Centrifugal fan

A centrifugal fan and shaft center technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of large working noise, large working pressure difference of centrifugal fan, air pressure leakage, etc., so as to improve work efficiency and work quality , Increase the air volume and air pressure, and increase the effect of return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

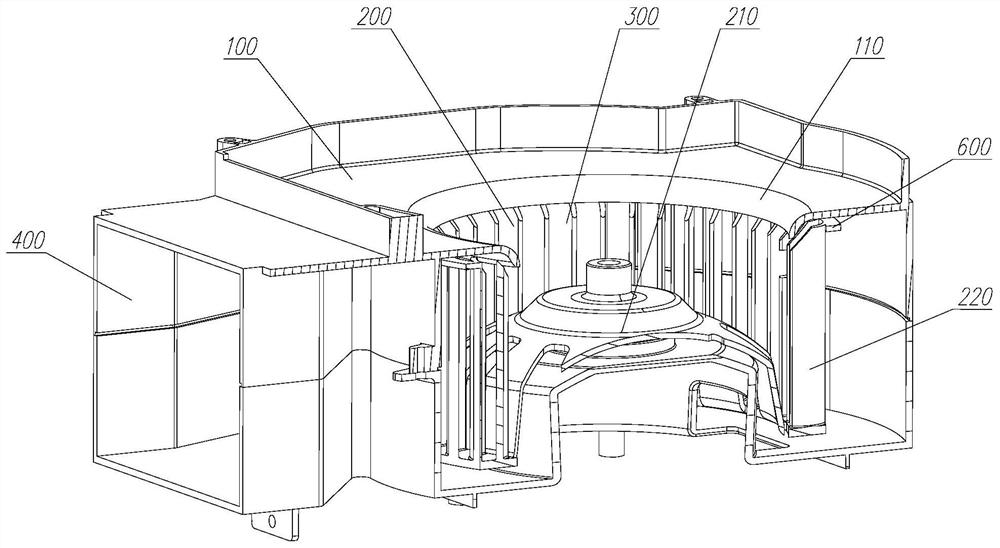

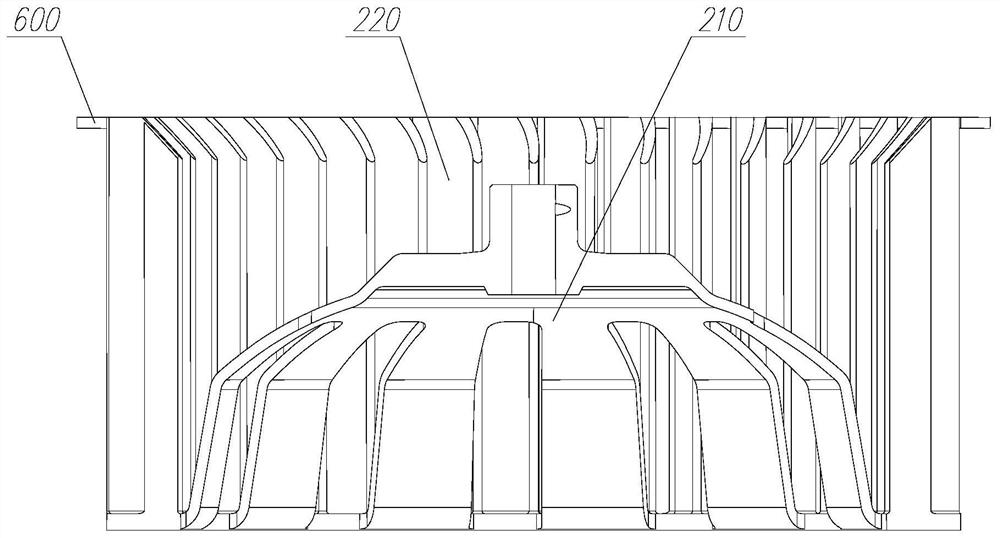

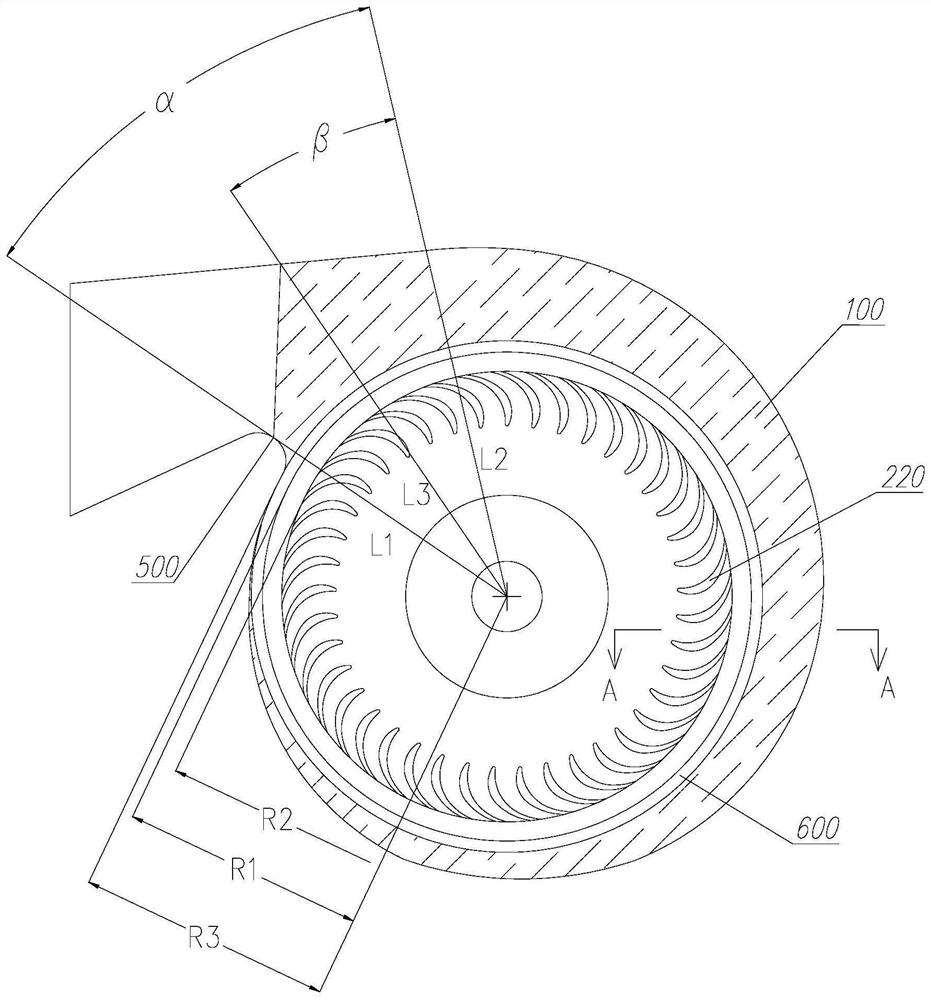

[0026]The impeller blade radius of the centrifugal fan is 75mm, the impeller height is 80mm, the number of blades is 41, and the thickness of the ring fixed head is H 1 2mm, the gap H between the axial direction of the impeller and the volute 3 The distance R between the inner wall of the volute in the area of the volute tongue at the narrowest part of the flow channel of the centrifugal fan and the center of the impeller axis is 3.5mm 3 is 85mm. The radius of the annular fixing strip in the conventional centrifugal fan is 77mm, and the radius R of the annular fixing strip is set in this embodiment 1 is 82mm, and set the height H of the boss 2 is 60mm, and the inclination angle of the bevel at the end of the boss is 30°. Comparing the centrifugal fan with the conventional structure, the air volume of the centrifugal fan in this embodiment is increased by 3%, and the air output efficiency is increased by 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com