Porous structure layer for heat pipe and its making process

A porous structure and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, instruments, etc., can solve problems such as dry burning, damage to heat pipes, and inability to replenish evaporated liquid quickly, achieving low return flow resistance, improved performance, and high The effect of capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

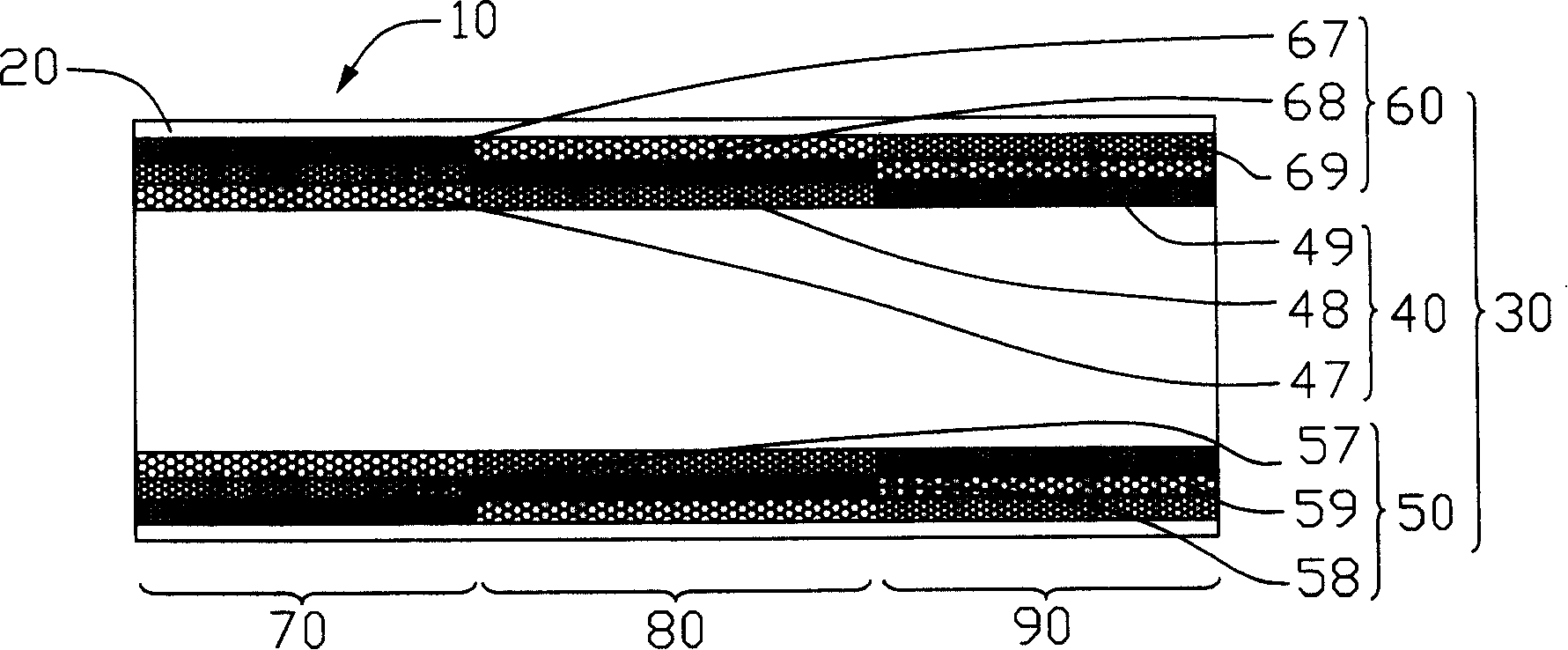

[0019] Such as figure 1 As shown, the heat pipe 10 of the present invention includes a pipe body 20 , a porous structure layer 30 in close contact with the inner wall of the pipe body 20 and a working liquid filled in the pipe body 20 .

[0020] The tube body 20 is made of a metal material with good thermal conductivity, such as copper, etc. The cross section of the tube body 20 is circular. It can be understood that the cross section of the tube body 20 can also be in other shapes, such as square, polygonal, oval etc., the working liquid filled in the pipe body 20 generally adopts a liquid with a low boiling point, such as water, alcohol, etc.

[0021] One end of the heat pipe 10 is the evaporation end 70 of the heat pipe 10, and the other end is the condensation end 90 of the heat pipe 10. Between the condensation end 90 and the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com