Sintering type heat pipe and manufacturing method thereof

A manufacturing method and sintering technology, applied in the field of heat dissipation, can solve problems such as inability to quickly replenish, decrease in liquid velocity, damage to heat pipes, etc., and achieve the effects of improving heat pipe performance, low reflux resistance, and large capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

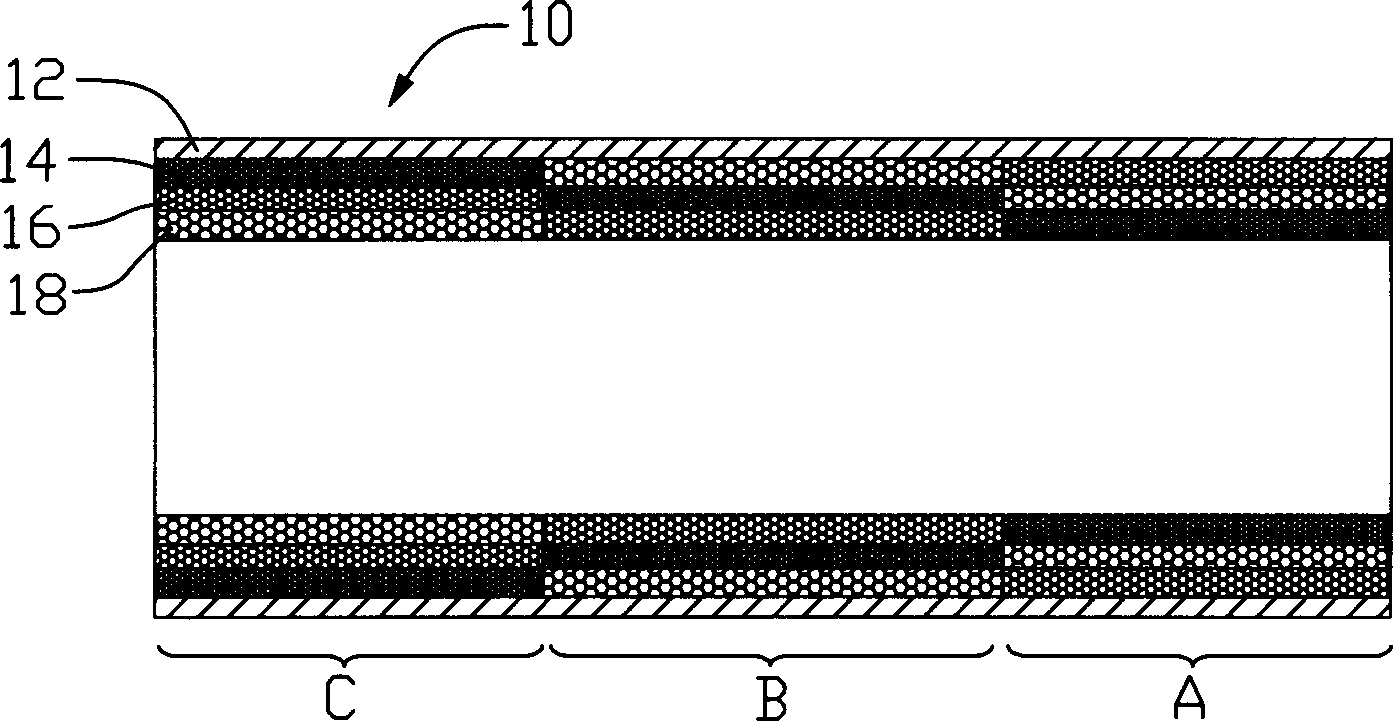

[0014] like figure 1 As shown, the heat pipe 10 of the present invention includes a pipe body 12 and a porous capillary structure disposed on the inner wall of the pipe body 12 . Wherein, the pipe body 12 is made of a metal material with good thermal conductivity such as copper, and the cross section of the pipe body 12 shown in the figure is circular. It can be understood that the cross section of the pipe body 12 can also be in other shapes, such as Square, polygonal, oval, etc. In addition, the tube body 12 is also filled with a working liquid (not shown in the figure), and the working liquid generally adopts a liquid with a low boiling point, such as water, alcohol, and the like.

[0015] One end of the heat pipe 10 forms an evaporating section A, and the other end forms a condensing section C, and an insulating section B can be arranged between the two sections according to application requirements. The liquid is used to evaporate the liquid. The insulation section B is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com