Gas-liquid separation device for enhancing self-absorption of self-absorption type multistage centrifugal pump

A technology of a gas-liquid separation device and a self-priming centrifugal pump, which is applied in the field of fluid machinery, can solve problems such as poor gas-liquid separation effect, poor self-priming stability, and slow self-priming speed, and achieve small fluid kinetic energy loss, lifting pressure, and The effect of increased gas carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and example.

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

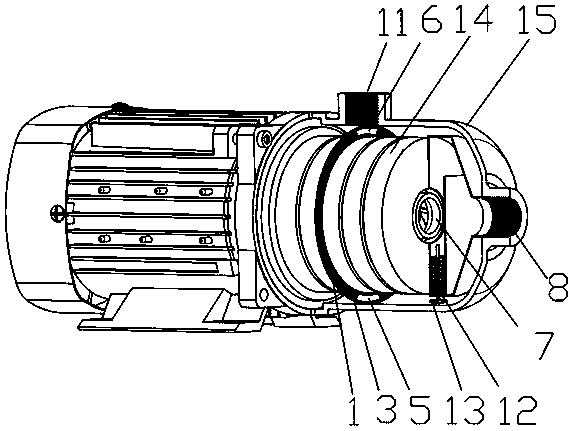

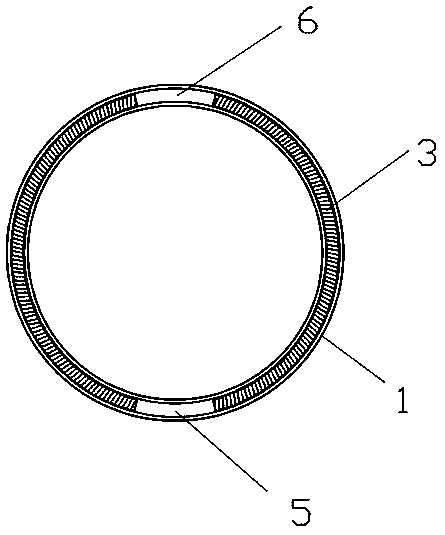

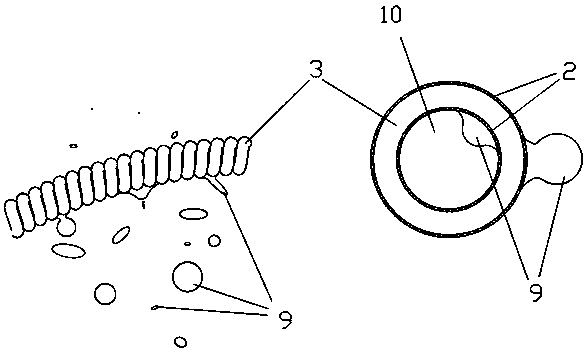

[0030] Such as figure 1 As shown, the present invention is a device for promoting gas-liquid separation in a self-priming centrifugal pump installed between the pump casing cavity and the pump casing. The device is an annular gas-liquid separation device that enhances gas-liquid separation and flow uniformity in the pump casing cavity . The gas-liquid separation device is composed of a ring bracket 1 supporting the ring-shaped gas-liquid separation device and a ring spring 3 evenly coated with a hydrophobic coating 2. The ring spring 3 is closely attached to the ring bracket 1 and installed at the outlet 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com