Radiation refrigeration coating, as well as preparation method and testing device thereof

A radiation cooling and coating technology, which is applied in the direction of measuring devices, coatings, and electrical devices, etc., can solve the problems of increasing preparation costs and manufacturing difficulties, not reflecting the cooling effect, and affecting the weather resistance of materials, etc., and achieves obvious effects of radiation cooling , environmental friendliness, stable temperature difference data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

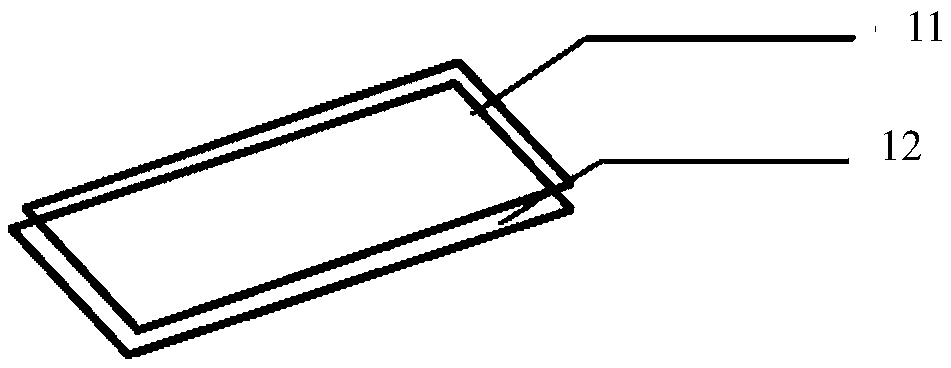

[0033] In this example, Mg 11 (HPO 3 ) 8 (OH) 6 Prepare the radiation refrigeration coating of the present invention for the functional powder, and respectively use TiO 2 , CaCO 3 A control sample was prepared for the functional powder.

[0034] First, weigh the functional powder and the binder according to the functional powder: PVDF (polyvinylidene fluoride, binder) = 70%: 30% (mass ratio). Take by weighing oxalic acid as dispersant according to 1% of functional powder and binder mass sum, then press certain solid content (solid (Mg 11 (HPO 3 ) 8 (OH) 6 、TiO 2 , CaCO 3 )=25%) and weighed NMP (nitrogen-methylpyrrolidone, organic solvent). Next, dissolve the pre-weighed binder into NMP, and stir (0.5 hour) while heating (80°C) until it becomes transparent without bubbles. Mix the weighed functional powder and oxalic acid into it, stir well, seal it with plastic wrap and release it for ball milling with a planetary ball mill for 8 hours. Prepare the slurry to be co...

Embodiment 2

[0037] In this example, Mg 11 (HPO 3 ) 8 (OH) 6 Prepare the radiation refrigeration coating of the present invention for the functional powder, and respectively use TiO 2 , CaCO 3 A control sample was prepared for the functional powder.

[0038] First, weigh the functional powder and the binder according to the functional powder:PVDF (polyvinylidene fluoride, binder)=85%:15% (mass ratio). Take by weighing oxalic acid as dispersant according to the 2% of functional powder and binder mass sum, then according to a certain solid content (solid (Mg 11 (HPO 3 ) 8 (OH) 6 、TiO 2 , CaCO 3 )=30%) and weigh NMP (nitrogen-methylpyrrolidone, organic solvent). Next, dissolve the pre-weighed binder into NMP, and stir (1 hour) while heating (100°C) until it becomes transparent without bubbles. Mix the weighed functional powder and oxalic acid into it, stir well, seal it with plastic wrap, and release it for ball milling with a planetary ball mill for 10 hours. Prepare the slurry ...

Embodiment 3

[0041] In this example, Mg 11 (HPO 3 ) 8 (OH) 6Prepare the radiation refrigeration coating of the present invention for the functional powder, and respectively use TiO 2 , CaCO 3 A control sample was prepared for the functional powder.

[0042] First, weigh the functional powder and the binder according to the functional powder: PVDF (polyvinylidene fluoride, binder)=90%:10% (mass ratio). Take by weighing oxalic acid as dispersant according to the 3% of functional powder and binder quality and, then according to certain solid content (solid (Mg 11 (HPO 3 ) 8 (OH) 6 、TiO 2 , CaCO 3 )=35%) and weigh NMP (nitrogen-methylpyrrolidone, organic solvent). Next, dissolve the pre-weighed binder into NMP, and stir (1 hour) while heating (120°C) until it becomes transparent without bubbles. Mix the weighed functional powder and oxalic acid, stir well, seal it with plastic wrap and release it for ball milling with a planetary ball mill for 12 hours. Prepare the slurry to be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com