Composite liquid sucking core of toothed heat pipe and manufacturing method thereof

A manufacturing method and a liquid absorbing core technology are applied in the field of heat pipes for heat transfer, which can solve the problems of low backflow resistance, low thermal resistance, and large capillary pressure, and achieve the effects of reducing backflow resistance, enhancing evaporation and condensation, and improving capillary force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for manufacturing a composite liquid-absorbing core of a toothed heat pipe, comprising the following steps and process conditions:

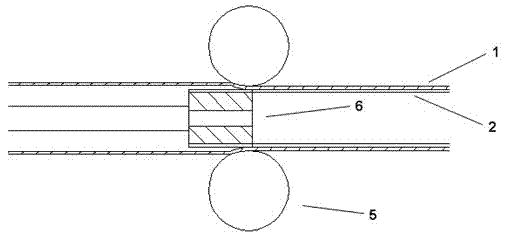

[0039] (1) Processing of toothed heat pipes: Using the high-pressure oil layer in the closed cavity, the spinning ball is used to spin the outer wall of the copper tube to transfer the spinning pressure. Under the action of extrusion force, plastic deformation occurs locally, and micro grooves are processed.

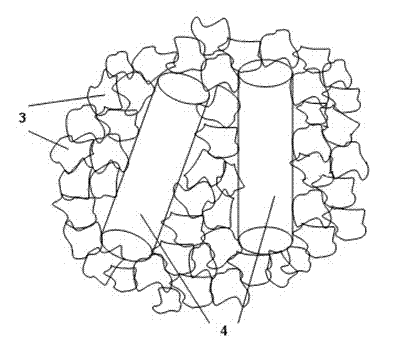

[0040] (2) Filler: Use copper powder particles with a particle size of 100-140 mesh. The copper powder particles are spherical copper powder and irregular copper powder, with irregular copper powder particles being the majority. Take copper fibers with a diameter of 150 μm and a length of 2 mm, and the mass ratio of copper powder particles to copper fibers is 8:1; put a mandrel in a copper round tube to form a ring-shaped liquid-absorbing core to fill the space, and fill in a certain quality of copper powder A mixture of pa...

Embodiment 2

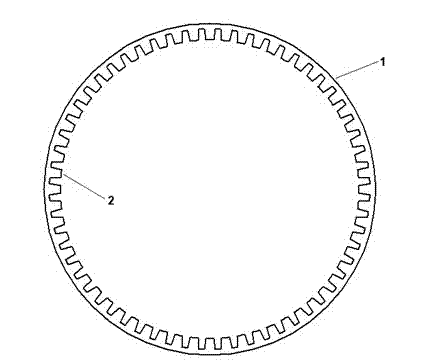

[0046] Compared with Example 1, the difference is that the number of groove teeth on the wall of the copper circular tube is 55, the tooth height is 0.25mm, and the tooth width is 0.17mm. The particle size of the copper powder is 120 mesh to 140 mesh, and the single length of the copper fiber is 2mm. The mass of the two is mixed at a ratio of 10:1 to form a sintered material. The heat preservation and sintering temperature is 940° C., and the heat preservation is 90 minutes to obtain a composite liquid-absorbing core. The heat transfer effect is basically the same as in Example 1.

Embodiment 3

[0048] Compared with Example 1, the difference is that the number of groove teeth on the wall of the copper circular tube is 60, the tooth height is 0.25mm, and the tooth width is 0.15mm. The particle size of the copper powder is 80 mesh to 100 mesh, and the single length of the copper fiber is 2mm. The mass of the two is mixed at a ratio of 6:1 to form a sintered material. The heat preservation and sintering temperature is 970° C., and the heat preservation is 90 minutes to obtain a composite liquid-absorbing core. The heat transfer effect is basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com