Ultra-thin heat pipe

A technology of ultra-thin heat pipes and pipe bodies, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., and can solve the problem of poor permeability, limited porosity and heat transfer efficiency, and axial heat transfer of heat pipes with sintered powder cores. The capacity is small and other problems, to achieve the effect of enhancing axial heat transfer capacity, saving materials, and enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

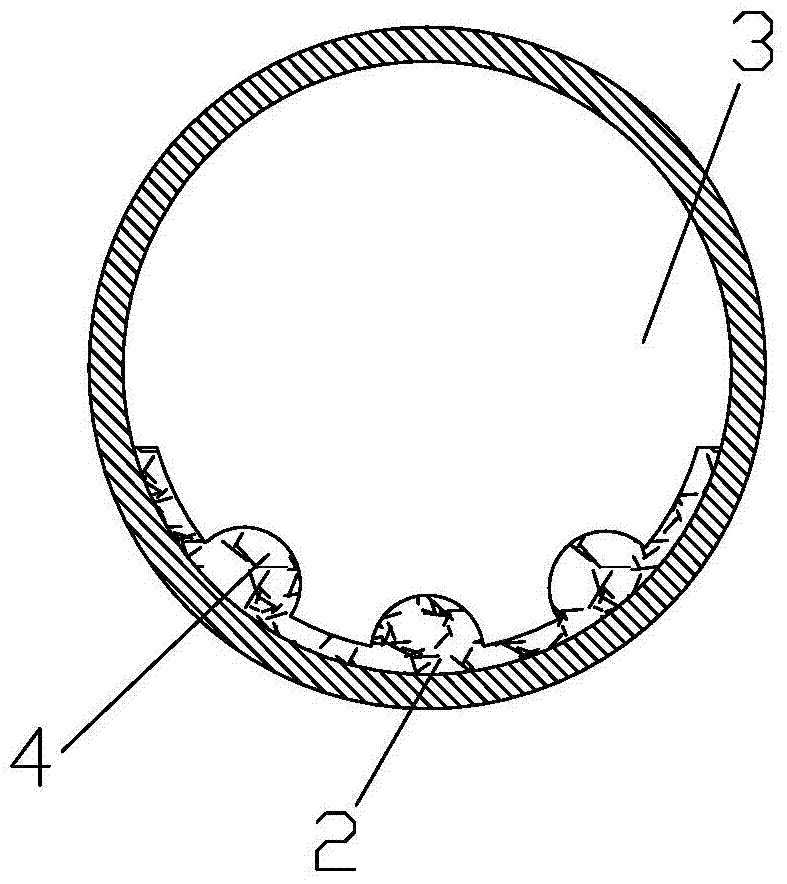

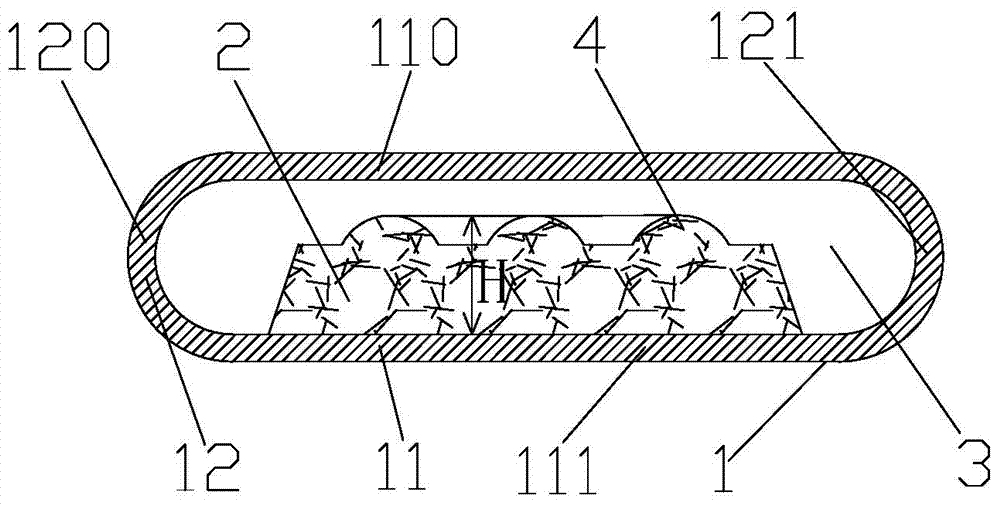

[0038] like figure 1 and figure 2 As shown, an ultra-thin heat pipe provided in this embodiment includes a pipe body 1 , and the pipe body 1 includes a middle side wall 11 and an end side wall 12 connected to the middle side wall 11 . Wherein, the tube body 1 is a copper tube with an inner diameter of 6 mm or 8 mm and a wall thickness of 0.2 mm, or an aluminum tube, a stainless steel tube or a titanium tube of the above specifications. The middle side wall 11 is a straight pipe wall, and the cross section of the end side wall 12 is arc-shaped, preferably semi-circular.

[0039] In this embodiment, the middle sidewall 11 includes a first middle sidewall 110 and a second middle sidewall 111 , and the end sidewall 12 includes a first end sidewall 120 and a second end sidewall 121 . A first end of the first middle sidewall 110 is connected to a first end of the first end sidewall 120 , and a second end of the first middle sidewall 110 is connected to a first end of the second e...

Embodiment 2

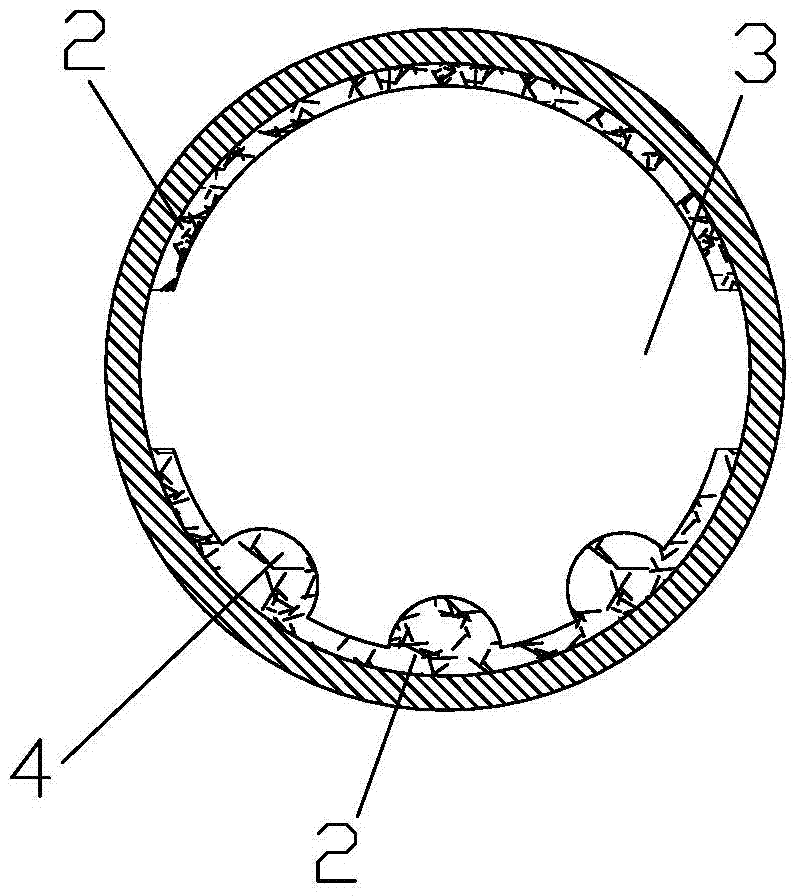

[0044] like image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the inner wall of the first middle side wall 110 and the inner wall of the second middle side wall 111 are provided with a metal powder sintered part 2, and both A steam channel 3 is formed between the first metal powder sintered part 2 and the middle side wall 11 and the end side wall 12, wherein a protrusion 4 is provided on the side of the metal powder sintered part 2 away from the second middle side wall 111, although the steam The space of the channel is smaller than the space of the steam channel in Embodiment 1, but the flow rate of the steam and the heat transfer efficiency of the heat pipe are improved, and the thermal conductivity is good, so it is more suitable as a heat sink for micro-equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com