Temperature-uniforming plate

A technology of vapor chamber and bottom plate, which is used in lighting and heating equipment, indirect heat exchangers, cooling/ventilation/heating renovation, etc. Welding and assembly problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

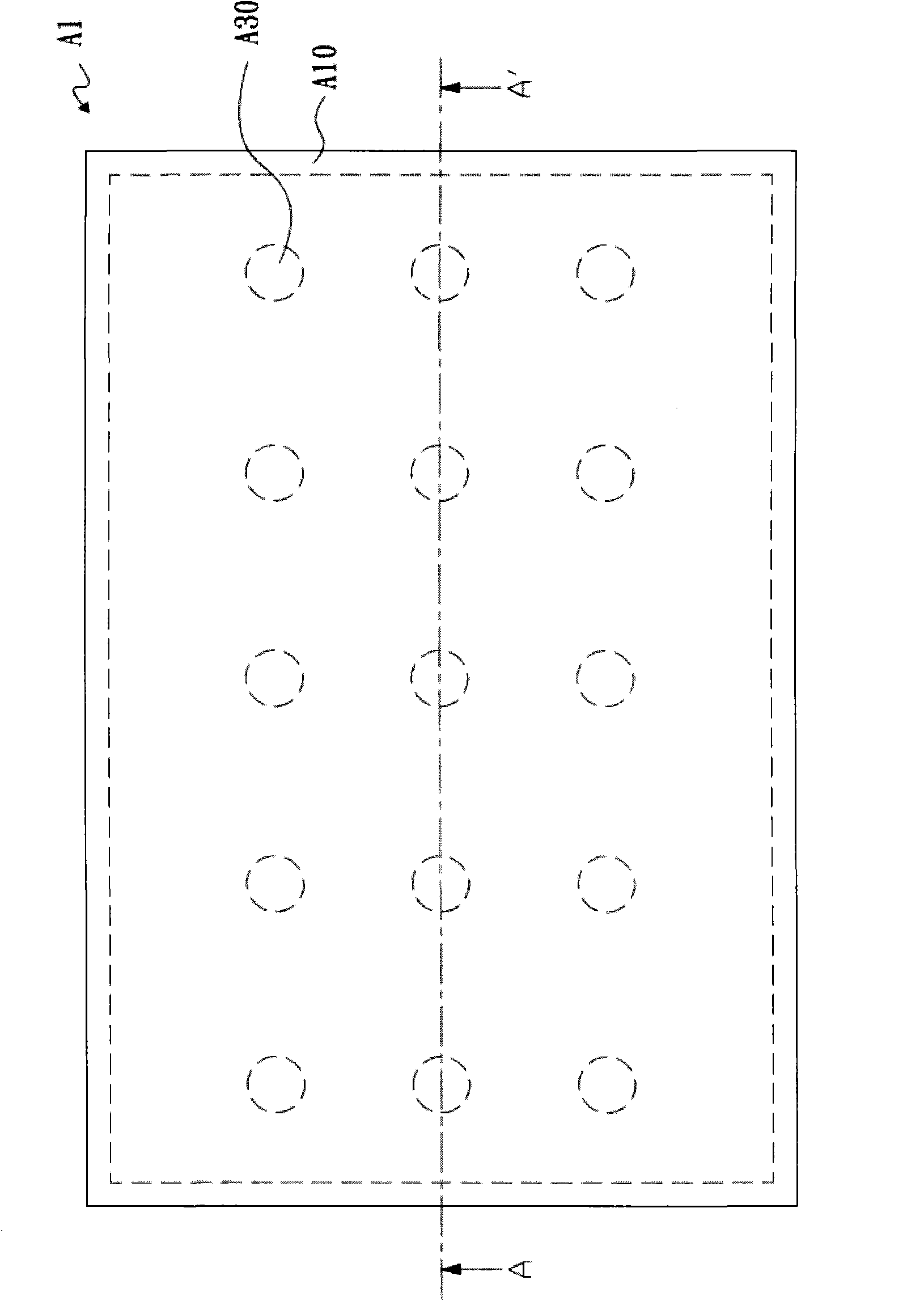

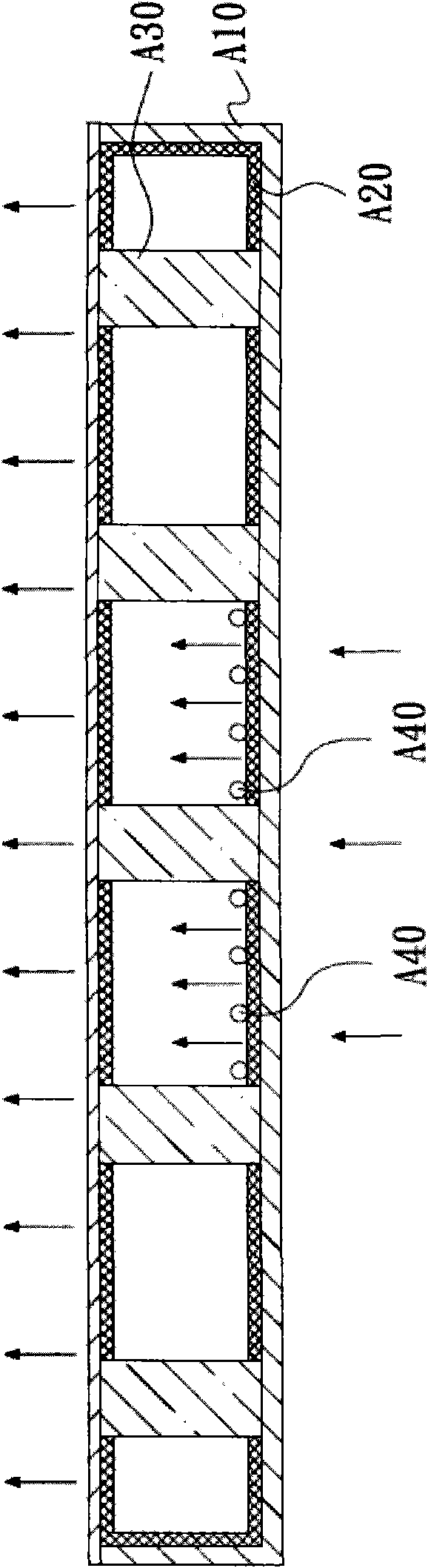

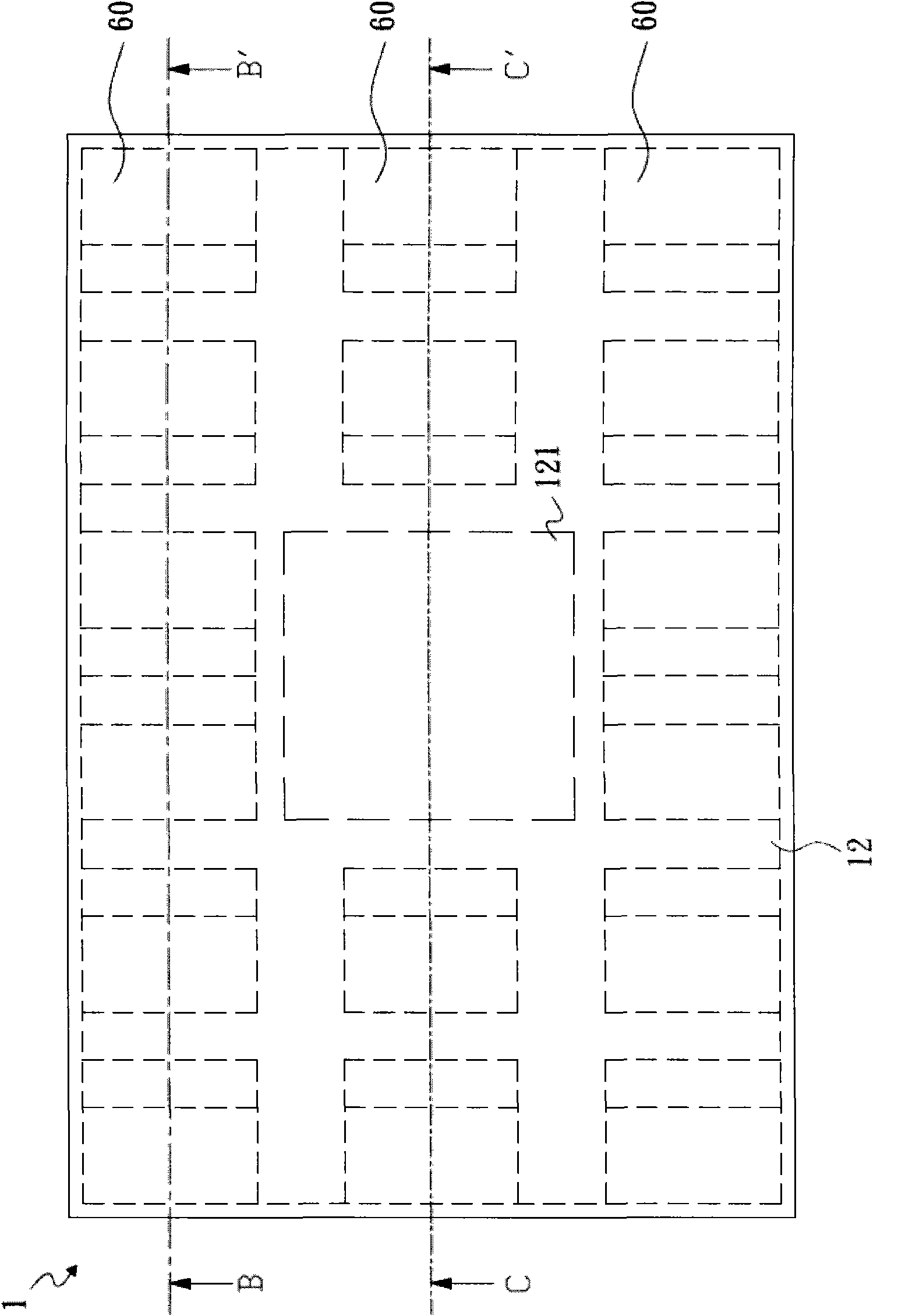

[0021] see image 3 , Figure 4 and Figure 5 As shown, it is the vapor chamber disclosed in the first embodiment of the present invention. The vapor chamber 1 includes a vacuum cavity 10 , a working fluid 20 , an upper capillary structure 30 , a lower capillary structure 40 , and a plurality of support columns 60 .

[0022] The vacuum chamber 10 has a roughly rectangular shape and is composed of an upper cover 11 and a bottom plate 12 . The sides of the bottom plate 12 are bent and welded to the upper cover 11 at high temperature to form a closed space between the upper cover 11 and the bottom plate 12 . In addition, the bottom plate 12 is provided with a heating area 121 at the center, and the upper cover 11 is provided with a cooling area 111 corresponding to the heating area 121 .

[0023] The working fluid 20 is located in the vacuum cavity 10 , and it is a fluid with two phase changes, preferably water, but the invention is not limited thereto.

[0024] The upper capi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com