Heat pipe, heat pipe multiporous structure and its mfg. method

A porous structure and heat pipe technology, applied in the field of heat pipes, can solve the problems of damaged heat pipes, dry burning, and inability to quickly replenish evaporated liquids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

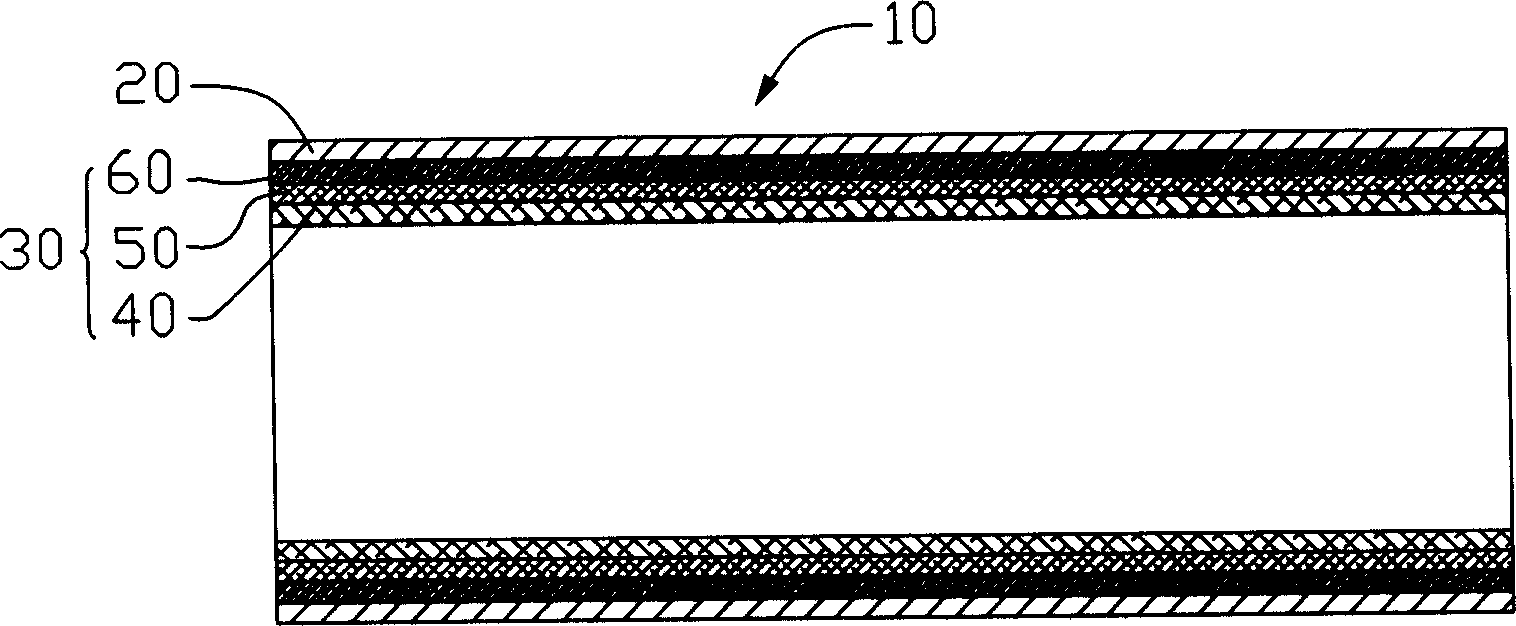

[0021] Such as figure 1 As shown, the heat pipe 10 includes a pipe body 20 , a porous structure 30 in close contact with the inner wall of the pipe body 20 and a working liquid filled in the pipe body 20 .

[0022] The tube body 20 is made of a metal material with good thermal conductivity, such as copper, etc. The cross section of the tube body 20 is circular, and the cross section of the tube body 20 can also be in other shapes, such as roughly oval, triangular, rectangular and other polygonal shapes. Wait. The working liquid filled in the pipe body 20 is generally a liquid with a low boiling point, such as water, alcohol and the like.

[0023] The porous structure 30 is composed of three layers of wire mesh with approximately equal thickness and in close contact with each other. The inner layer wire mesh 40 , the middle layer wire mesh 50 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com