Frequency changer cooling and dehumidification system, frequency conversion type compressor unit and refrigeration plant

A frequency converter and cooling flow path technology, applied in the field of refrigeration equipment, can solve problems such as insufficient cooling of reactance modules, and achieve the effect of ensuring safe and reliable operation and avoiding insufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

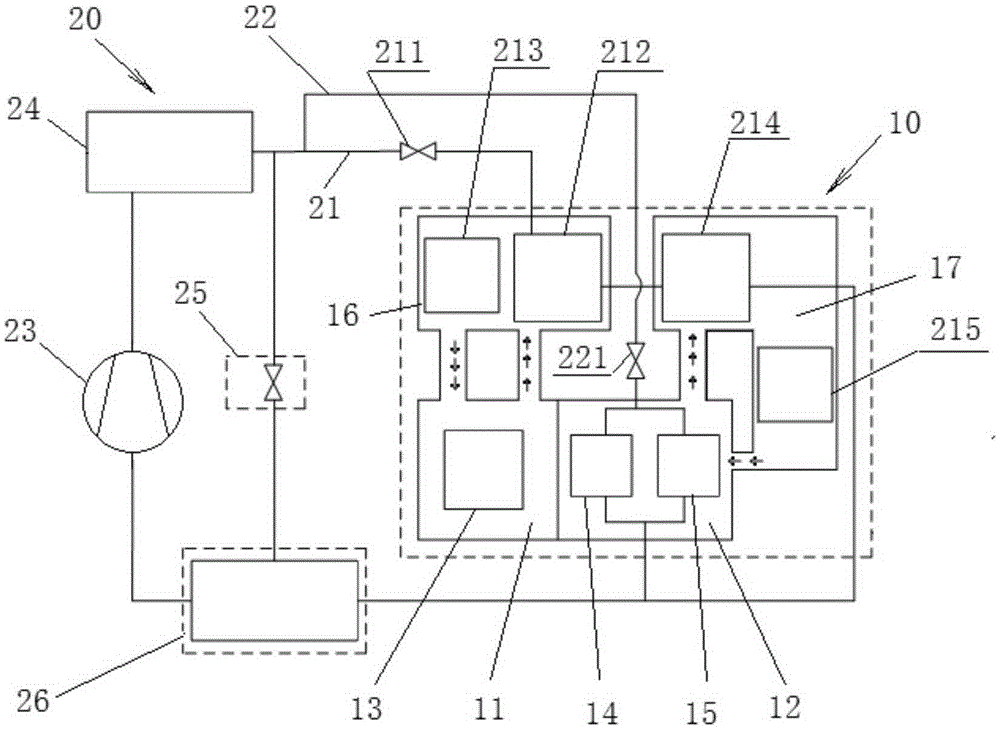

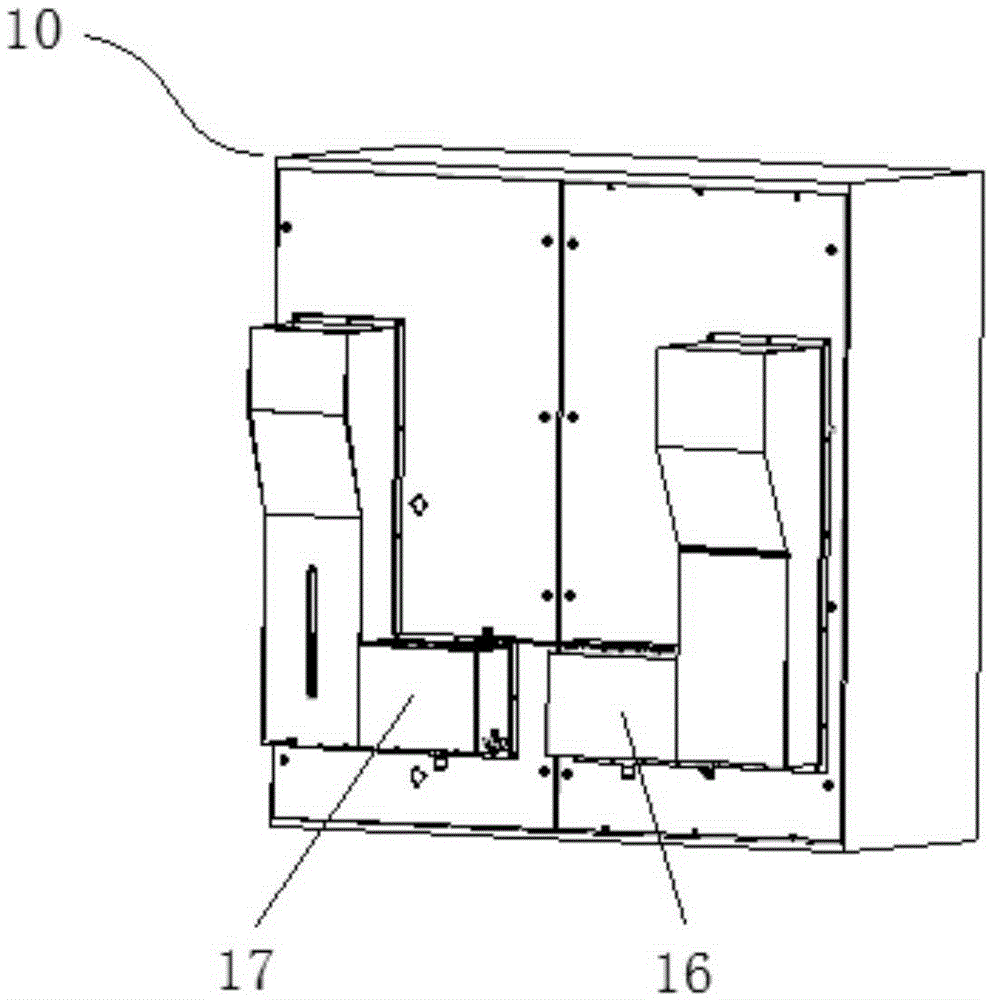

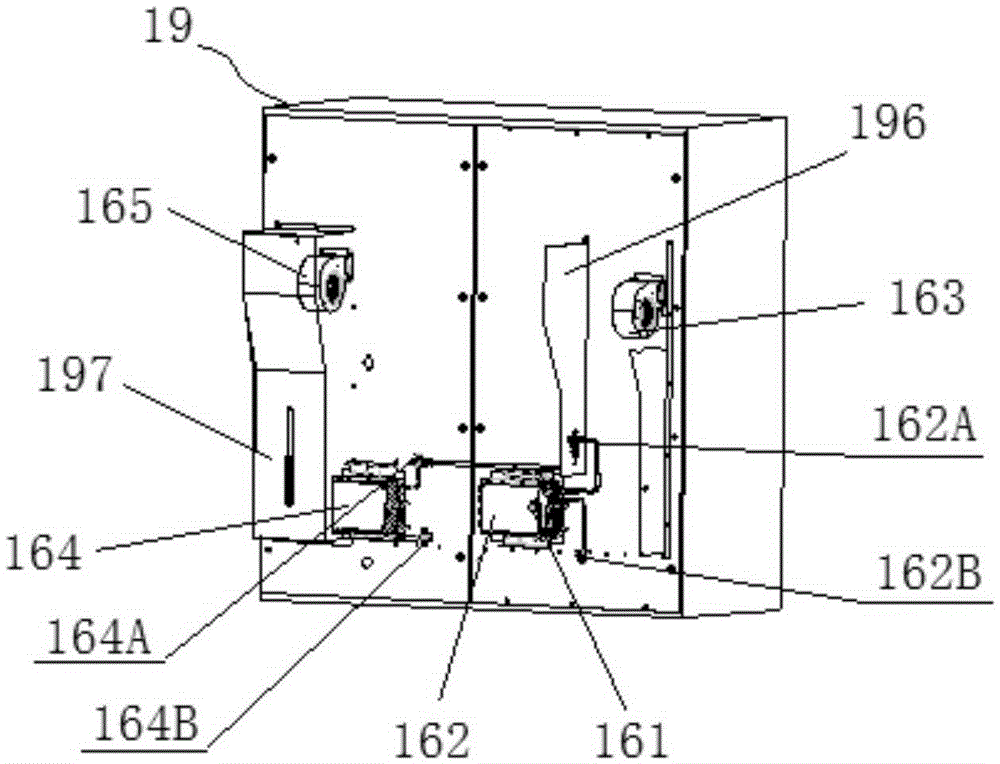

[0076] figure 1 It is a schematic diagram of the principle of the inverter cooling and dehumidification system according to the first embodiment of the present invention. figure 2 It is a structural schematic diagram of the frequency converter involved in the frequency converter cooling and dehumidification system according to the first embodiment of the present invention. image 3 It is a structural schematic diagram of the inverter cooling and dehumidification system and related inverters in the first embodiment of the present invention after removing part of the air duct wall plates in the first air duct and the second air duct. Figure 4 for image 3 Schematic diagram of the partially enlarged structure.

[0077] Such as Figure 1 to Figure 4 As shown, in this embodiment, the inverter 10 targeted by the inverter cooling and dehumidification system has a first space 11 and a second space 12 that are isolated from each other. The frequency converter includes a reactance...

no. 2 example

[0106] Figure 5 It is a schematic diagram of the principle of the inverter cooling and dehumidification system according to the second embodiment of the present invention, where the third cooling flow path connected to the inverter module and the main refrigeration circuit connected to the third cooling flow path are not shown. Image 6 It is a schematic schematic diagram of the inverter cooling and dehumidification system according to the second embodiment of the present invention, in which only the third cooling flow path connected to the inverter module and the main refrigeration circuit connected to the third cooling flow path are shown.

[0107] Such as Figure 5 with Image 6 As shown, in the second embodiment, the frequency converter 10 has a first space 11 and a second space 12 that are isolated from each other. The frequency converter includes a reactance module 13 , a rectification module 14 and an inverter module 15 . The reactance module 13 has a hot surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com