Thermoelectric generation module based on flat plate heat pipes and heat pipe circulation waste heat thermoelectric generation system formed by thermoelectric generation module based on flat plate heat pipes

A thermoelectric power generation module and technology of thermoelectric power generation, applied in the direction of generators/motors, electrical components, etc., can solve problems such as difficult large-scale power generation applications, large influence of pipeline systems, and small heat transfer of heat pipes, etc., to achieve flexible design and installation, reduce The effect of high product price and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

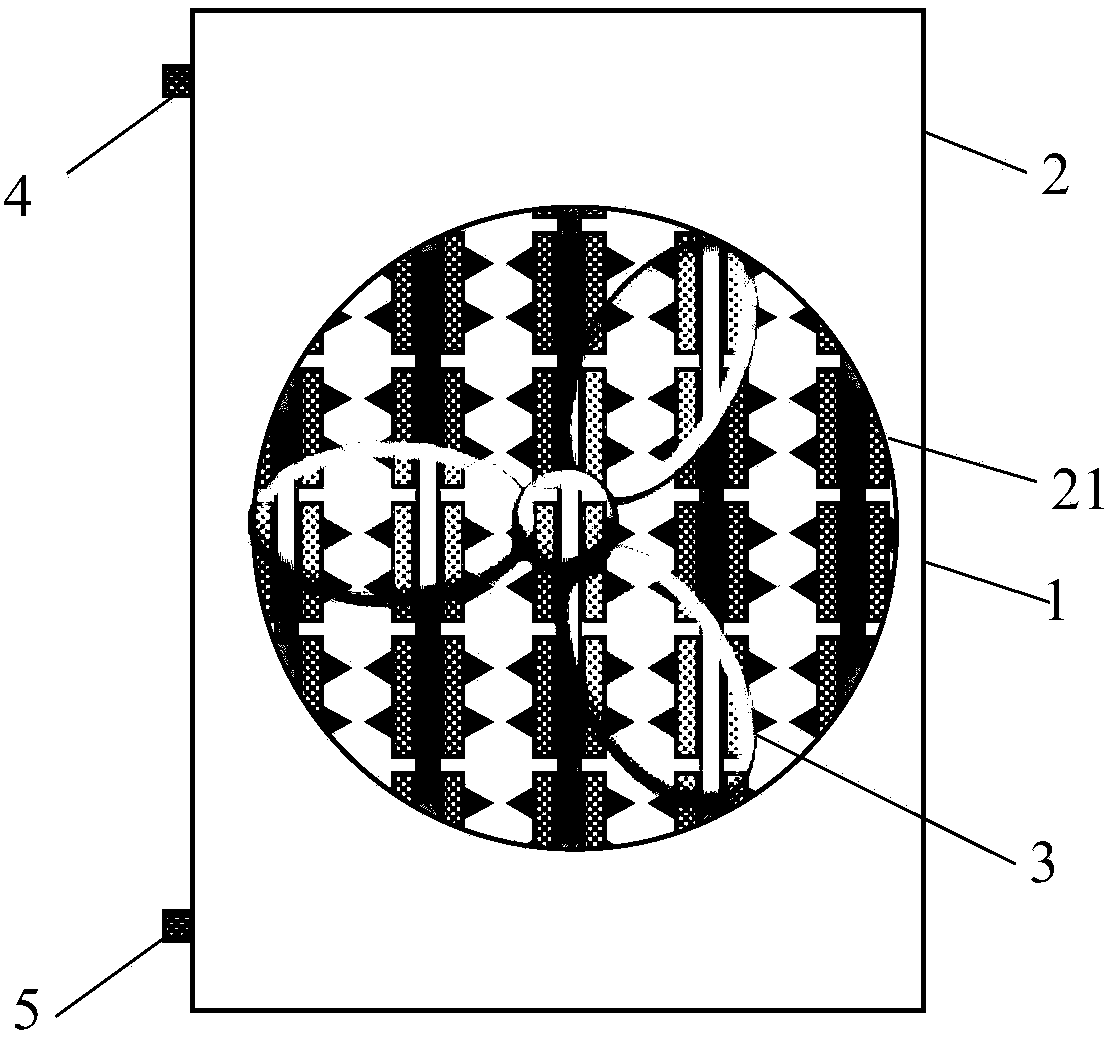

[0025] figure 1 It is a schematic structural diagram of a thermoelectric power generation module based on a flat heat pipe in the present invention, which is mainly composed of a thermoelectric power generation unit 1 , a housing 2 , a fan 3 , a gas interface 4 and a liquid interface 5 . The thermoelectric power generation unit 1 is assembled inside the casing 2 , and the casing 2 is provided with an airflow passage 21 at the front and back, and a fan 3 is provided at the front side of the airflow passage 21 .

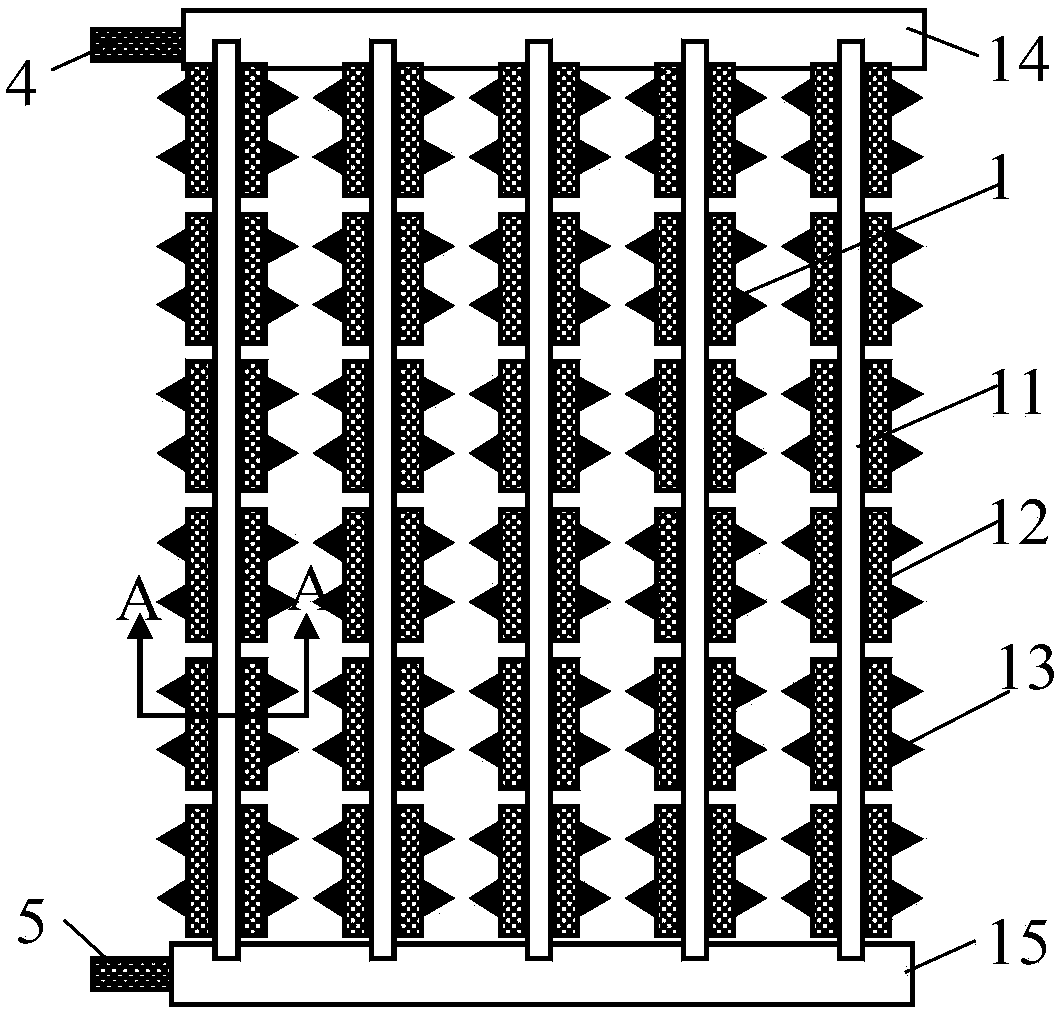

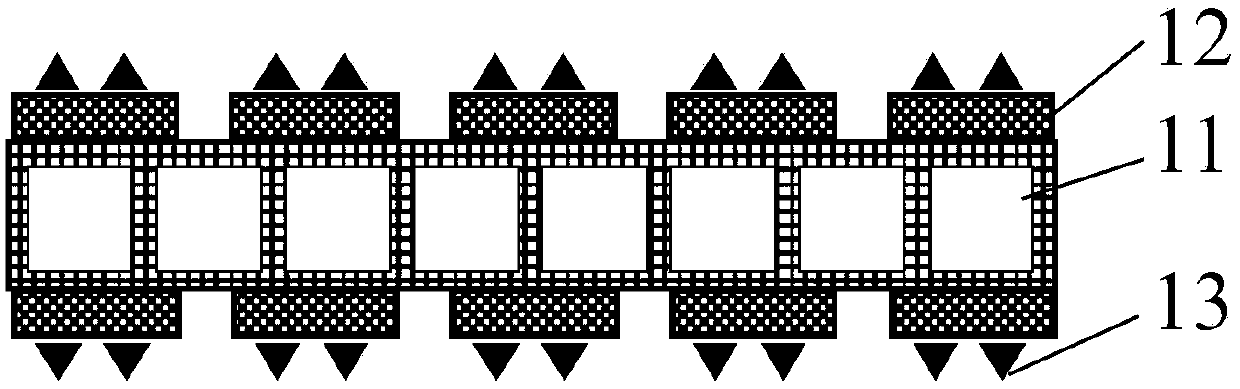

[0026] figure 2 It is a schematic diagram of the structure of the thermoelectric power generation unit 1. The thermoelectric power generation unit 1 is arranged in parallel with several groups of porous parallel flow flat tubes 11 from left to right. The upper and lower ends of the parallel flow flat tube 11 are inserted into the gas header 14 and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com