Composite liquid absorption core for loop heat pipe

A loop heat pipe and liquid-absorbing core technology, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the phase change of circulating working fluid, the inability to balance the return resistance of the liquid-absorbing core and the capillary pressure head, and small return resistance, etc. problem, to achieve the effect of simple manufacturing process, favorable start-up and low backflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

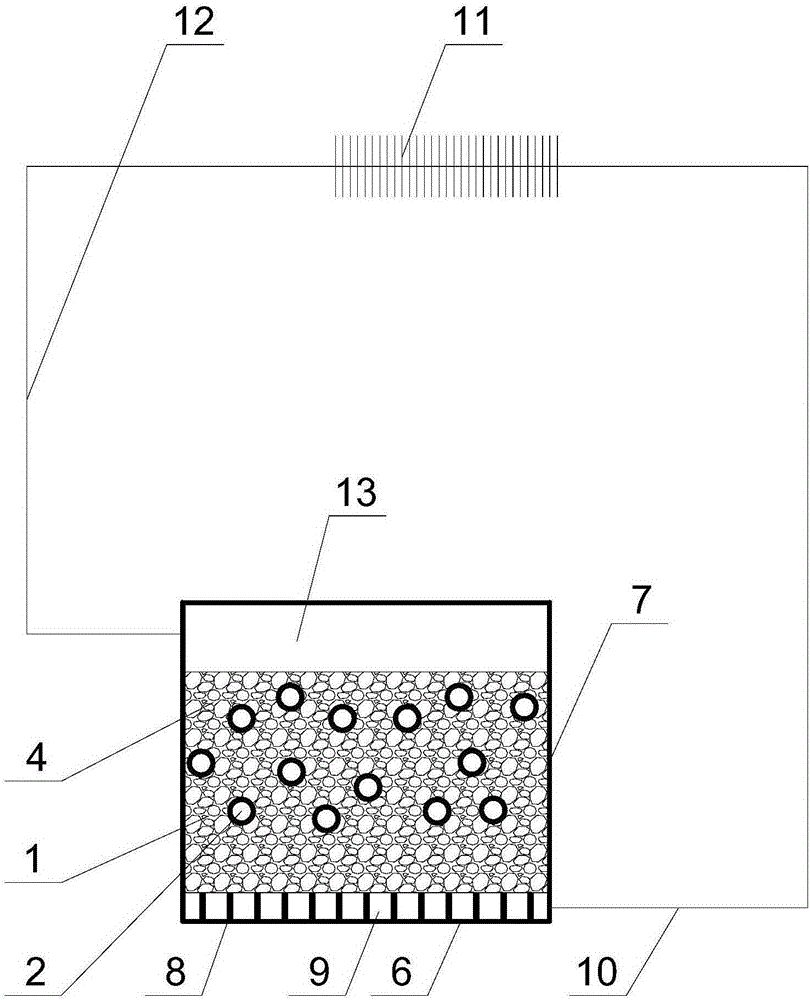

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

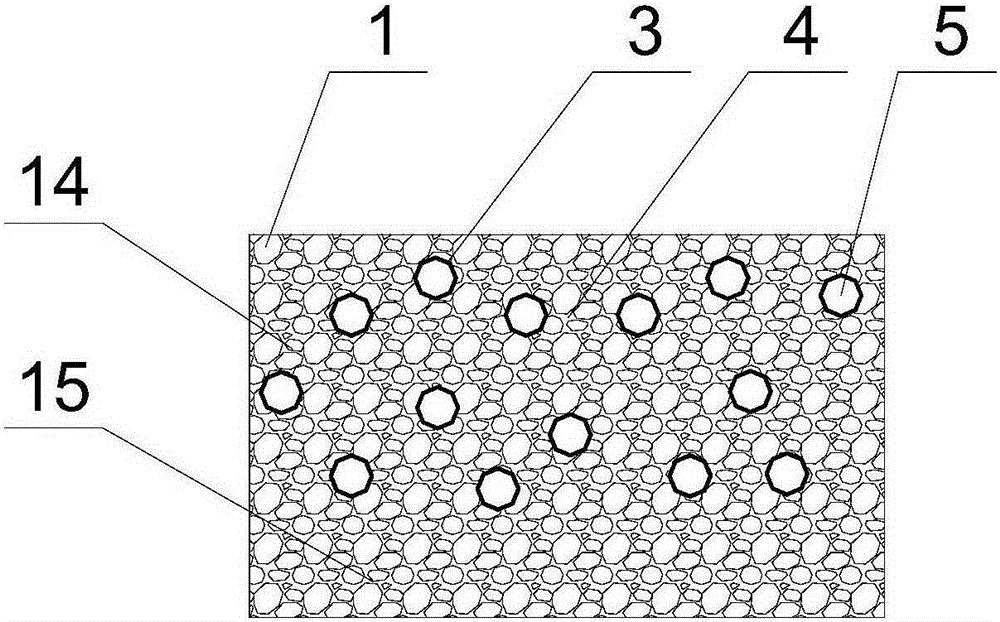

[0015] see Figure 1-Figure 2 , a composite liquid-absorbing core for a loop heat pipe of the present invention is composed of metal powder 1, phase change balls 2 and pores 4; the metal powder 1 is a metal powder with a diameter of 25-150 microns, which can be copper powder or nickel Powder, the preferred copper powder of the present invention is used as the material of the liquid-absorbing core; The phase-change bead 2 is made of a phase-change bead shell 3 and a phase-change material 5, and the diameter of the phase-change bead 2 is 1-3mm, so The preferred nickel of the phase-change pellet shell 3 is its constituent material; the selection of the phase-change material 5 should be selected according to the actual operating temperature of the loop heat pipe, and the solid-liquid phase transition temperature of the phase-change materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com