Heat pipe

A heat pipe and capillary structure technology, applied in the field of heat pipes, can solve the problems of large capillary force, accelerated working fluid circulation, and large capillary force, etc., to increase the total contact surface area, increase heat transfer, and accelerate circulation. The effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

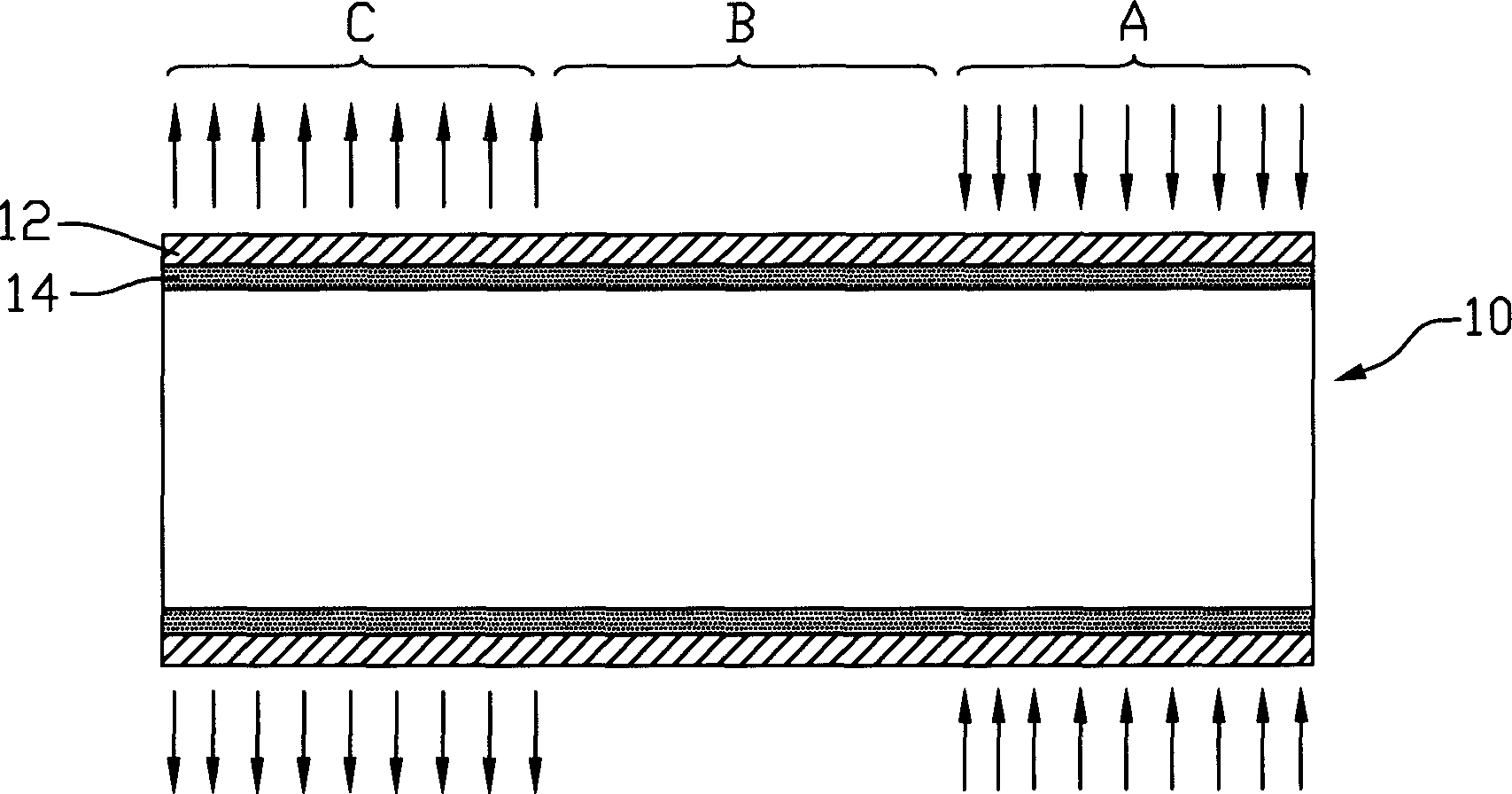

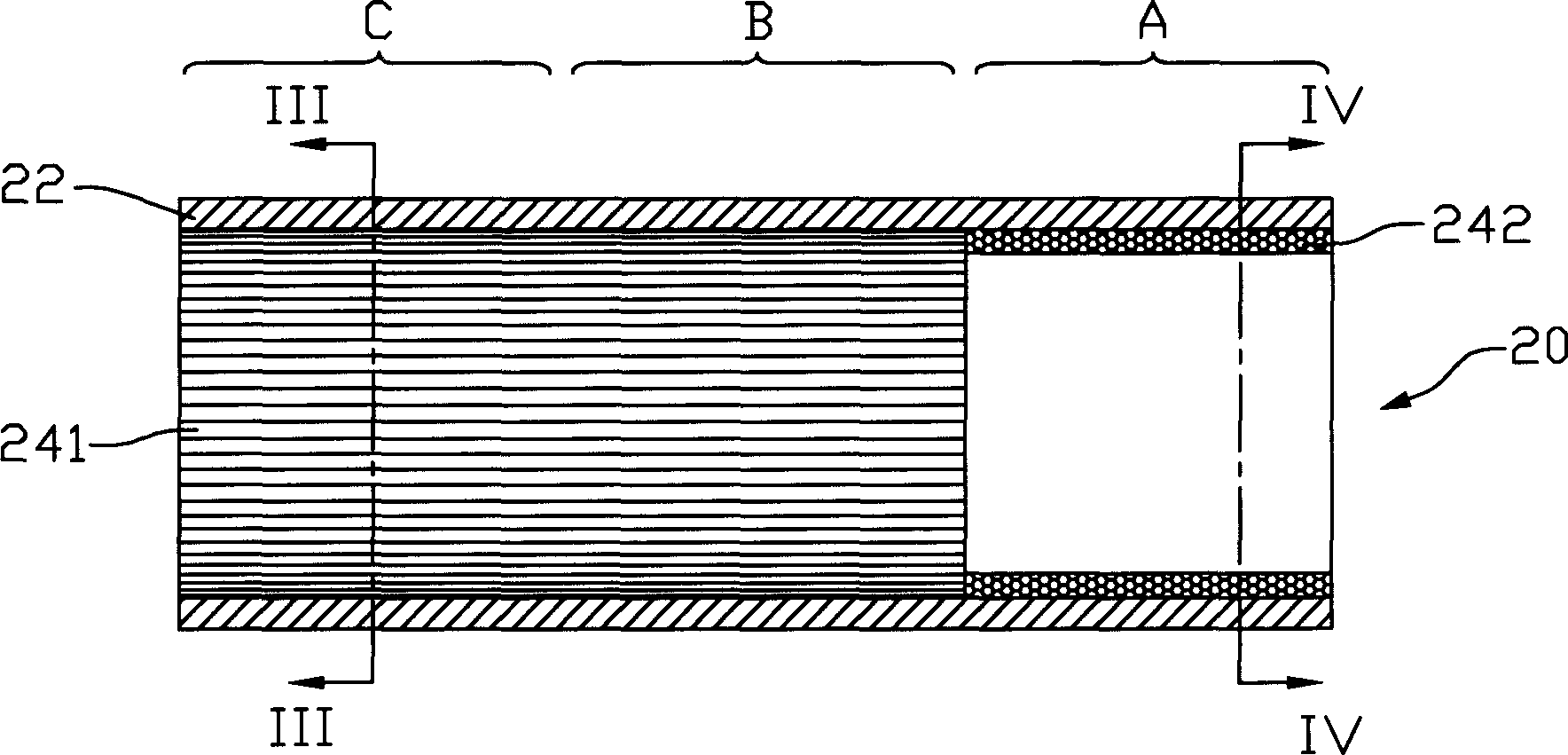

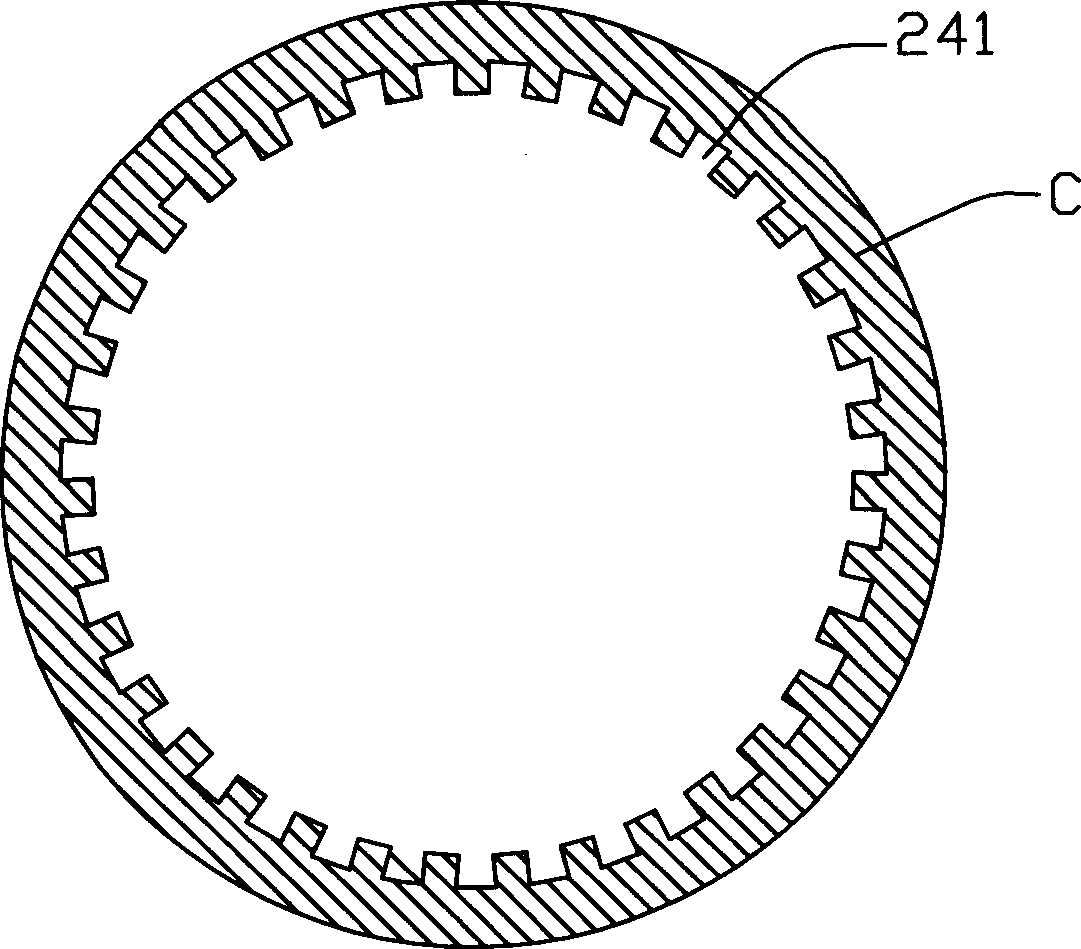

[0021] In view of the fact that a single type of capillary structure in the existing heat pipe cannot achieve the optimization of the heat transfer performance of the heat pipe, the present invention changes the capillary structure inside the heat pipe to a combination of different types of capillary structures, that is, the evaporation section and the condensation section of the heat pipe are provided with different Types of capillary structures, such as figure 2 Shown is a preferred embodiment of the heat pipe of the present invention. The heat pipe 20 sequentially forms a condensation section C, an adiabatic section B, and an evaporation section A along the length direction of the housing 22, wherein the condensing section C and the adiabatic section B adopt grooved capillary structure, such as image 3 As shown, it is formed by a number of small axial grooves 241; the evaporation section A adopts a sintered capillary structure, such as Figure 4A As shown, the sintered p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com