Manufacturing method of electrode of carbon nanotube film electric heating device

A carbon nanotube film and a production method technology, applied in ohmic resistance electrodes, ohmic resistance heating parts, electric heating devices, etc., can solve problems such as affecting the service life of electric heating devices, polymer aging, and increasing costs, and achieve stable resistance, Easy to handle, avoids aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

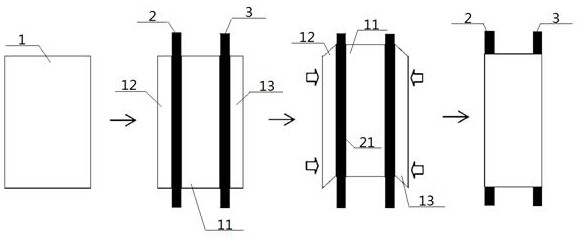

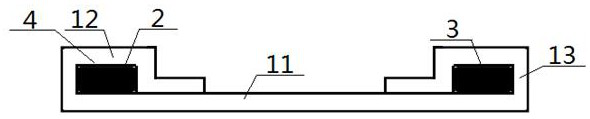

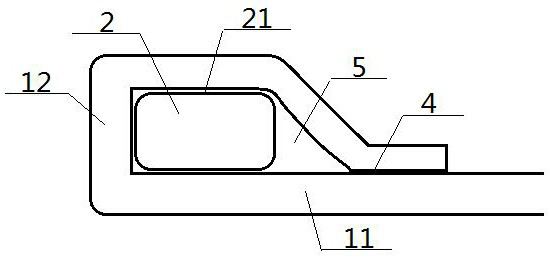

[0053] See figure 1 - Figure 4 , A method of fabricating a carbon nanotube membrane electrotherm electrode, comprising the step of: first tile the carbon nanotube film 1 (preferably carbon nanotube film 1 is self-supporting carbon nanotube film), and then in carbon nano-tube film 1 The left electrode strip 2 is placed on the top surface, the right electrode strip 3 (the left electrode strip 2, the right electrode strip 3 is made of a conductive metal material), the left electrode strip 2, the right electrode strip 3 is separated from each other, carbon nanotube film 1 On the left electrode strip 2, the region between the right electrode strips 3 is the bottom film 11, and the carbon nanotube film 1 is located on the left side of the left electrode strip 2 is the left fold film 12, and the carbon nanotube film 1 is located on the right. The area of the right side of the electrode strip 3 is the right folding film 13, and then fold the left fold film 12 over the top surface of the...

Embodiment 2

[0055] Basic content is the same as in Example 1. The difference is:

[0056] When the left electrode strip 2, the right electrode strip 3 is placed on the top surface of the carbon nanotube film 1, the left electrode strip 2, the bottom of the right electrode strip 3 is connected to the top surface of the carbon nanotube film 1 by the bonding material.

Embodiment 3

[0058] Basic content is the same as in Example 1. The difference is:

[0059] The conductive metal material is any of copper, aluminum, iron and silver. Any one of water, acetone, alcohol, and alcohol liquid; any of the alcoholic liquids is methanol, ethanol, and propanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com