A metal liquid-absorbent core with multi-aperture structure characteristics and its manufacturing method

A technology with structural features and a manufacturing method, which is applied in the field of metal liquid absorbent cores and its manufacturing, can solve the problems of not fundamentally solving the problems of controlling the liquid absorbent core structure, unstable capillary channels of the liquid absorbent core, and degraded heat exchange performance of heat pipes, etc. Achieve the effect of improving capillary suction characteristics and flow characteristics, excellent comprehensive performance, and improving technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

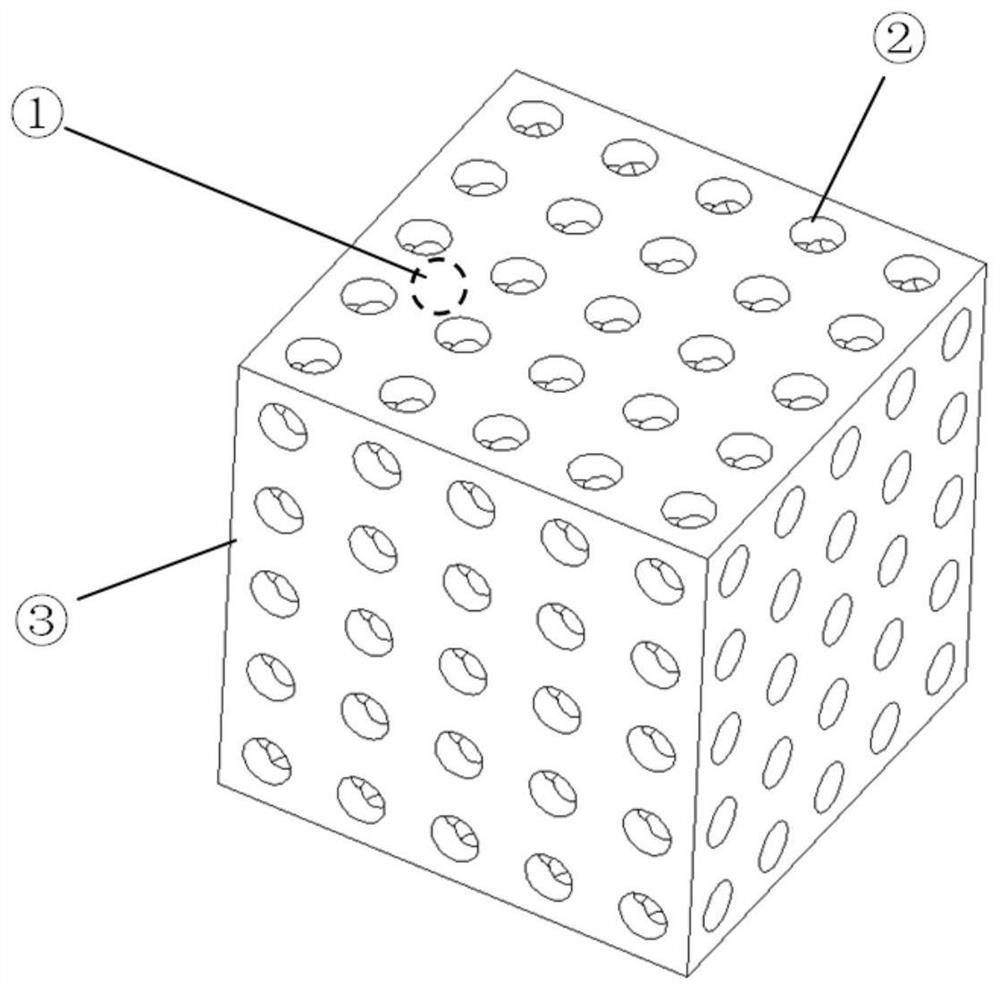

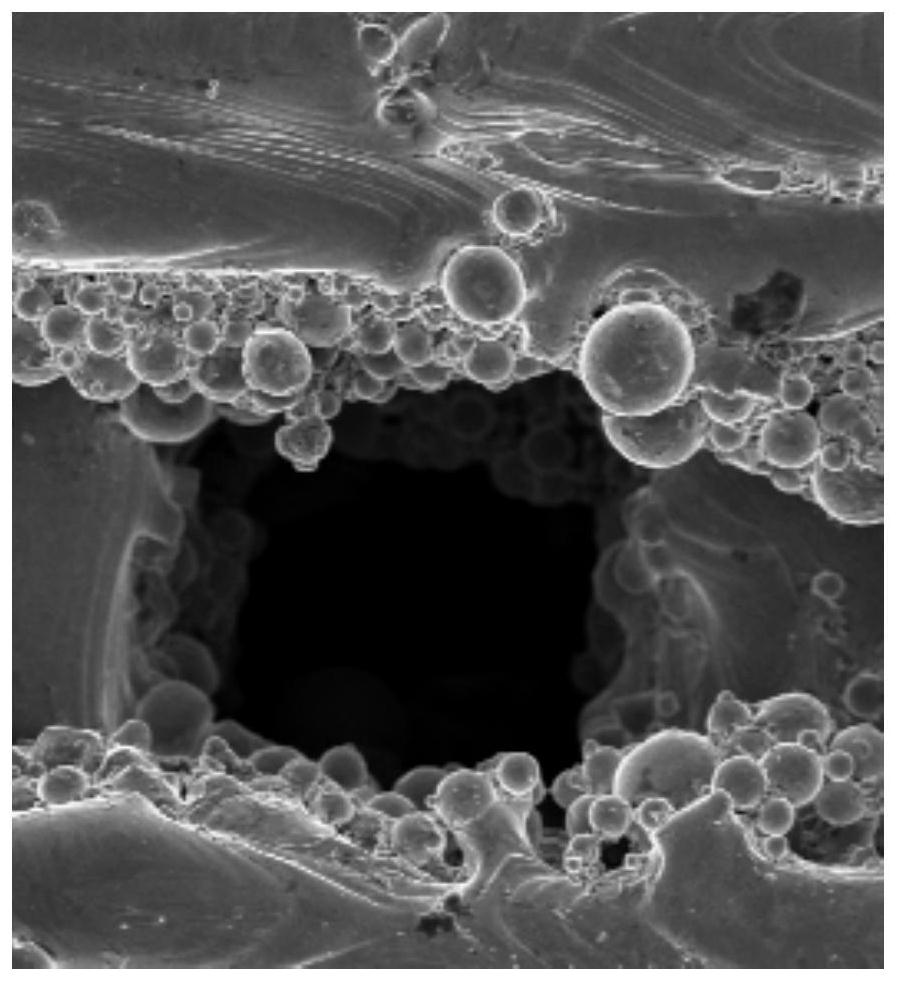

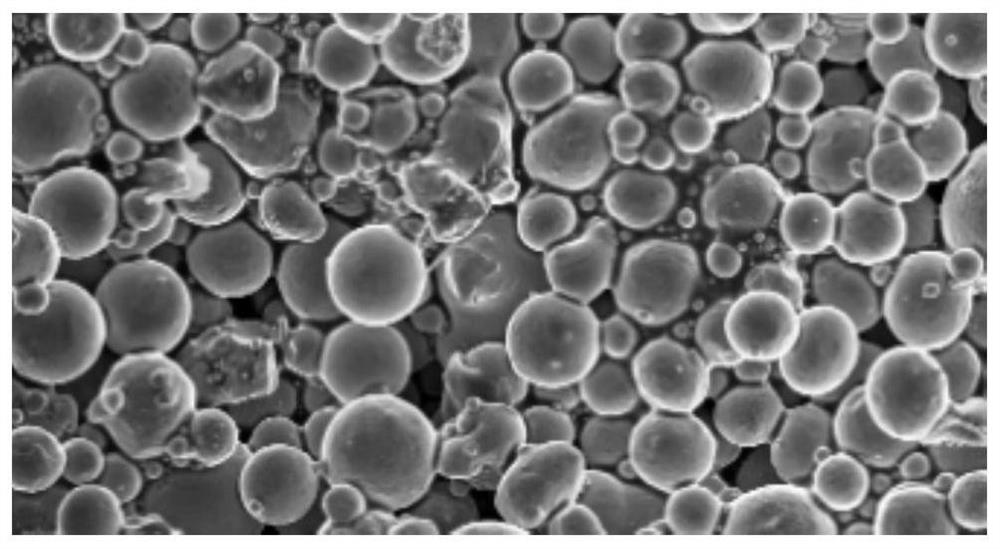

[0023] Such as Figure 1~4 As shown, a metal liquid-absorbing core with multi-aperture structure characteristics described in this embodiment includes a three-dimensional skeleton structure 3 formed by sintering metal powder, and macroporous structures 2 are arranged on the three-dimensional skeleton structure 3, and the macropores The structures 2 are connected to form a liquid flow channel, and the gaps between the metal powder particles form a microporous structure 1; the maximum pore diameter of the macroporous structure 2 does not exceed 100 μm; the maximum pore diameter of the microporous structure 1 does not exceed 0.5 μm.

[0024] In this embodiment, a method for manufacturing a metal liquid-ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com