Hot plate of metal fiber felt liquid absorption cores

A technology of metal fiber felt and metal fiber, which is applied in the field of heat exchange equipment, can solve problems such as the structure of the liquid-absorbing core is easily damaged, the capillary pressure head is small, and the liquid reflux resistance is large, so as to increase the bonding strength and contact area, and achieve good capillary Force and permeability, the effect of small liquid return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

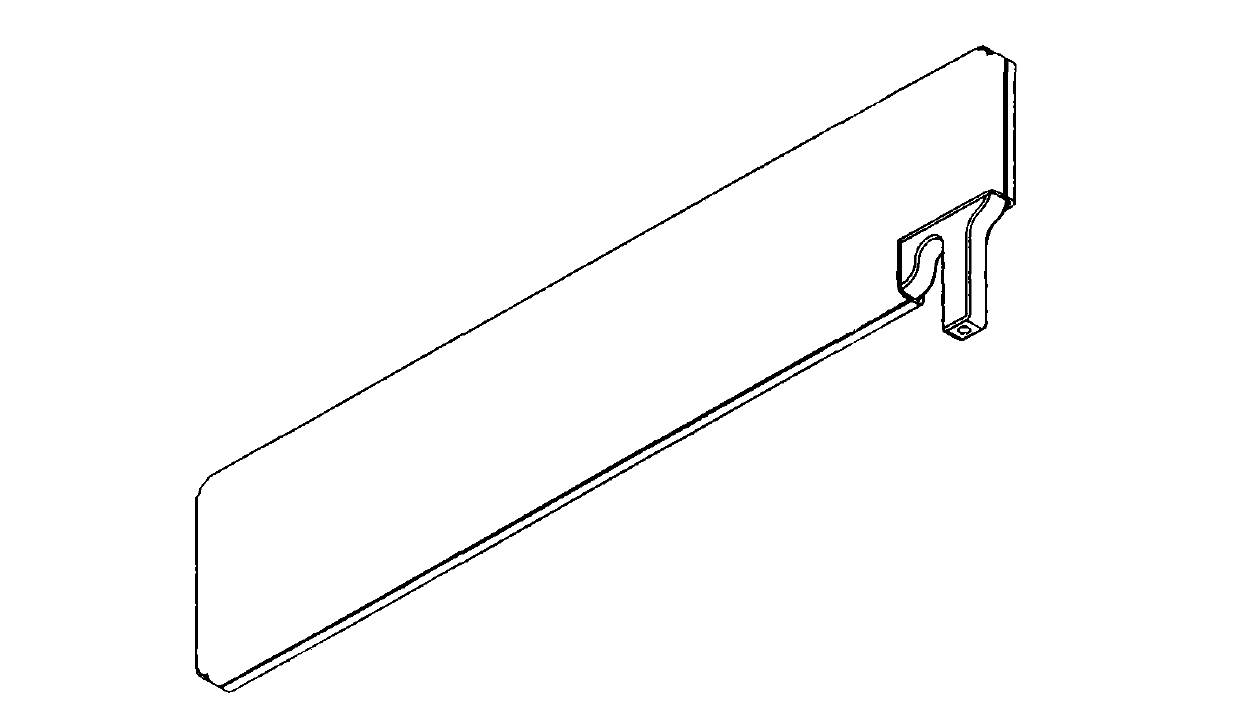

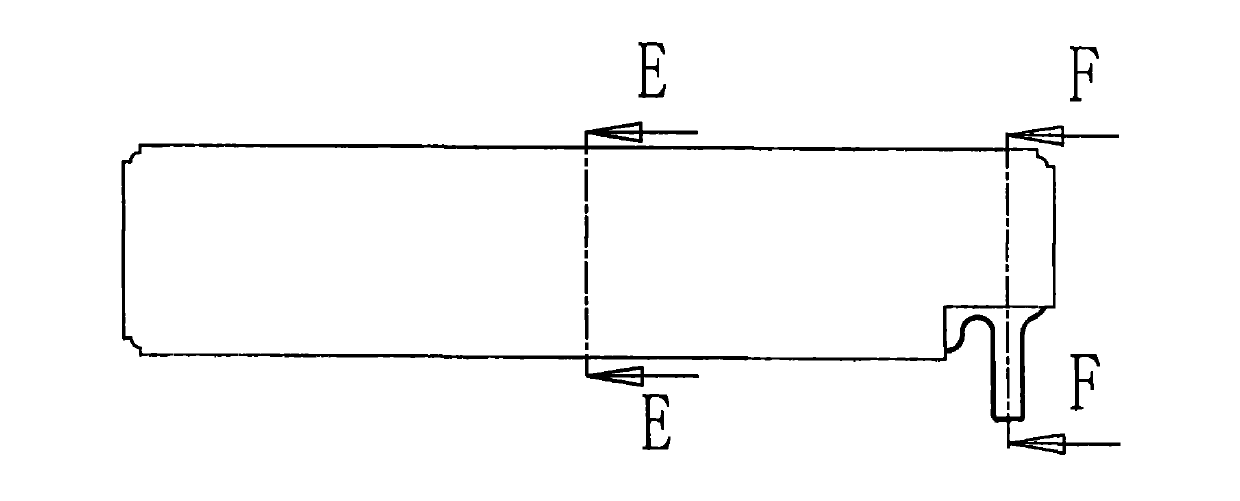

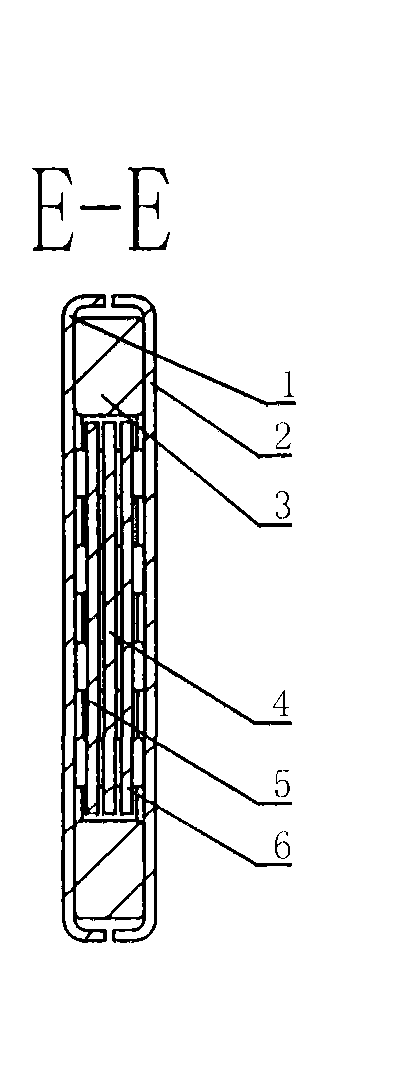

[0042] Figure 1A It is a schematic diagram of the three-dimensional structure of the hot plate of the metal fiber felt liquid-absorbing core of the present invention; Figure 1B It is a schematic diagram of the overall structure of the hot plate of the metal fiber felt liquid-absorbing core of the present invention; Figure 1C yes Figure 1B E-E direction sectional schematic diagram of ; Figure 1D yes Figure 1B The schematic diagram of the F-F direction section. It can be seen from the figure that the hot plate of the metal fiber felt liquid-absorbing core of the present invention is in the shape of a long straight plate, mainly including a sealed casing, a first metal fiber felt liquid-absorbing core 5, a second metal fiber felt liquid-absorbing core 6, and a support frame 4 and heat-conducting liquid working medium, the support frame 4, the first metal fiber felt liquid-absorbing core 5, and the second metal fiber felt liquid-absorbing core 6 are installed inside the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com