A gradient aperture porous copper liquid-absorbing core for a loop heat pipe and its preparation method

A loop heat pipe and porous copper technology, applied in the field of heat transfer, can solve the problem of not considering steam bubbles, etc., and achieve the effect of good heat transfer effect, large capillary suction force, and uniform distribution of pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

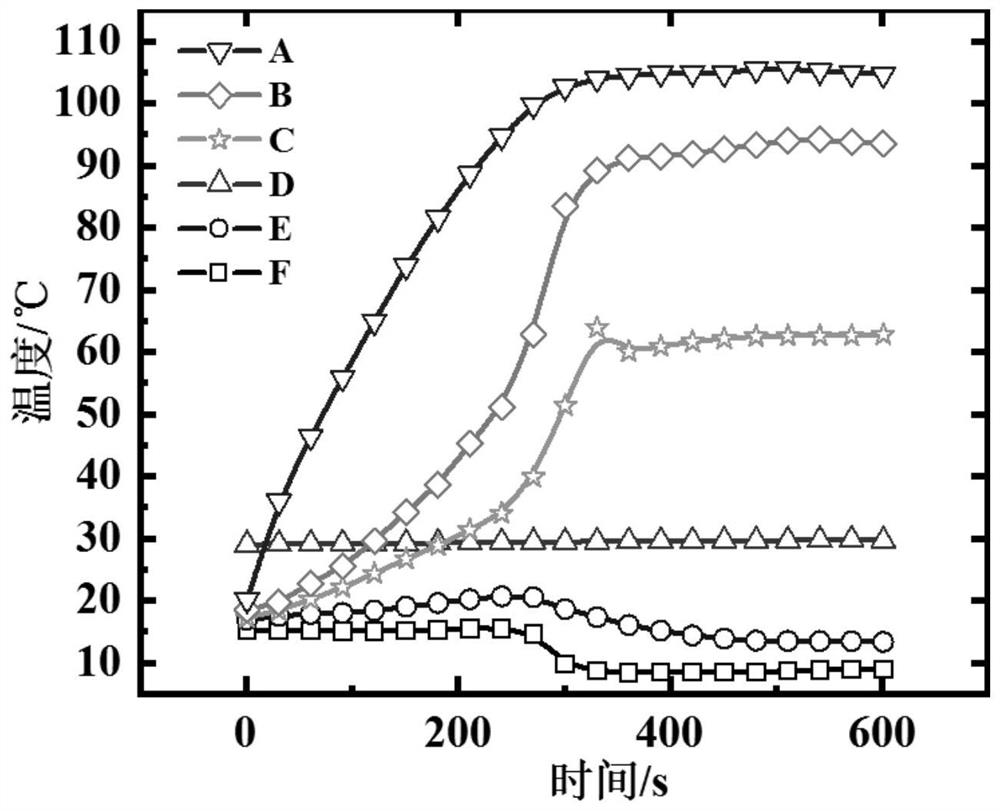

[0029] A method for preparing a gradient aperture porous copper liquid-absorbing core for a loop heat pipe, comprising the following steps:

[0030] Step 1: At room temperature, take an appropriate amount of analytically pure sodium chloride particles, grind them with a mortar and classify them through a series of screens to obtain a sodium chloride particle pore-forming agent with a particle size of 50-150 μm, and put it into 40 Dry in a vacuum oven for 24 hours to remove the moisture in it for later use;

[0031] Step 2: At room temperature, mix electrolytic copper powder with a particle size of 5 μm and sodium chloride particle pore-forming agents with a particle size of 50 and 150 μm at a volume ratio of 2:8, and use absolute ethanol as a ball milling medium. Put them together in a planetary ball mill, and ball mill and mix them for 30min at a speed of 150rpm to obtain a mixture C of copper powder and sodium chloride particles of different particle sizes. 1 、C 4 ;

[00...

Embodiment 2

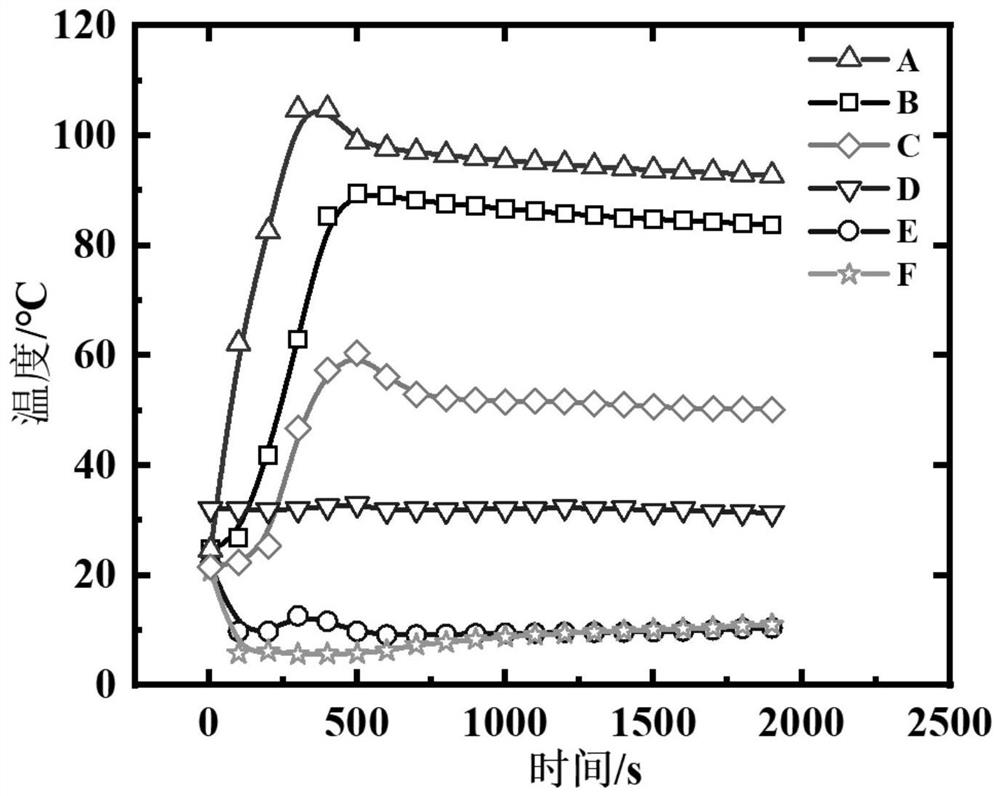

[0038] A method for preparing a gradient aperture porous copper liquid-absorbing core for a loop heat pipe, comprising the following steps:

[0039]Step 1: At room temperature, take an appropriate amount of analytically pure anhydrous sodium carbonate particles, grind them with a mortar and classify them through a series of sieves to obtain a pore-forming agent for sodium carbonate particles with a particle size of 50-150 μm, and put them in 40 Dry in a vacuum oven for 24 hours to remove the moisture in it for later use;

[0040] Step 2: At room temperature, mix electrolytic copper powder with a particle size of 5 μm and sodium carbonate particle pore-forming agents with a particle size of 50, 75, 106, and 150 μm in a volume ratio of 4:6, and use absolute ethanol as the Put the ball milling medium together into a planetary ball mill, and ball mill and mix them for 20 minutes at a speed of 150rpm to obtain a mixture of copper powder and sodium carbonate particles of different p...

Embodiment 3

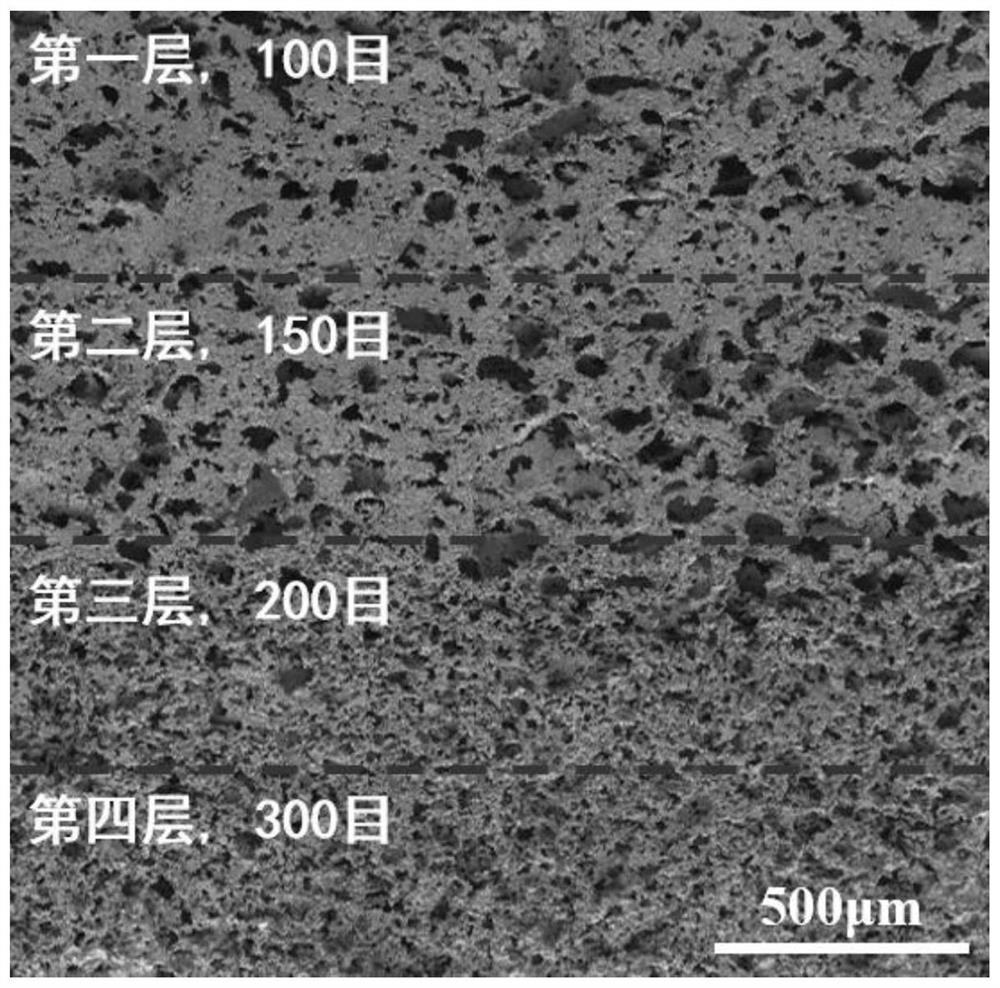

[0047] A method for preparing a gradient aperture porous copper liquid-absorbing core for a loop heat pipe, comprising the following steps:

[0048] Step 1: At room temperature, take an appropriate amount of analytically pure sodium chloride particles, grind them with a mortar and classify them through a series of screens to obtain a sodium chloride particle pore-forming agent with a particle size of 50-150 μm, and put it into 40 Dry in a vacuum oven for 24 hours to remove the moisture in it for later use;

[0049] Step 2: At room temperature, mix the electrolytic copper powder with a particle size of 5 μm and the sodium chloride particle pore-forming agent with a particle size of 50, 75, 106, and 150 μm in a volume ratio of 2:8, and mix them with absolute ethanol Put it into a planetary ball mill together as a ball milling medium, and ball mill and mix it for 30 minutes at a speed of 200rpm to obtain a mixture C of copper powder and sodium chloride particles of different part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com