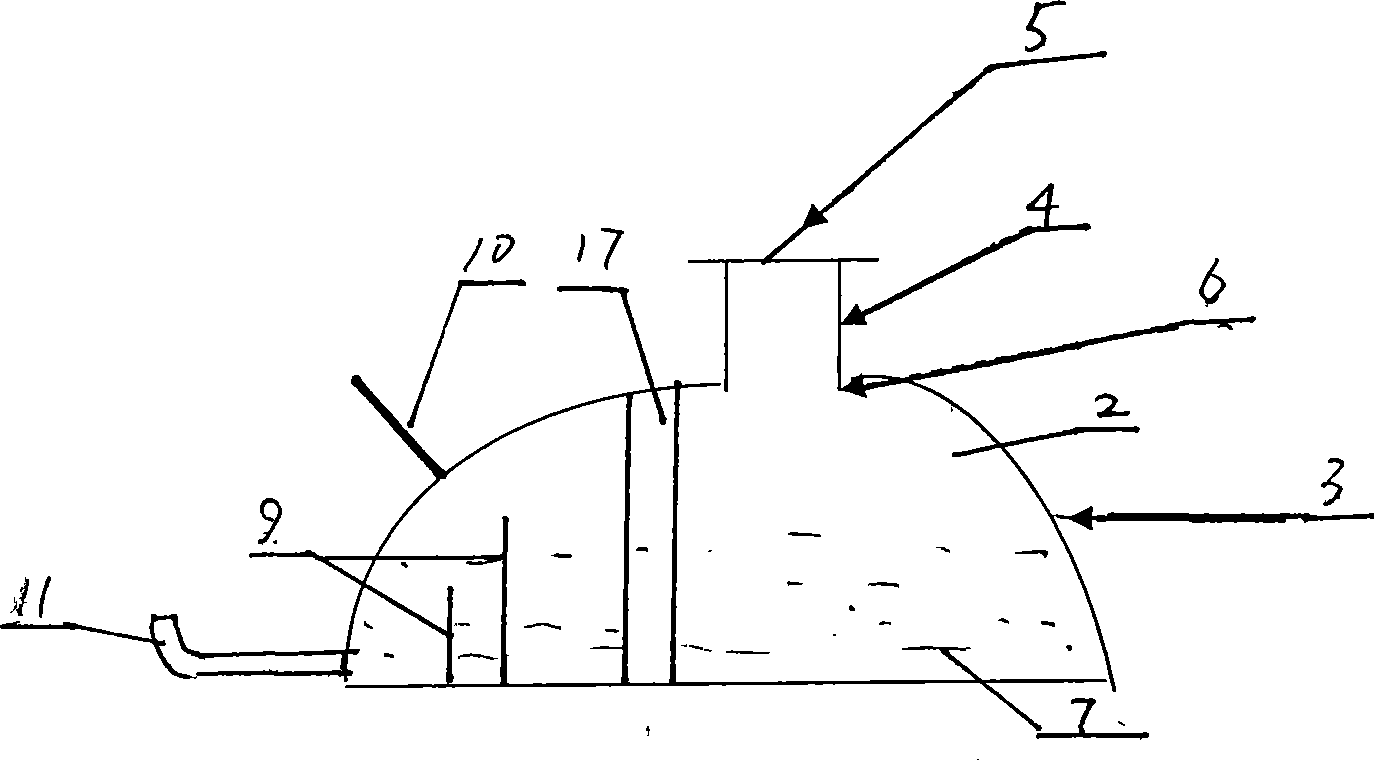

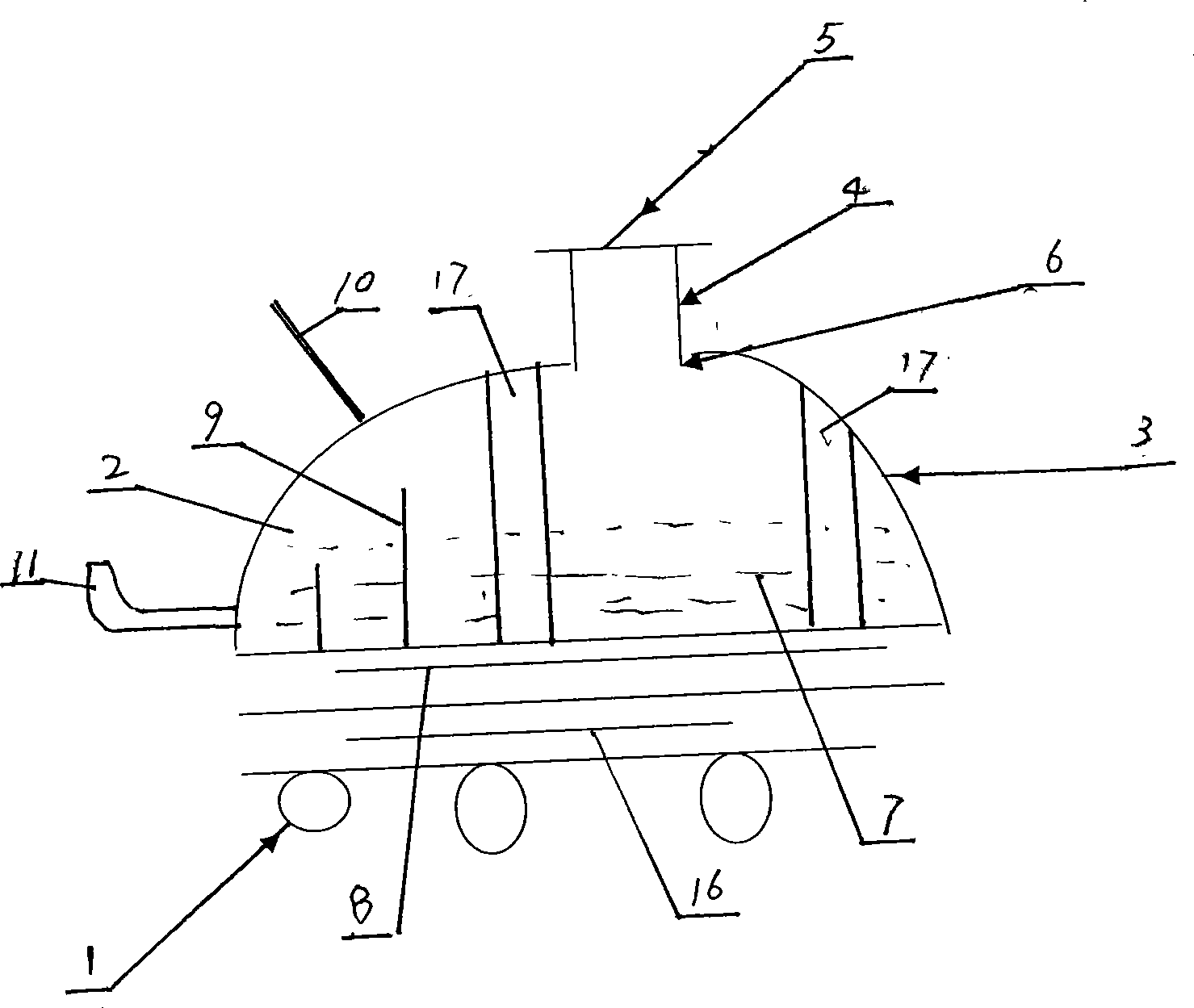

[0022] refer to figure 1 , figure 2 , the present invention includes a main container 3, a short section 4, a cover 5, and the like. The main container 3 is made of heat-conducting materials (such as metal aluminum, aluminum alloy, etc.); and can be made into various shapes. An interface 6 is provided on the outer wall of the main container 3, and the location of the interface 6 is on the top of the container. The short joint 4 communicates with the main container 3 through the interface 6 . The short joint 4 is a columnar hollow structure. A cover 5 is placed on top of the nipple 4 . The cover 5 is elastic, made of stretchable material or metal material, and its area is larger than the cross-sectional area of the interface 6 . After the liquid 7 (water) is poured into the main container 3, the main container 3, the interface 6, the pup joint 4 and the cover 5 form a liquid-filled sealed container in a normal environment. The light-emitting component 1 (heat source) c...

Embodiment 2

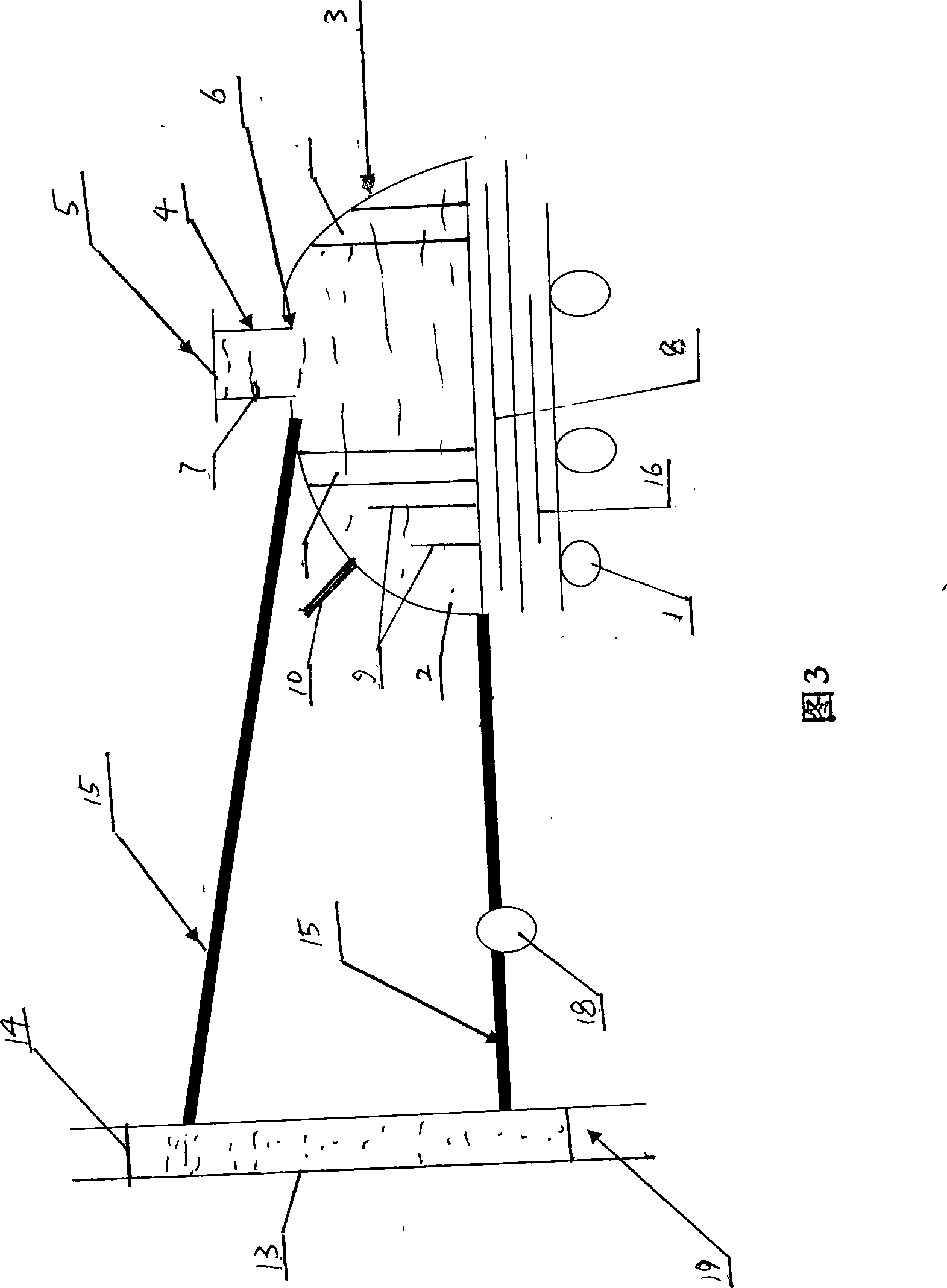

[0024] Referring to Fig. 3, in this embodiment, a secondary liquid-filled sealed container is added. Solve the problem that it is inconvenient to install because a liquid-filled airtight container is too large. The water can also be circulated, communicated with the two interfaces of the auxiliary liquid-filled sealed container through two interfaces and two pipelines, and forms a liquid-filled sealed container system with the main liquid-filled sealed container. The auxiliary liquid sealed container is composed of an auxiliary container main body 13 , an auxiliary container cover 14 and two interfaces connected with the main container 3 . The auxiliary container cover 14 covers the auxiliary container main body 13 . One port of the main container 3 is at the bottom of the side wall of the container, and the other port is at the top of the container, and communicates with the two ports of the secondary container body 13 through two pipelines 15 . At this time, the lid 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com