Gas spring assembly

一种气弹簧、组件的技术,应用在弹簧、车辆弹簧、弹簧/减震器等方向,能够解决不能衰减振动频率范围等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

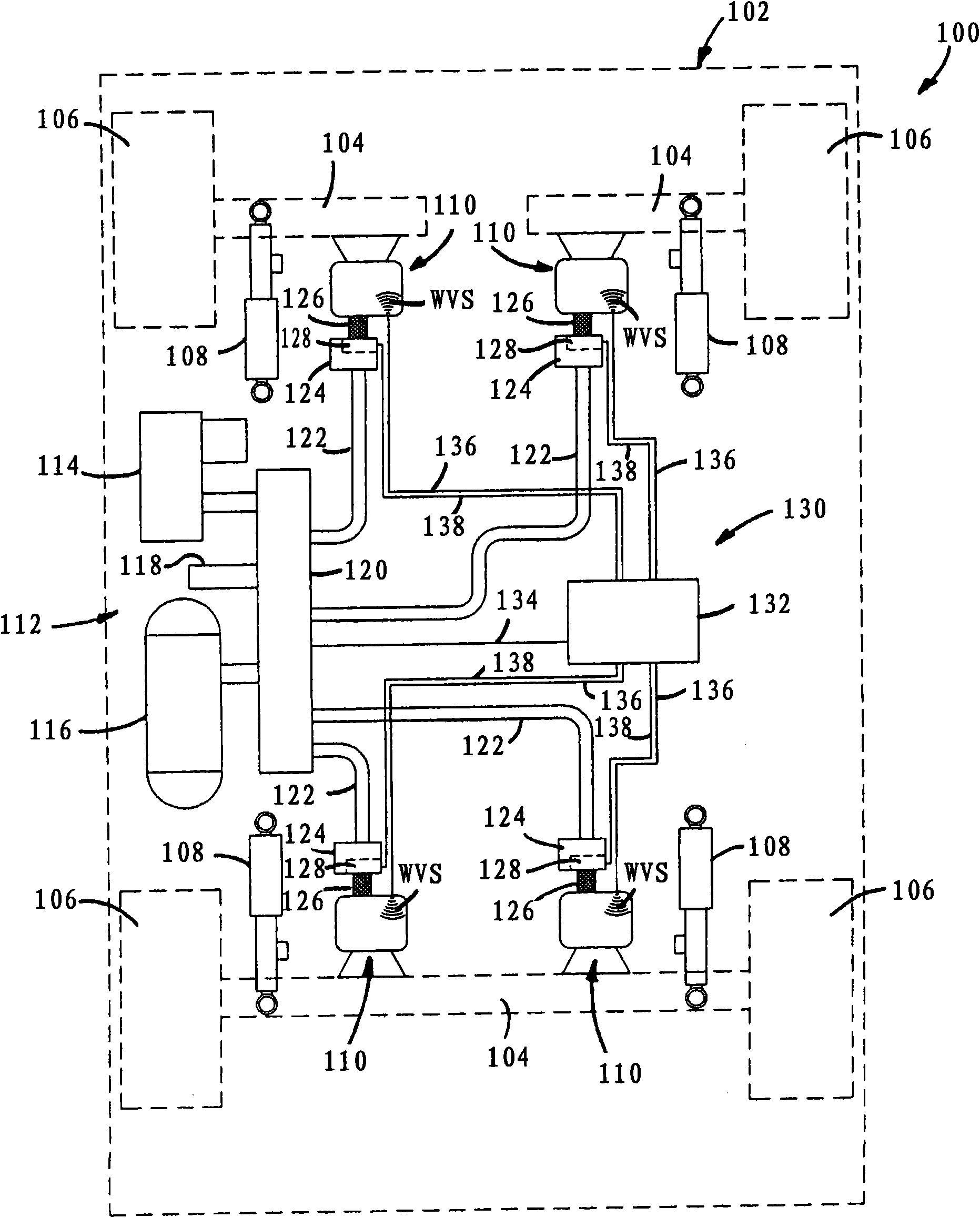

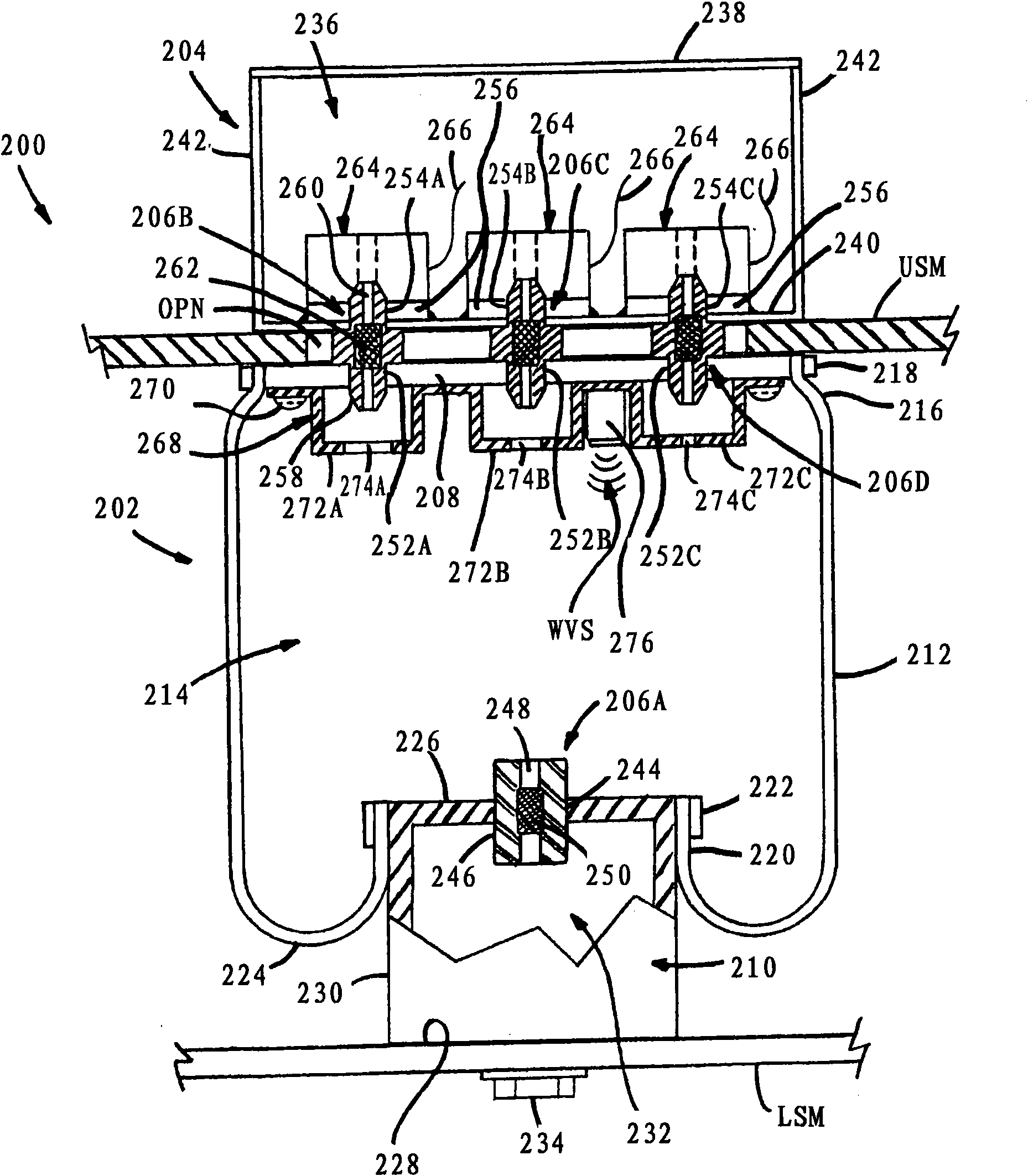

[0045] Turning now to the drawings, which are shown in order to illustrate exemplary embodiments of the novel concept and not to limit it, figure 1 A vehicle 100 is shown having a sprung mass, such as for example a body 102 , and an unsprung mass, such as for example an axle 104 and / or wheels 106 . In addition, a plurality of hydraulic dampers, such as the shock absorber 108, can be fixed in a suitable manner between the sprung and unsprung masses of the vehicle. However, it will be appreciated that such dampers may optionally be included in figure 1 in a typical embodiment. Additionally, a plurality of gas spring assemblies 110 (which may also be referred to herein as "gas spring and gas damper assemblies") are disposed between the sprung and unsprung masses of the vehicle, such as figure 1 Between the adjacent wheel 106 and the shock absorber 108 shown in .

[0046] The vehicle 100 also includes a pressurized gas system 112 in communication with the gas spring assembly 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com