Micro-crack flat heat pipe and manufacturing method thereof

A technology of a flat heat pipe and a manufacturing method, applied in the field of electronics, can solve the problem of insufficient heat dissipation capability of the heat pipe, and achieve the effects of simple and easy technical means, improved heat transfer, and low backflow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

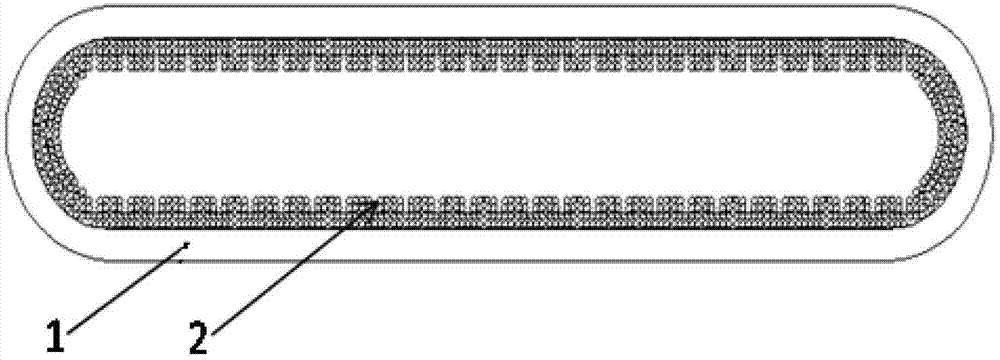

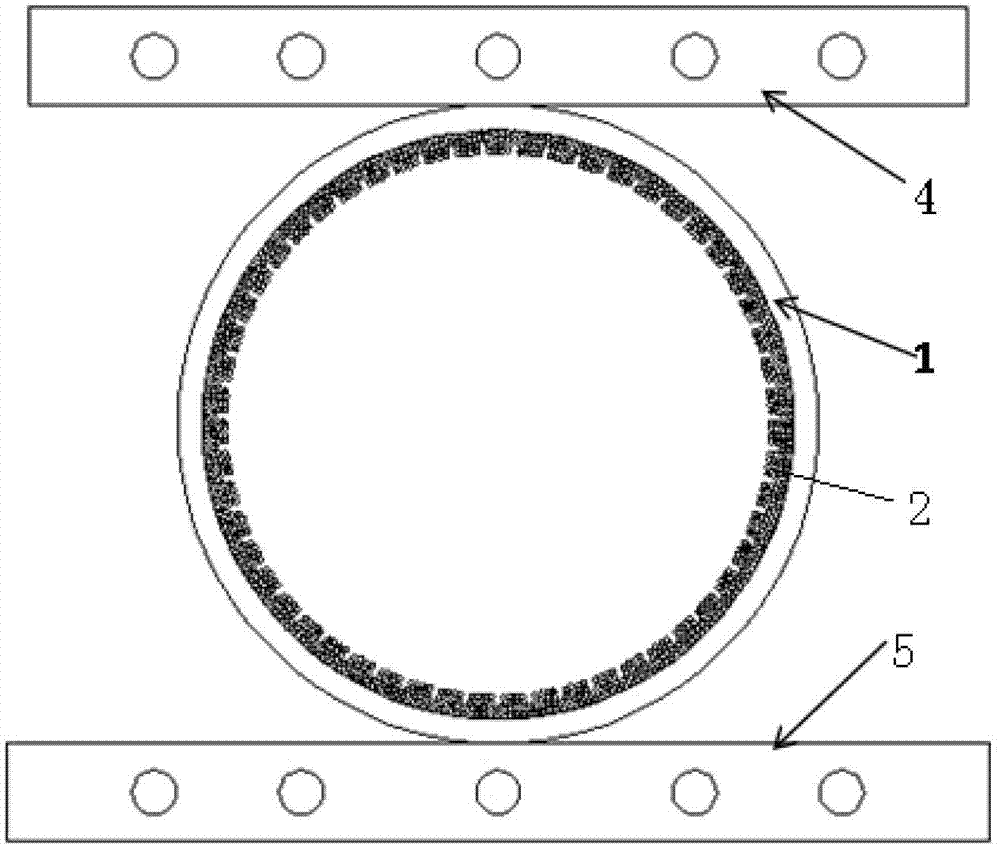

[0029] Such as Figure 1~4 shown. The micro-crack flat heat pipe of the present invention comprises a pipe body 1 and a porous capillary layer 2 attached to the inner wall of the pipe body 1; the surface of the porous capillary layer 2 has a plurality of grooves, which are evenly distributed along the circumference of the inner wall of the pipe body 1; The tube body 1 adopts a metal flat heat pipe, and the tube body 1 is filled with deionized distilled water or ethanol.

[0030] The manufacturing method of the micro-crack flat heat pipe of the present invention can be realized through the following steps:

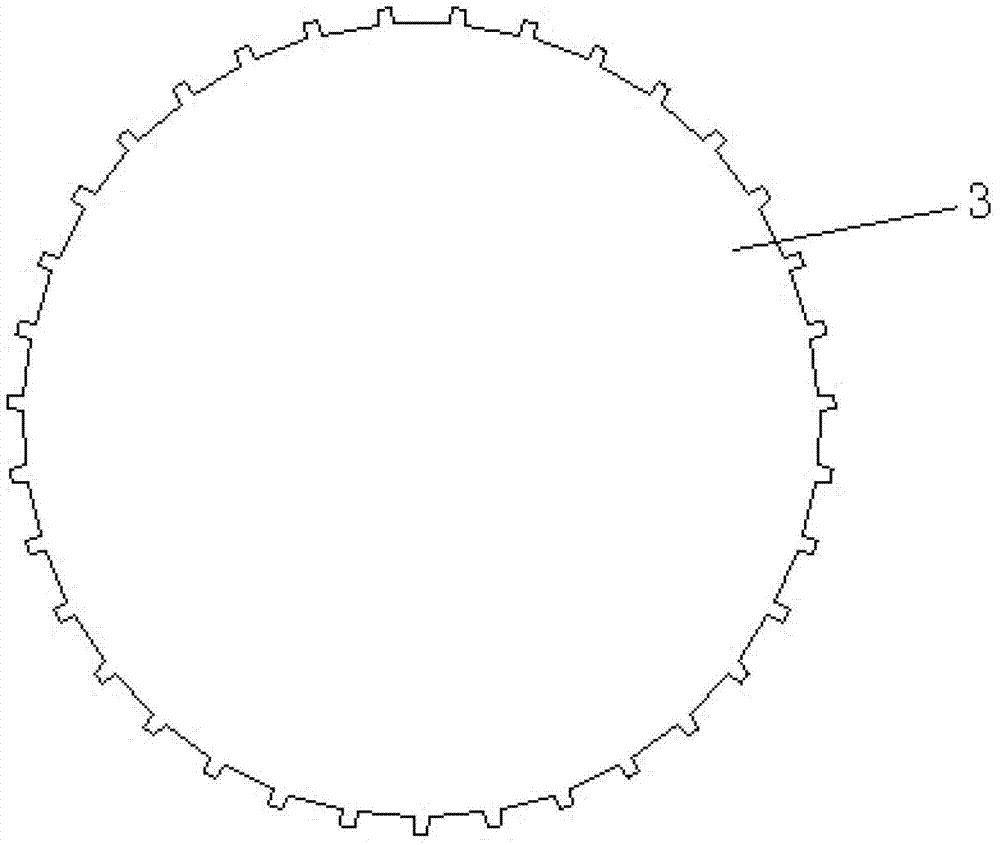

[0031] (1) Prepare a tube body 1 (circular metal heat pipe) and a sintered mandrel 3, the diameter of the sintered mandrel is smaller than the inner diameter of the tube body 1, place the sintered mandrel in the middle of the tube body 1, and the tube body There is a gap between 1 and the sintered mandrel 3; one end of the tube body 1 is retracted, and then the tube body ...

Embodiment 2

[0040] This embodiment is the same as Embodiment 1 except for the following features.

[0041] Such as Figure 5 ~ Figure 7 shown. In the above step (1), grooves are opened on the inner surface of the pipe body 1 , and the surface of the sintered mandrel is a smooth surface (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com