Heat pipe

A technology for heat pipes and adiabatic sections, applied to heat pipes. It can solve problems such as small fluid return resistance and large capillary force that cannot be taken into account at the same time, and achieve the effects of increasing anti-gravity characteristics, reducing return resistance, and accelerating boiling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

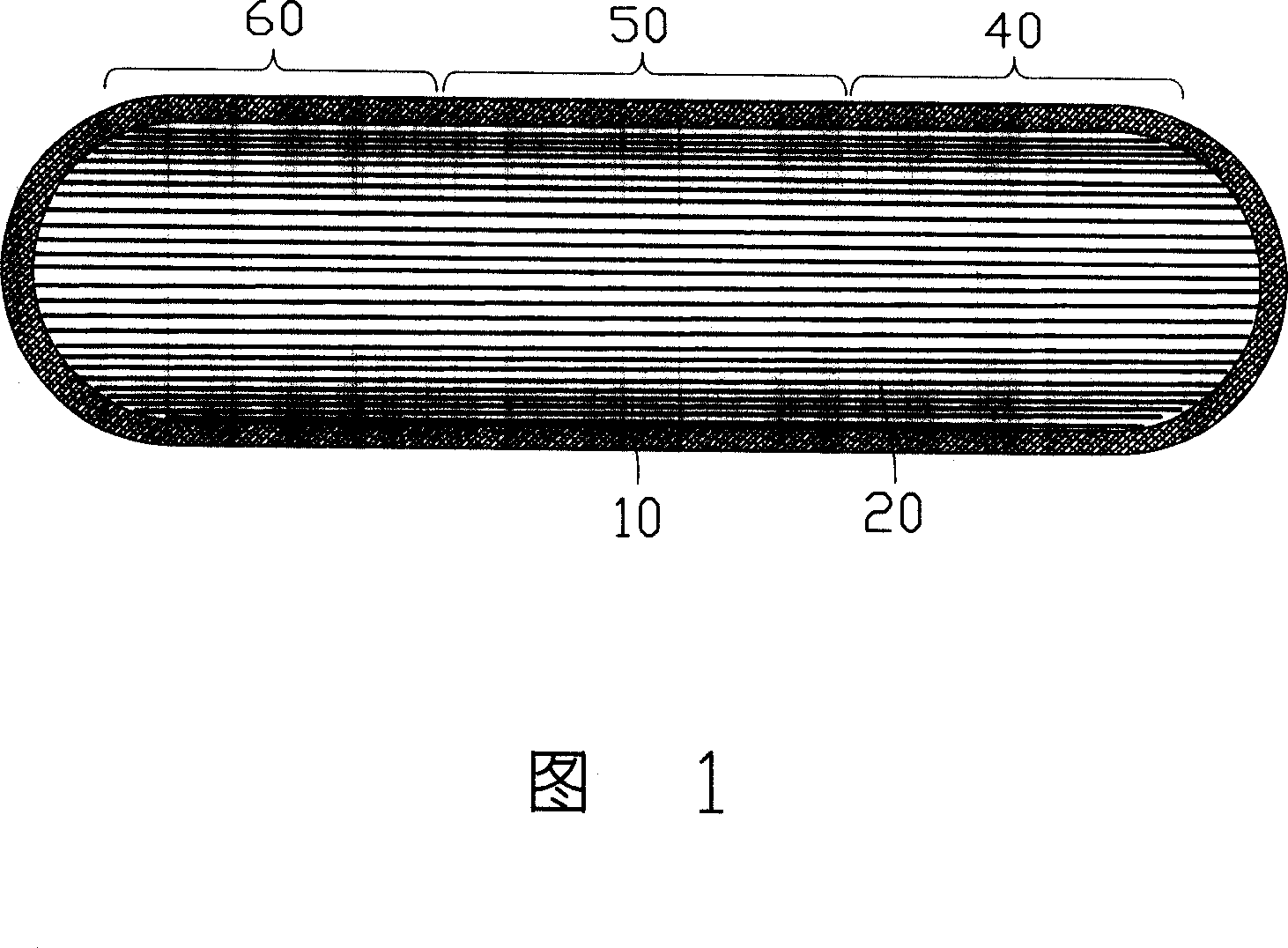

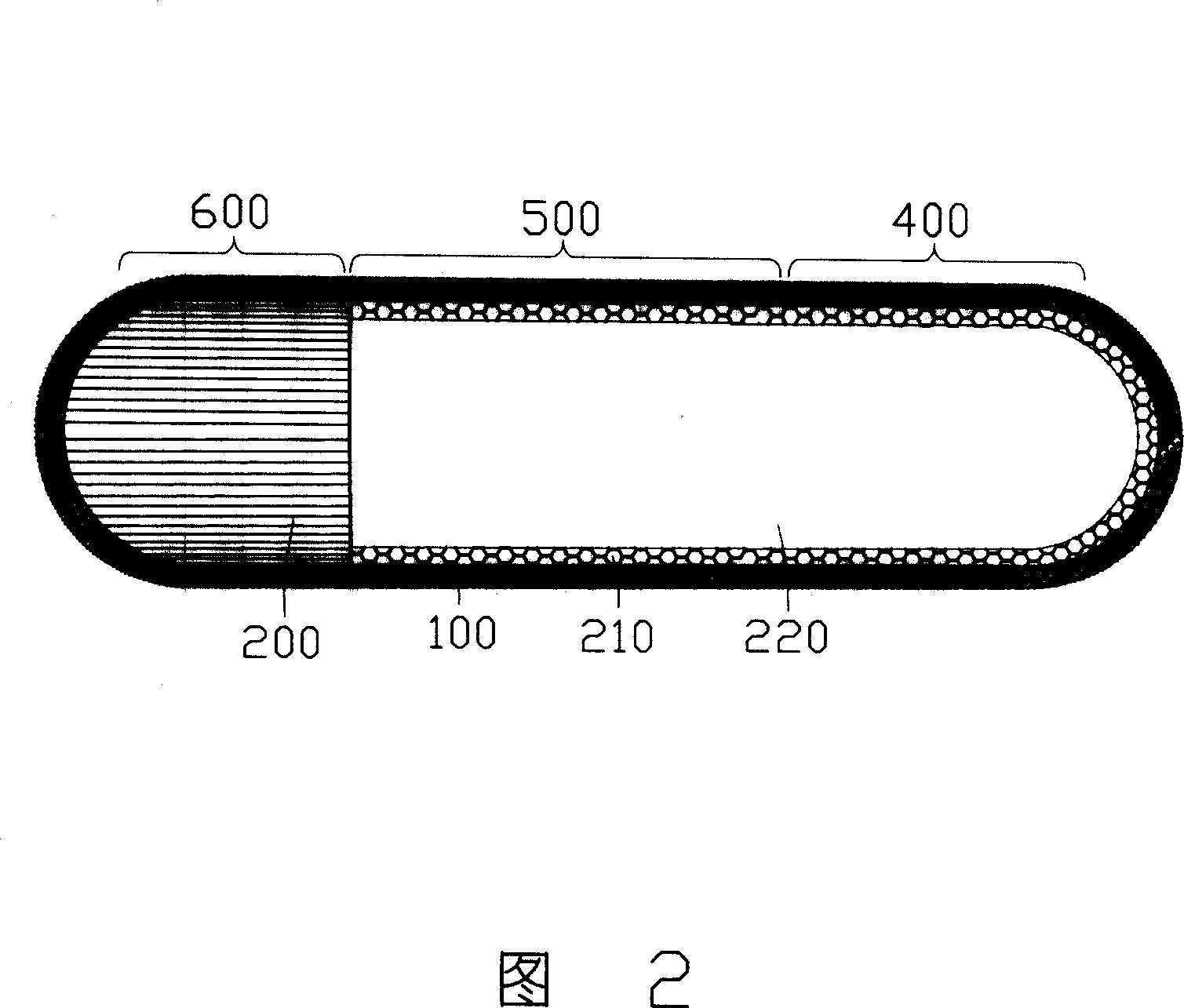

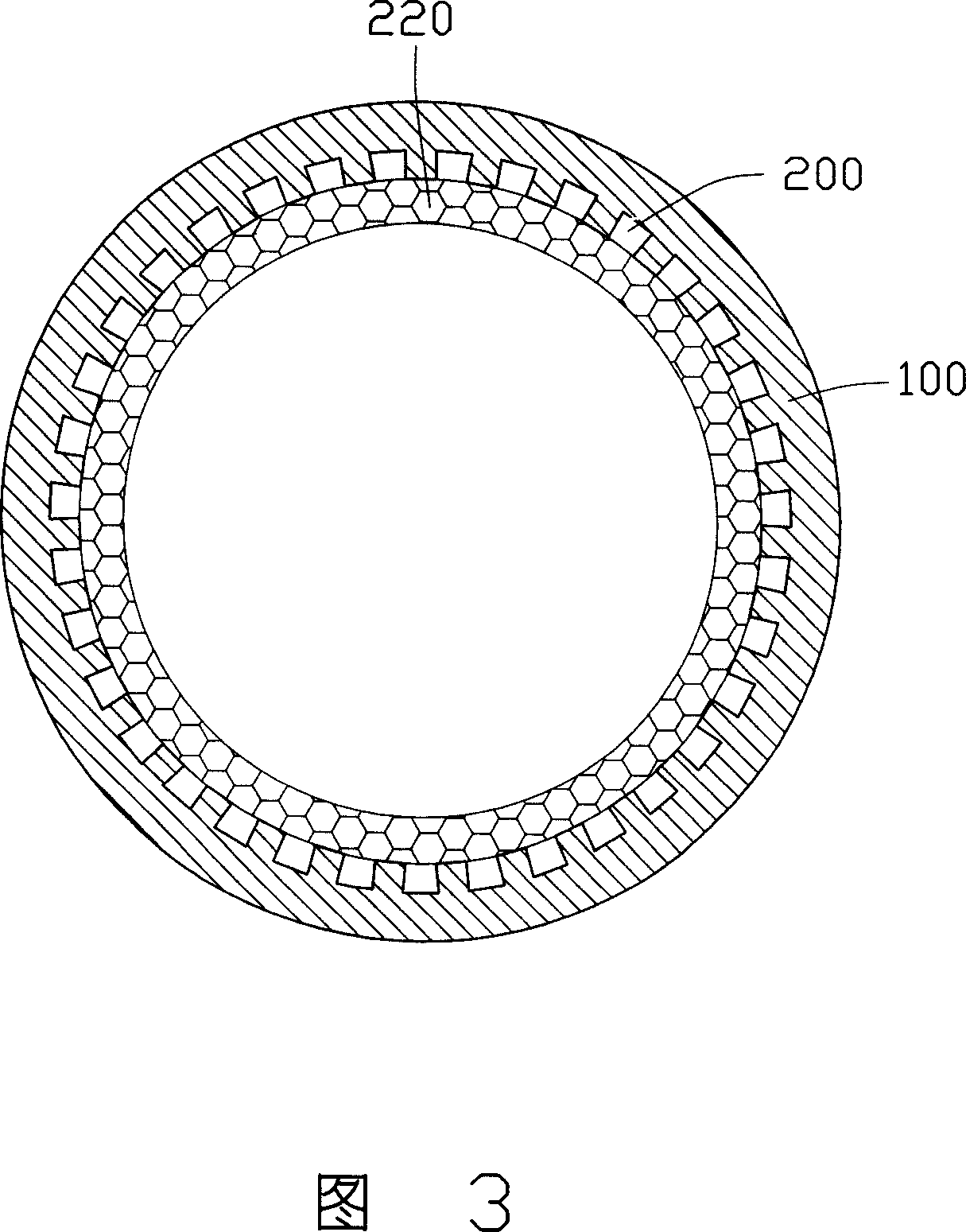

[0016] Fig. 2 and Fig. 3 are respectively the axial section of the first embodiment of the heat pipe of the present invention and the cross-sectional schematic diagram of the heat insulating section 500 thereof. The heat pipe is an example of a straight heat pipe, which mainly includes a housing 100 , a capillary structure disposed on the inner wall of the housing 100 , and an appropriate amount of working fluid (not shown) sealed in the housing 100 . The casing 100 can be made of metal materials with good thermal conductivity such as copper and aluminum, and the inside thereof is generally evacuated into a vacuum or close to a vacuum to facilitate the evaporation of the working fluid when heated. The working liquid is generally a liquid with high latent heat such as water, alcohol, ammonia water and their mixtures.

[0017] According to the functions, the heat pipe is divided into three parts: an evaporation section 400 , an adiabatic section 500 , and a condensation section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com