Ultrathin heat pipe and manufacturing method thereof

A technology of ultra-thin heat pipes and manufacturing methods, which is applied in the field of heat conduction, and can solve the problems of wire mesh inner core falling off, too high requirements for metal mesh, unfavorable heat dissipation, etc., and achieve the effects of not easy to disperse, convenient operation of process steps, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

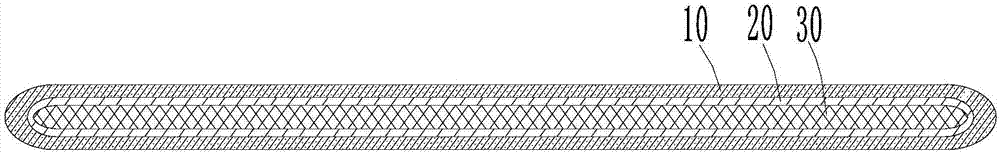

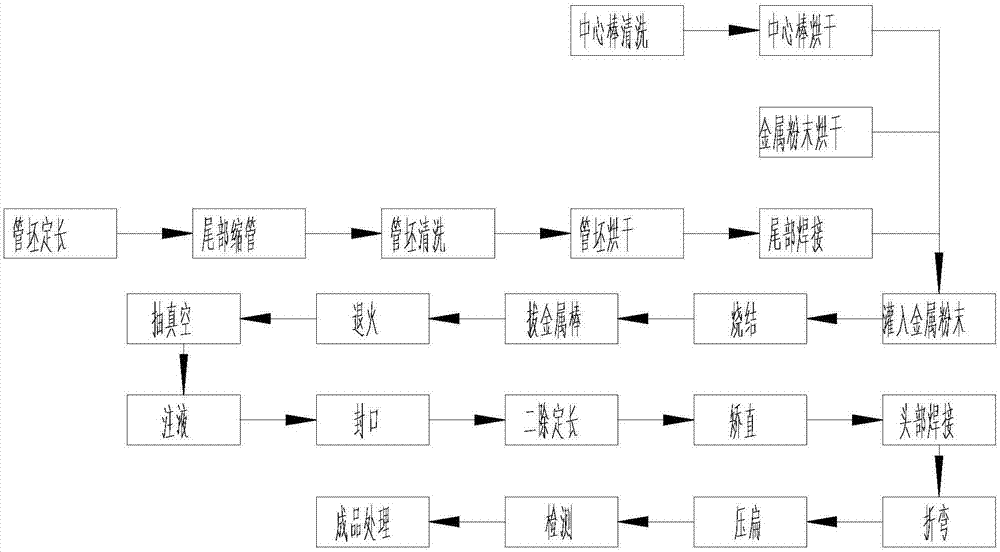

[0094] refer to Figure 1-2 , an ultra-thin heat pipe, comprising a metal pipe body 10, a liquid-absorbing core 20 and a working medium 30;

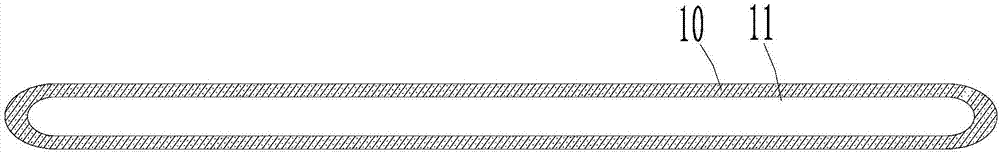

[0095] The wall thickness of the metal pipe body 10 is 0.10 mm, and its tail and head are sealed ends. The metal pipe body is a flat metal pipe body with an airtight inner cavity 11; The necking part of the tail is welded to form the tail sealing end, and the head of the metal pipe body is welded to form the head sealing end.

[0096] The liquid-absorbing core 20 is arranged in the sealed inner cavity 11 of the metal pipe body 10, and the liquid-absorbing core 20 is a metal powder sintered capillary layer with uniform thickness formed by bonding the metal powder to the inner wall of the metal pipe body through high-temperature sintering;

[0097] The working medium 30 is filled in the sealed inner chamber 11 of the metal pipe body 10 . During the working process, the working medium can penetrate into the metal powder sintered capillary l...

Embodiment 2

[0126] The feature of this embodiment is that the metal powder sintered capillary layer is evenly distributed on the entire inner wall of the metal pipe body, and the thickness of the metal powder sintered capillary layer is 0.05 mm. The wall thickness of the metal pipe body is 0.03 mm. The overall thickness of the ultra-thin heat pipe is 0.20 mm. The metal powder is aluminum powder with a particle size of 200-300 mesh. The working medium is a mixed solvent of acetone and pure water in any ratio.

[0127] Others are the same as in Example 1.

Embodiment 3

[0129] The characteristics of this embodiment are: the metal powder sintered capillary layer is uniformly distributed on the entire inner wall of the metal pipe body, and the thickness of the metal powder sintered capillary layer is 0.10 mm. The wall thickness of the metal pipe body is 0.05 mm. The overall thickness of the ultra-thin heat pipe is 0.50mm. The metal powder is magnesium powder, and the particle size is 200-300 mesh. The working medium is a mixed solvent of ethanol and pure water in any ratio.

[0130] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com