Secondary cooling device used in continuous casting process

A technology of secondary cooling and continuous casting, applied in the field of secondary cooling devices, can solve the problems of hard to ensure uniformity, square billet, affecting normal production, etc.

Inactive Publication Date: 2010-08-25

PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The lateral unevenness of the secondary cooling (inconsistent cooling on all sides of the slab) may lead to defects such as slab deviation and square billet falling off, which will affect normal production

The uniformity of secondary cooling is so important, but due to various reasons, it is difficult to guarantee the uniformity

In the prior art, although the difference in cooling intensity between cooling sections can be realized by controlling the cooling water flow rate, for the same cooling section, the flow rate between each row of nozzles cannot be controlled separately

Therefore, the difference in cooling intensity is not reflected. If the nozzles in the first few rows of the section are arranged at equal intervals, insufficient cooling may occur, and the nozzles in the latter rows may be overcooled, which does not conform to the principle of uniform cooling.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

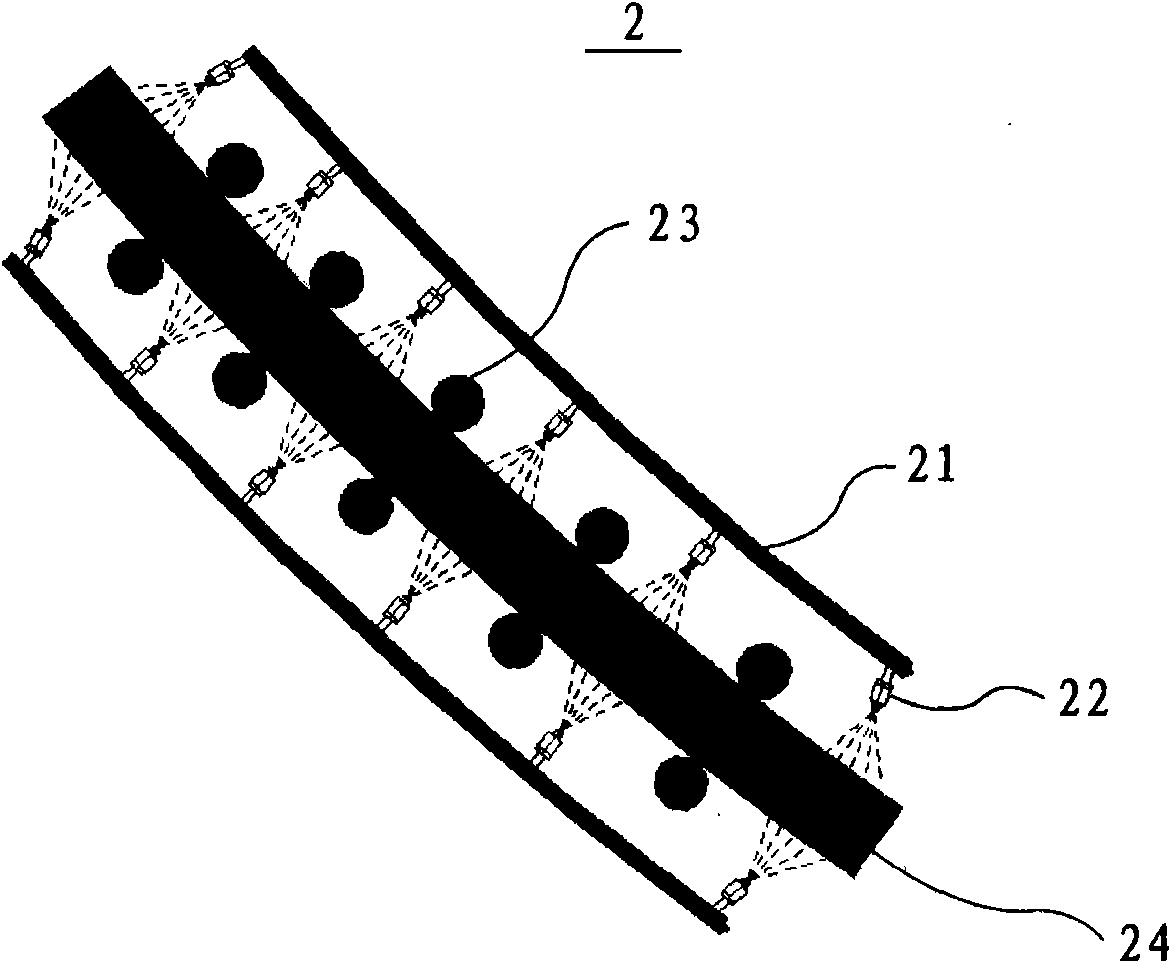

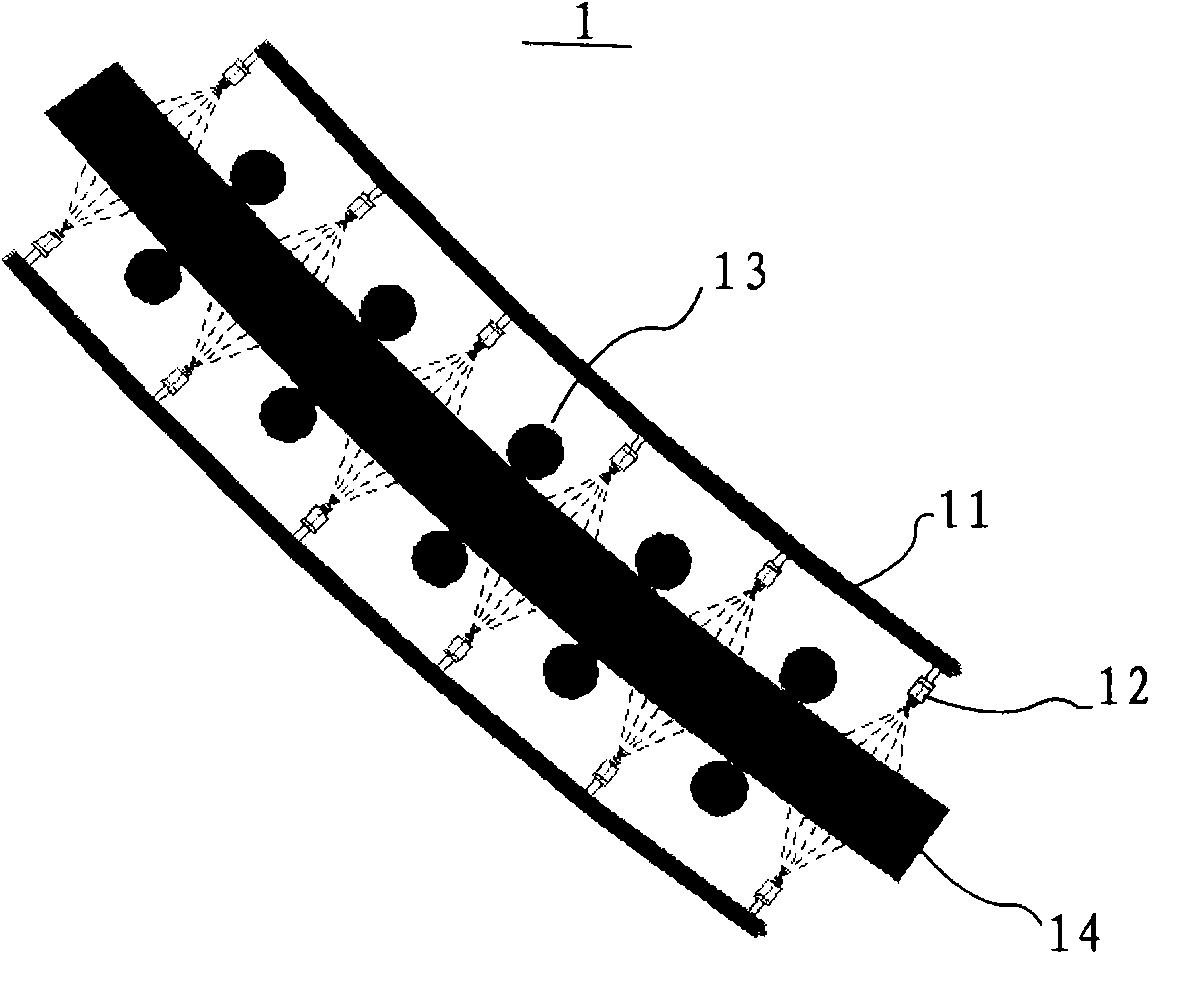

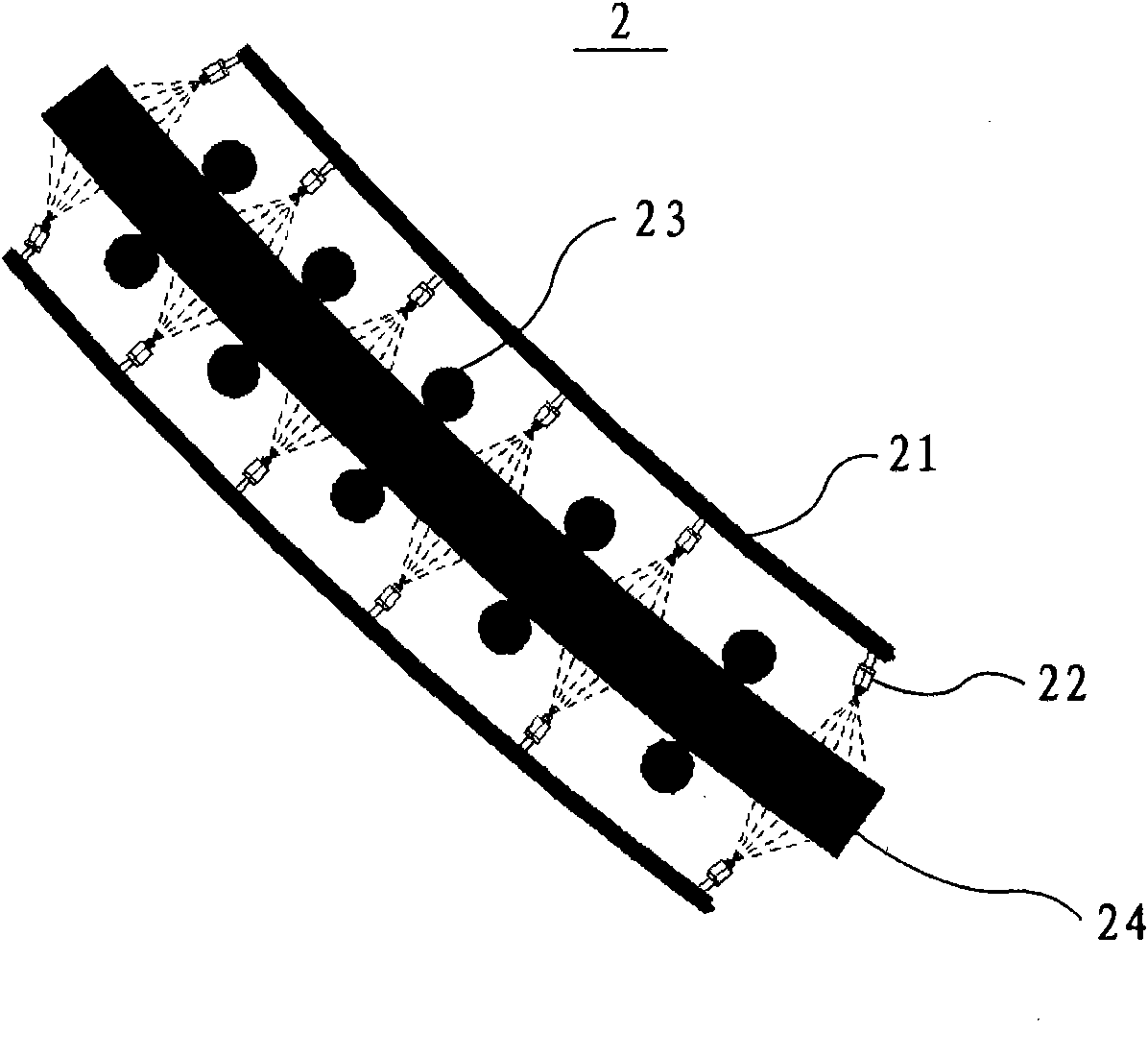

The invention discloses a secondary cooling device used in continuous casting process, comprising a plurality of cooling sections, wherein each cooling section comprises a cooling water pipe and a nozzle connected to the cooling water pipe, the distances between the nozzles in the cooling sections are different, the nozzles at both ends of each cooling section are obliquely arranged to a transition area, wherein the transition area is between two adjacent cooling sections. The secondary cooling device on the basis of the invention can simultaneously avoid the problems of insufficient cooling intensity of the front parts of the cooling sections, supercooling of the back parts of the cooling sections and insufficient cooling of the transition areas.

Description

Secondary cooling device used in continuous casting process technical field The present invention relates to a secondary cooling device used in the continuous casting process, more specifically, the present invention relates to a secondary cooling device used in the continuous casting process that can improve the uniformity of the secondary cooling and improve the quality of the continuous casting slab secondary cooling device. Background technique Continuous casting technology has entered the stage of industrial application since the early 1950s, and has made great progress in the past 60 years. The output and quality of continuous casting slabs have been greatly improved, and the process level and process equipment have also improved A breakthrough has been made. Secondary cooling is an important link in the continuous casting process, which directly affects the internal cracks, surface cracks and solidification structure of the slab. Good secondary cooling has a direc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D11/124

Inventor 黎建全陈登福李桂军张健朱义才蒋军廖水碧解明科

Owner PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com