Method for manufacturing miniature heat pipe by employing ultrathin foamed silver as wick

A technology of micro heat pipes and silver foam, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low porosity affecting liquid media, phase change cycle speed increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

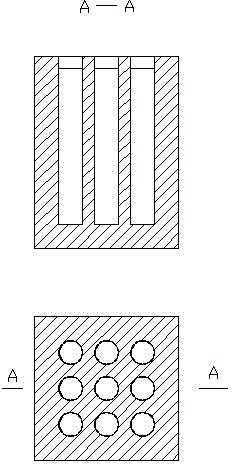

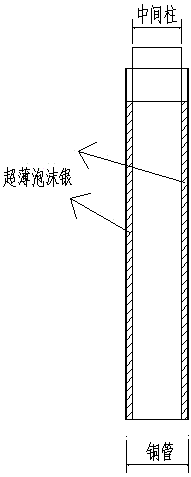

[0016] The following is the use of ultra-thin silver foam to prepare a micro heat pipe with an outer diameter of 8 mm and a liquid-absorbing core with a thickness of 0.4 mm and different porosity.

[0017] (1) A copper tube with an outer diameter of 8 mm and a wall thickness of 0.3 mm according to the selected pure copper tube (copper or oxygen-free copper);

[0018] (2) After cleaning and drying, the porous cordierite template was placed to ensure vertical positioning, and then stainless steel or alumina ceramic intermediate columns with a diameter of 6.6 mm were placed according to the positioning method;

[0019] (3) According to the design requirements, select a suitable size of ultra-thin silver foam with a thickness of 0.4 mm, and insert it into the pores of the copper tube together with the stainless steel or ceramic intermediate column after crimping;

[0020] (4) Transfer to the reduction furnace for high-temperature reduction and sintering. First, use nitrogen to was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com