Flat type heat-pipe

A flat, heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems such as dry burning of electronic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

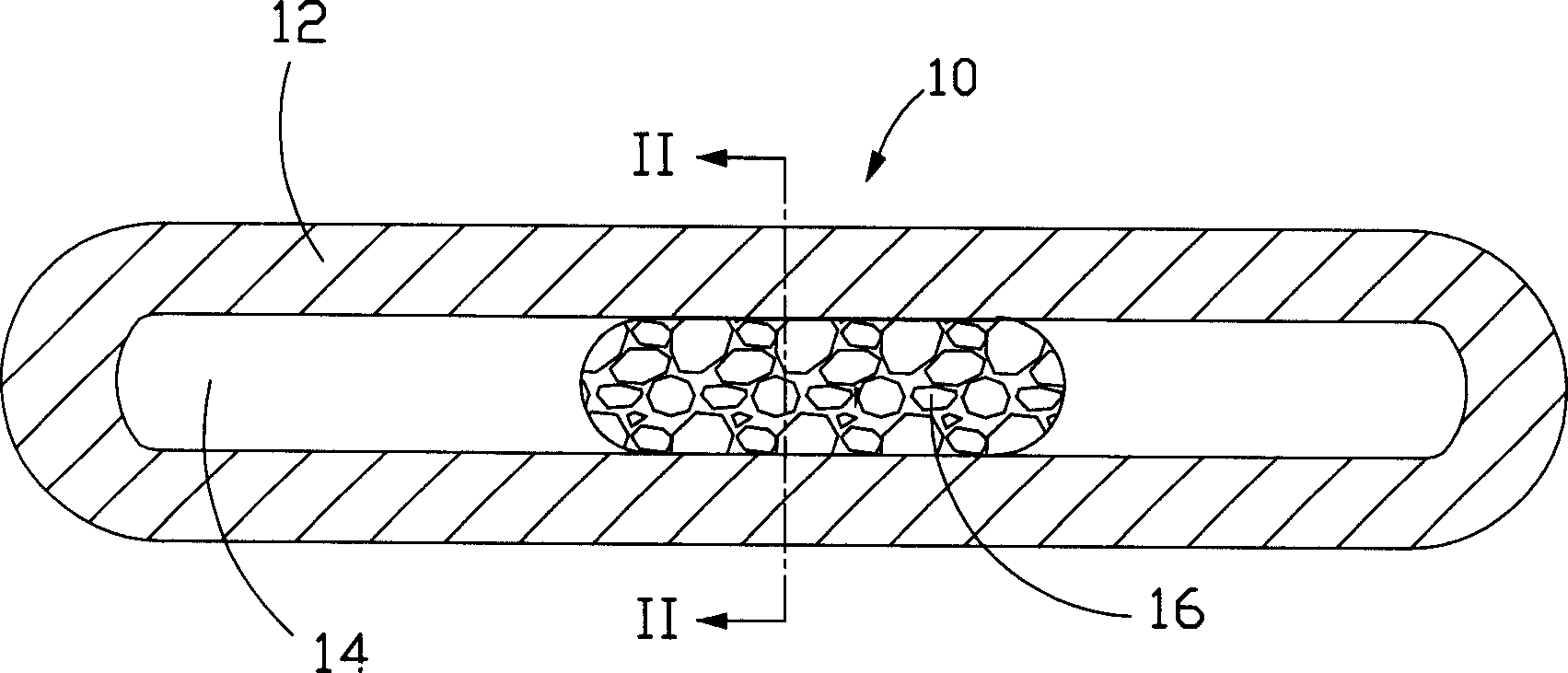

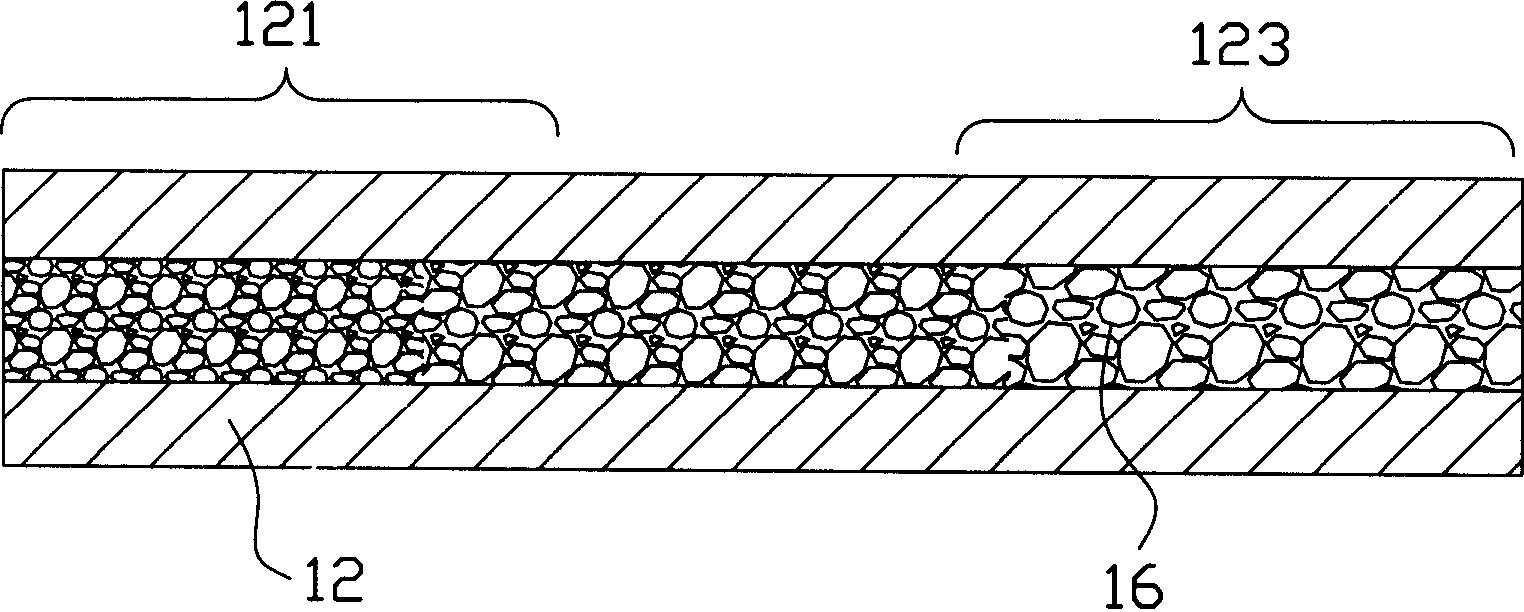

[0015] Such as Figure 1 to Figure 2 Disclosed as the first embodiment of the flat heat pipe of the present invention, the heat pipe 10 is flat and includes a casing 12, and a cavity 14 is formed in the casing 12, and the cavity 14 is filled with an appropriate amount of working liquid (not shown in the figure), the housing 12 can be made of materials with good thermal conductivity such as copper, aluminum, etc., one end forms the evaporation section 121, and the other end forms the condensation section 123, please refer to figure 2 shown. A capillary structure 16 is disposed in the center of the cavity 14 , and the spaces on the left and right sides of the cavity 14 without the capillary structure 16 form air passages for steam circulation. The capillary structure 16 is metal foam (foam metal), which is a three-dimensional space mesh porous structure sandwiched between the upper and lower inner walls of the housing 12, and extends from the condensation section 123 to the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com