Portable drilling equipment for maintenance of large natural gas pipeline

A technology for natural gas pipelines and drilling equipment, which is applied in the field of portable drilling equipment for maintenance of large natural gas pipelines, can solve the problems of inconvenient operation, inability to ensure stable operation of the equipment, and difficulty in carrying the equipment, so as to prolong the service life and improve the practicability of the equipment. , the effect of speeding up the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

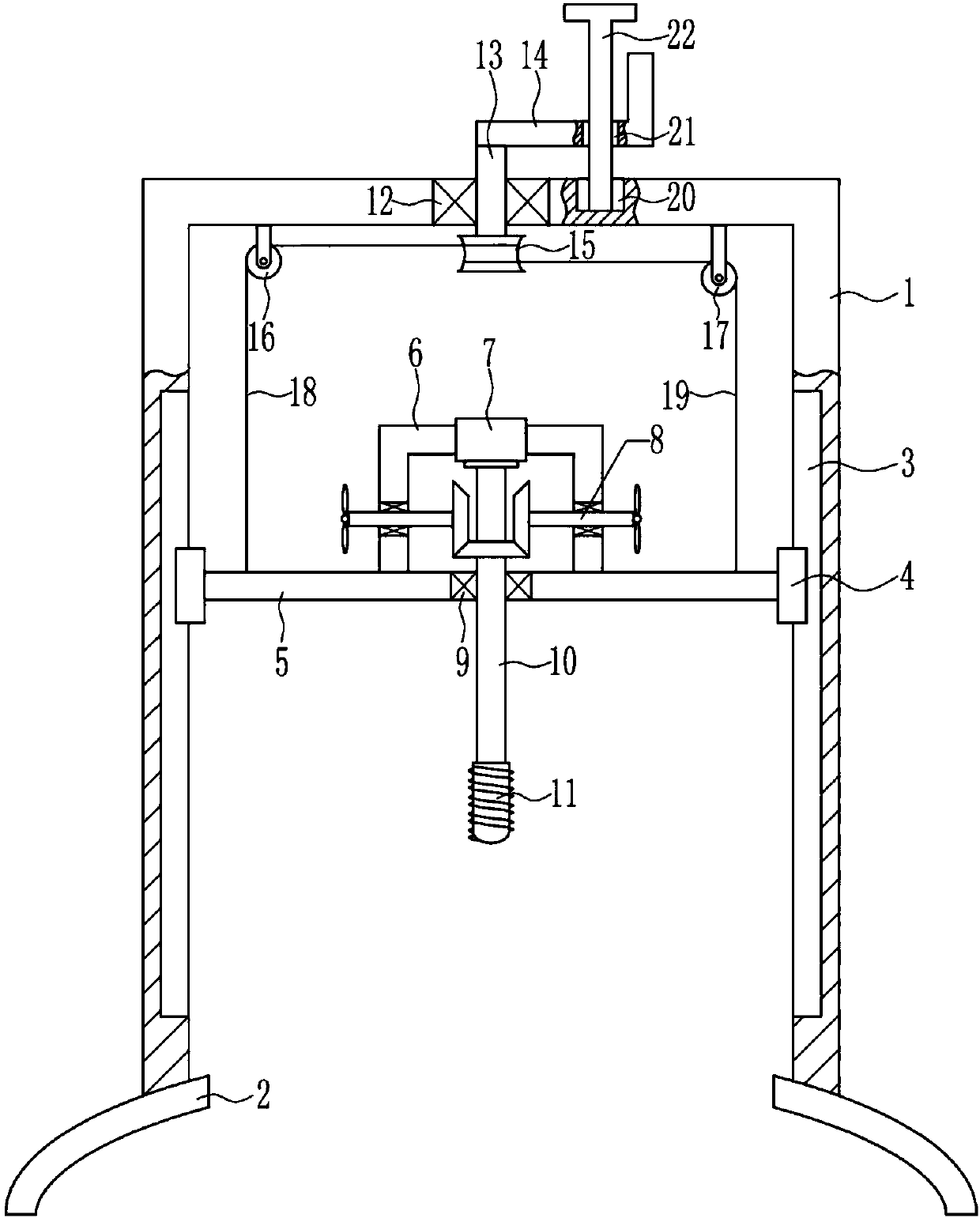

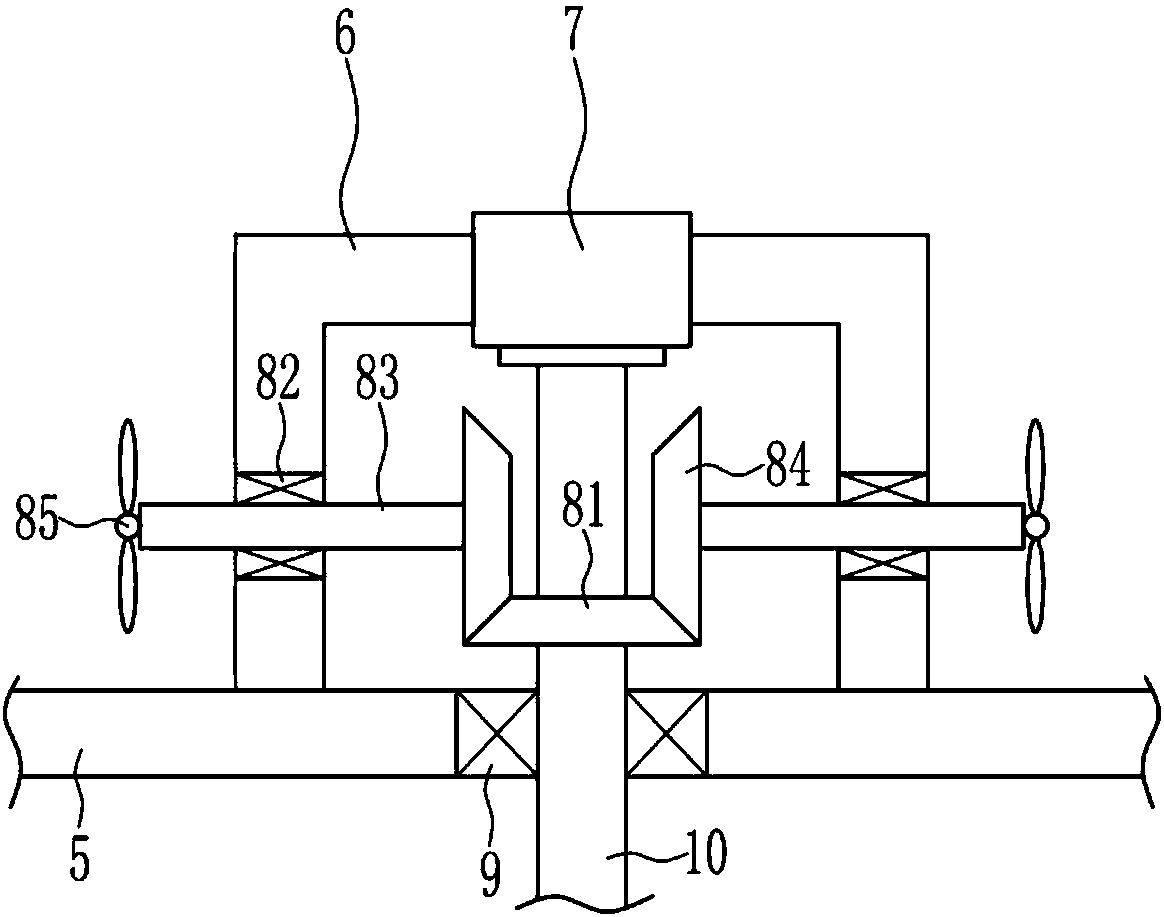

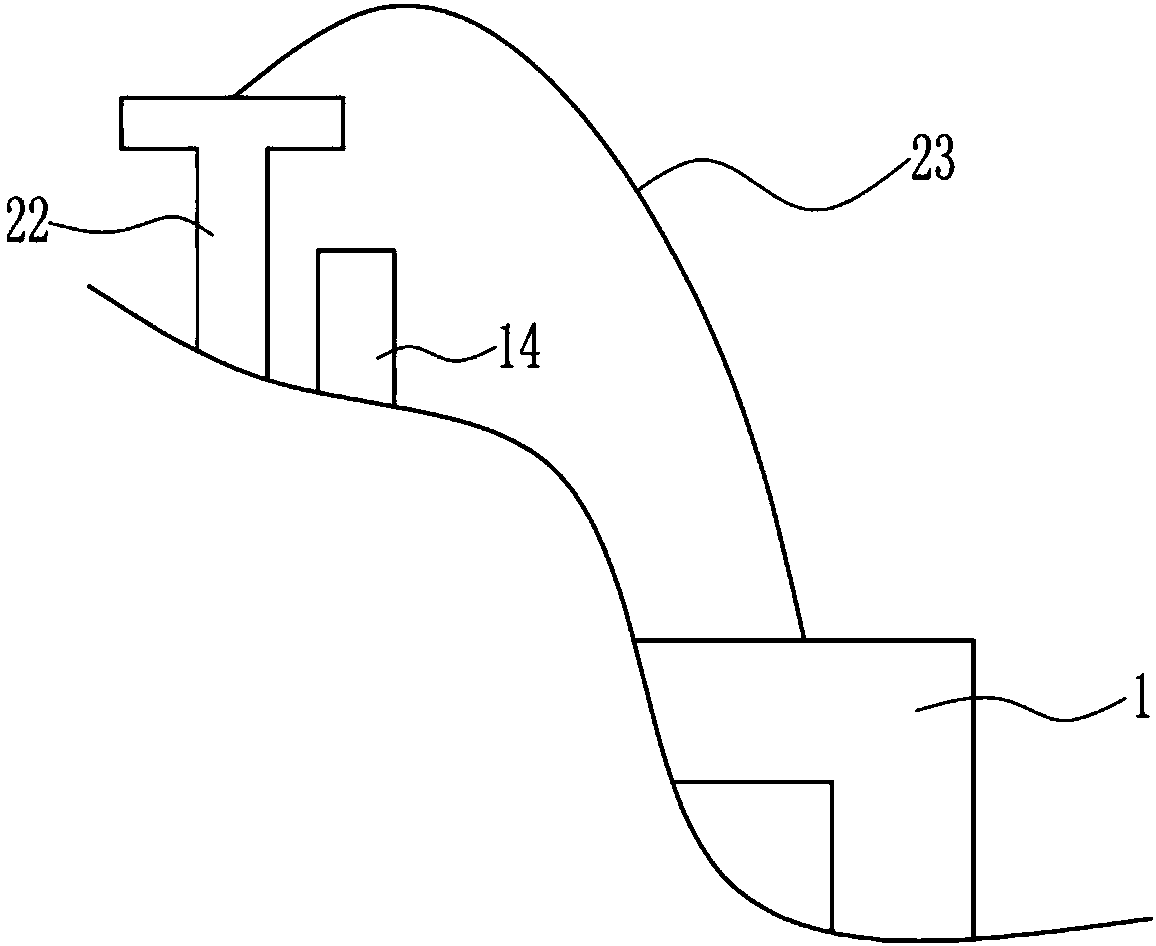

Embodiment 1

[0023] A portable drilling equipment for large-scale natural gas pipeline maintenance, such as Figure 1-3 As shown, it includes a mounting frame 1, an arc-shaped base 2, a sliding rail 3, a sliding block 4, a mounting plate 5, a fixing frame 6, a motor 7, a heat sink 8, a first bearing 9, a first rotating shaft 10, a drill bit 11, The second bearing 12, the second rotating shaft 13, the rocking handle 14, the winding wheel 15, the first fixed pulley 16, the second fixed pulley 17, the first cable 18, the second cable 19 and the plunger 22, the mounting frame 1 left and right two The bottom of the wall is provided with an arc-shaped base 2, the inner middle of the left and right walls of the mounting frame 1 are inlaid with slide rails 3, the inner sides of the slide rails 3 on the left and right sides are slidably connected with sliders 4, and the inner ends of the sliders 4 on the left and right sides are connected There is a mounting plate 5, the top center of the mounting p...

Embodiment 2

[0025] A portable drilling equipment for large-scale natural gas pipeline maintenance, such as Figure 1-3 As shown, it includes a mounting frame 1, an arc-shaped base 2, a sliding rail 3, a sliding block 4, a mounting plate 5, a fixing frame 6, a motor 7, a heat sink 8, a first bearing 9, a first rotating shaft 10, a drill bit 11, The second bearing 12, the second rotating shaft 13, the rocking handle 14, the winding wheel 15, the first fixed pulley 16, the second fixed pulley 17, the first cable 18, the second cable 19 and the plunger 22, the mounting frame 1 left and right two The bottom of the wall is provided with an arc-shaped base 2, the inner middle of the left and right walls of the mounting frame 1 are inlaid with slide rails 3, the inner sides of the slide rails 3 on the left and right sides are slidably connected with sliders 4, and the inner ends of the sliders 4 on both sides are connected There is a mounting plate 5, the top center of the mounting plate 5 is prov...

Embodiment 3

[0028] A portable drilling equipment for large-scale natural gas pipeline maintenance, such as Figure 1-3 As shown, it includes a mounting frame 1, an arc-shaped base 2, a sliding rail 3, a sliding block 4, a mounting plate 5, a fixing frame 6, a motor 7, a heat sink 8, a first bearing 9, a first rotating shaft 10, a drill bit 11, The second bearing 12, the second rotating shaft 13, the rocking handle 14, the winding wheel 15, the first fixed pulley 16, the second fixed pulley 17, the first cable 18, the second cable 19 and the plunger 22, the mounting frame 1 left and right two The bottom of the wall is provided with an arc-shaped base 2, the inner middle of the left and right walls of the mounting frame 1 are inlaid with slide rails 3, the inner sides of the slide rails 3 on the left and right sides are slidably connected with sliders 4, and the inner ends of the sliders 4 on both sides are connected There is a mounting plate 5, the top center of the mounting plate 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com