Patents

Literature

38results about How to "Improved Torque Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission

ActiveUS20110166752A1Reduce torqueReducing engine speedAnalogue computers for trafficGearing controlHydraulic machineryControl theory

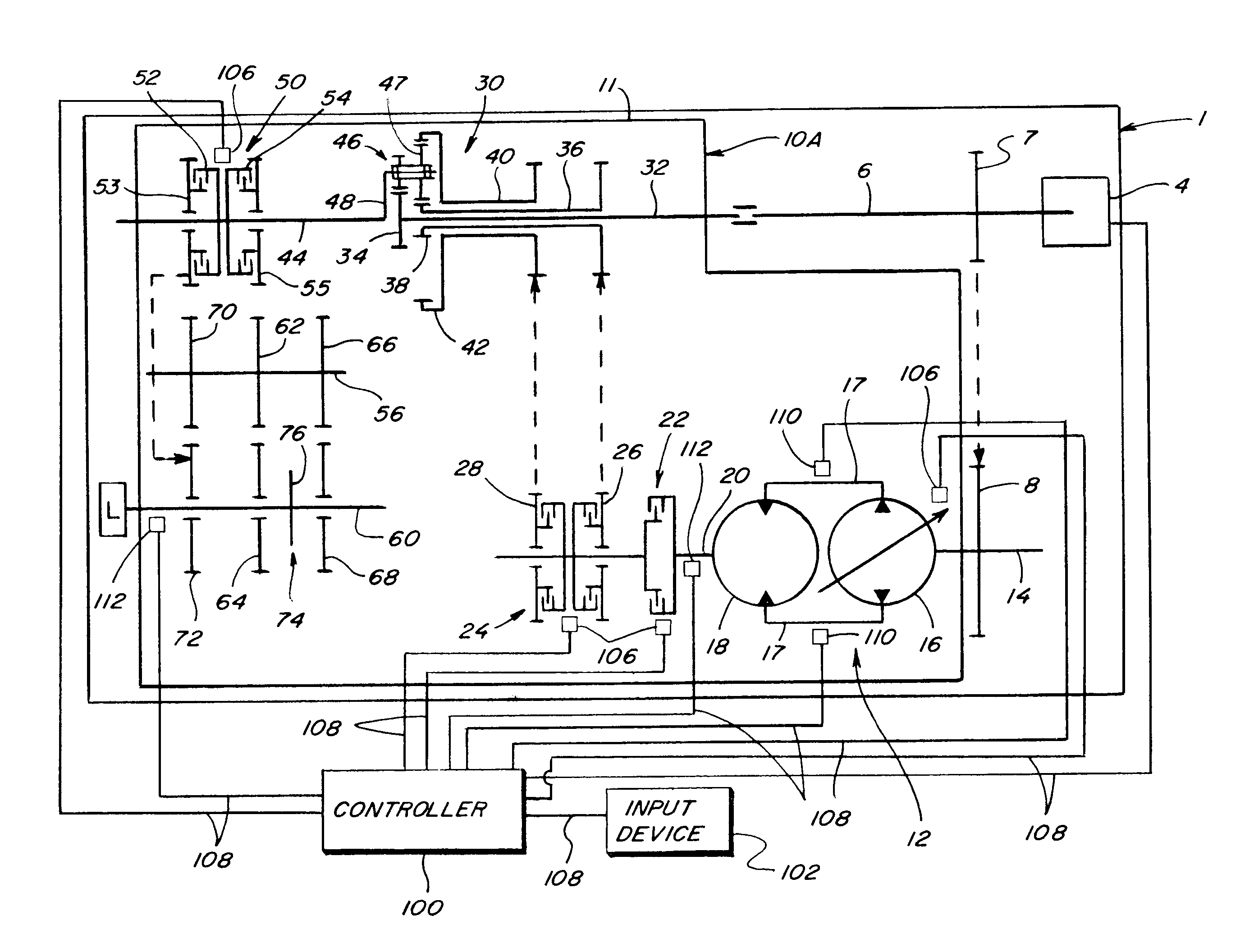

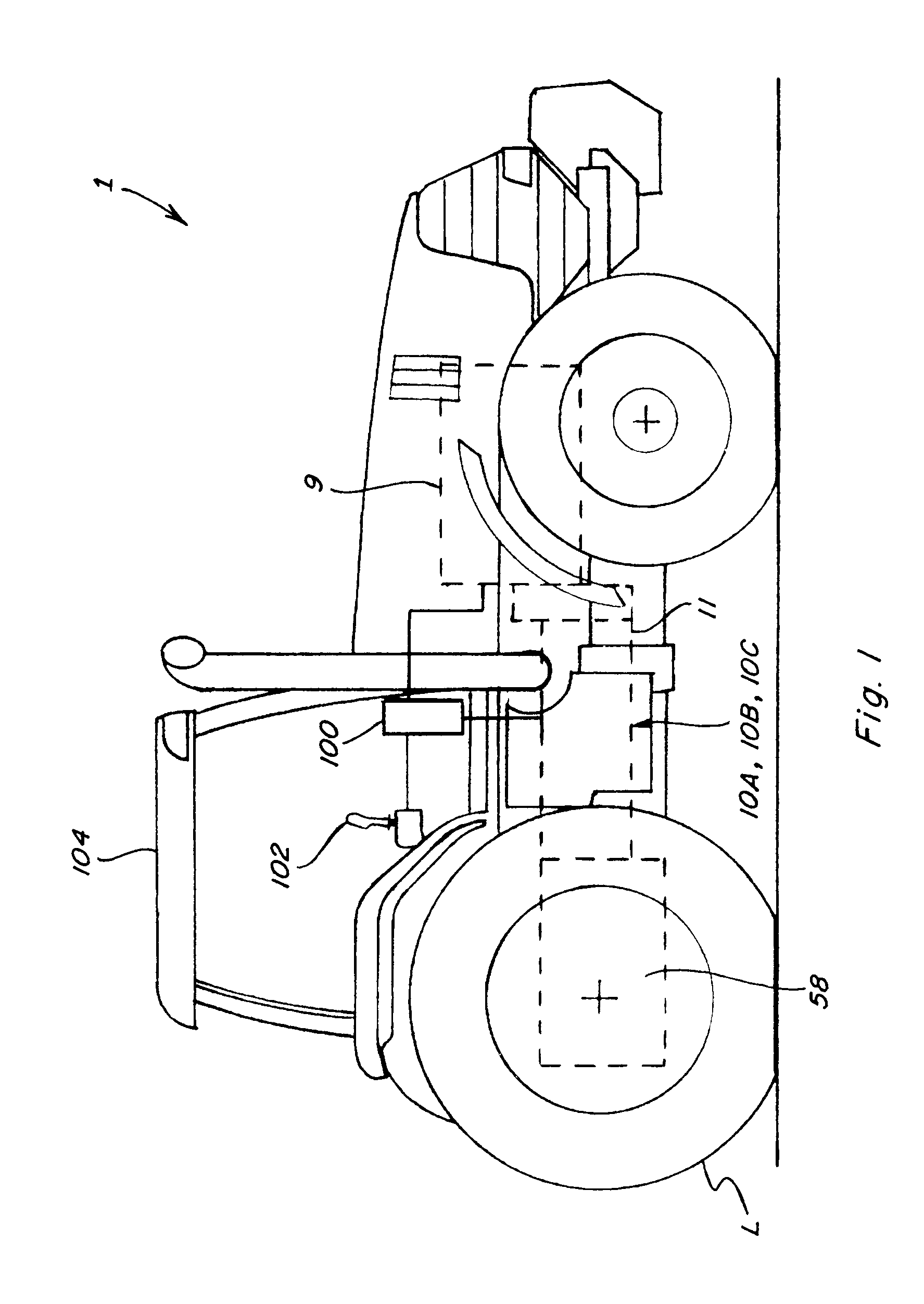

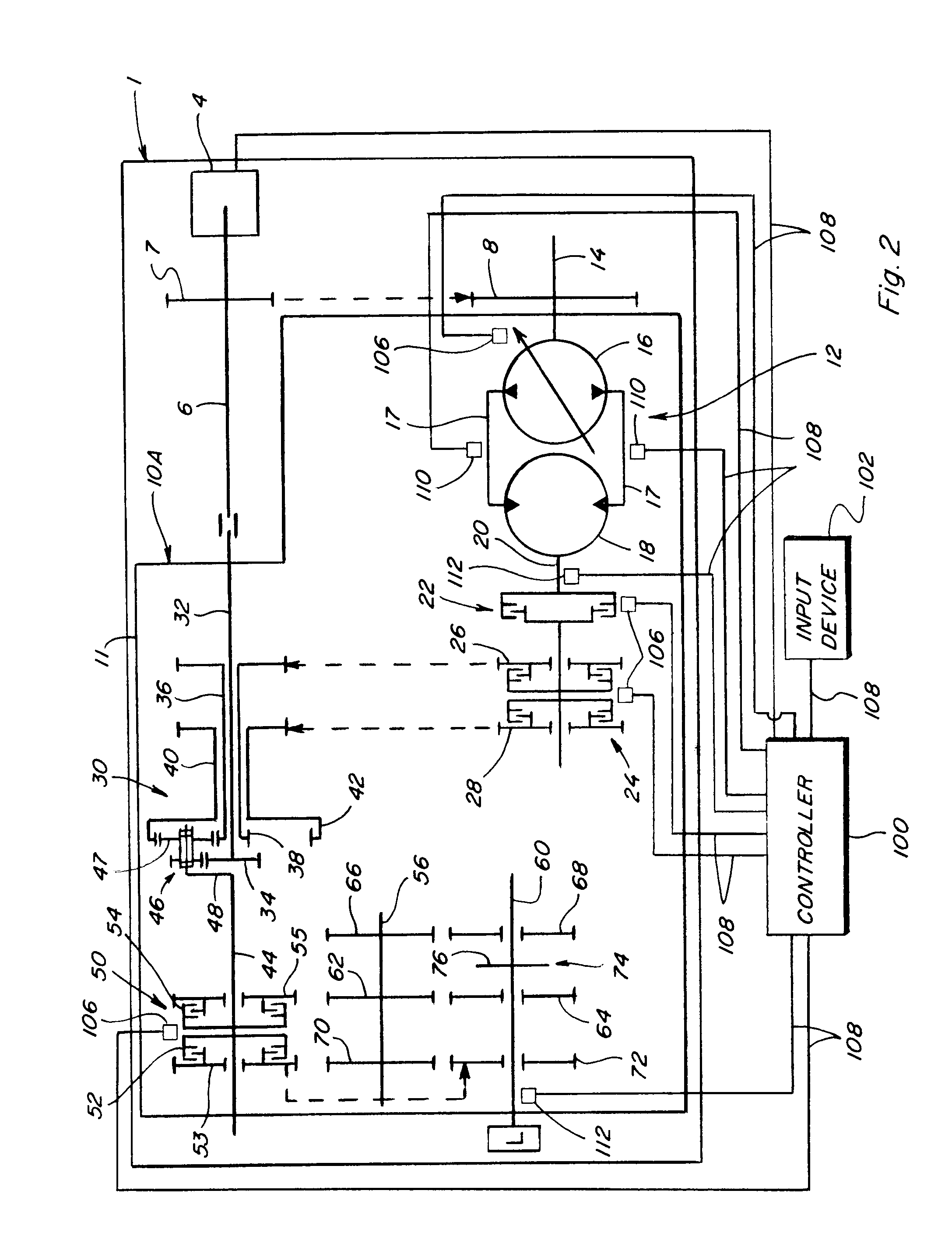

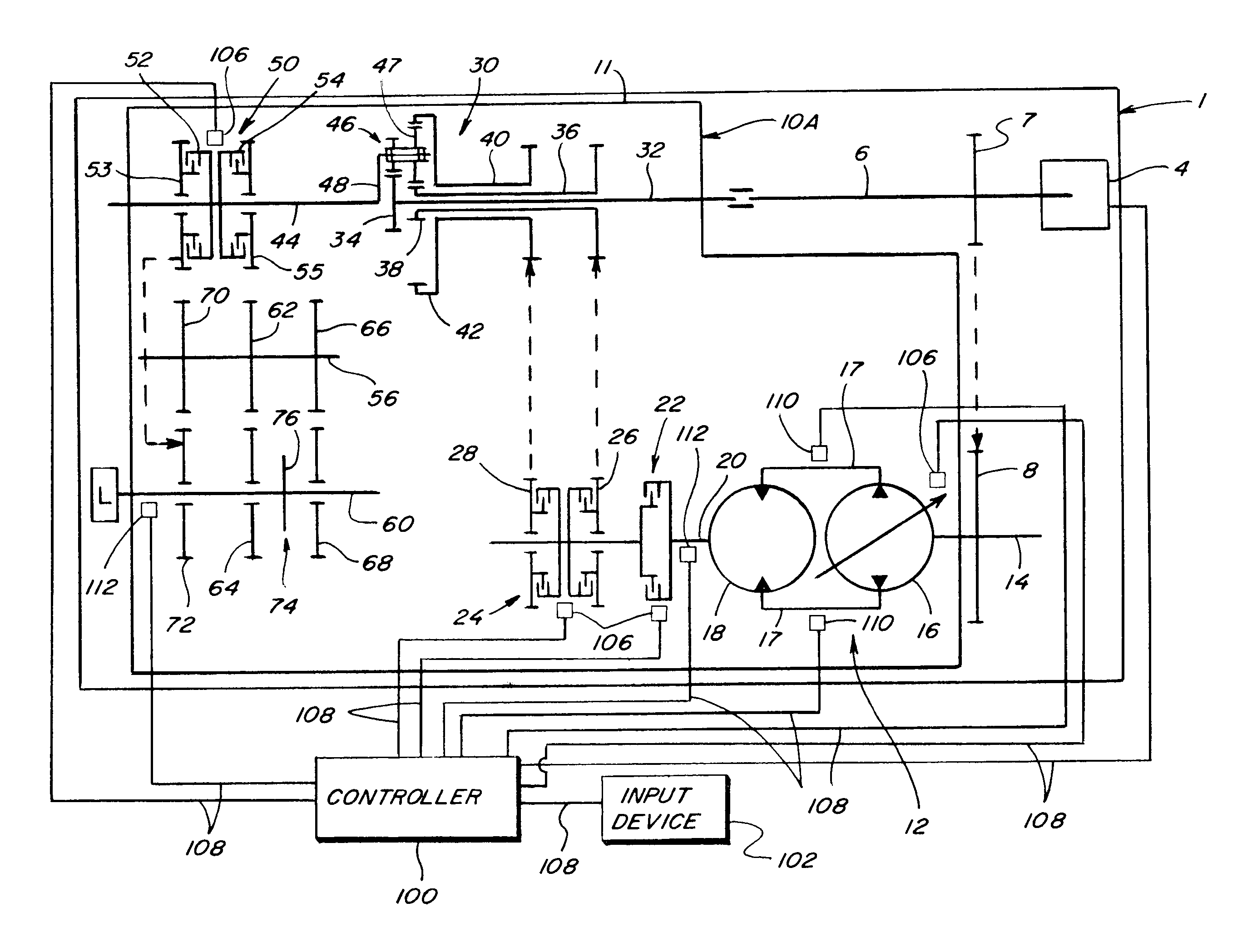

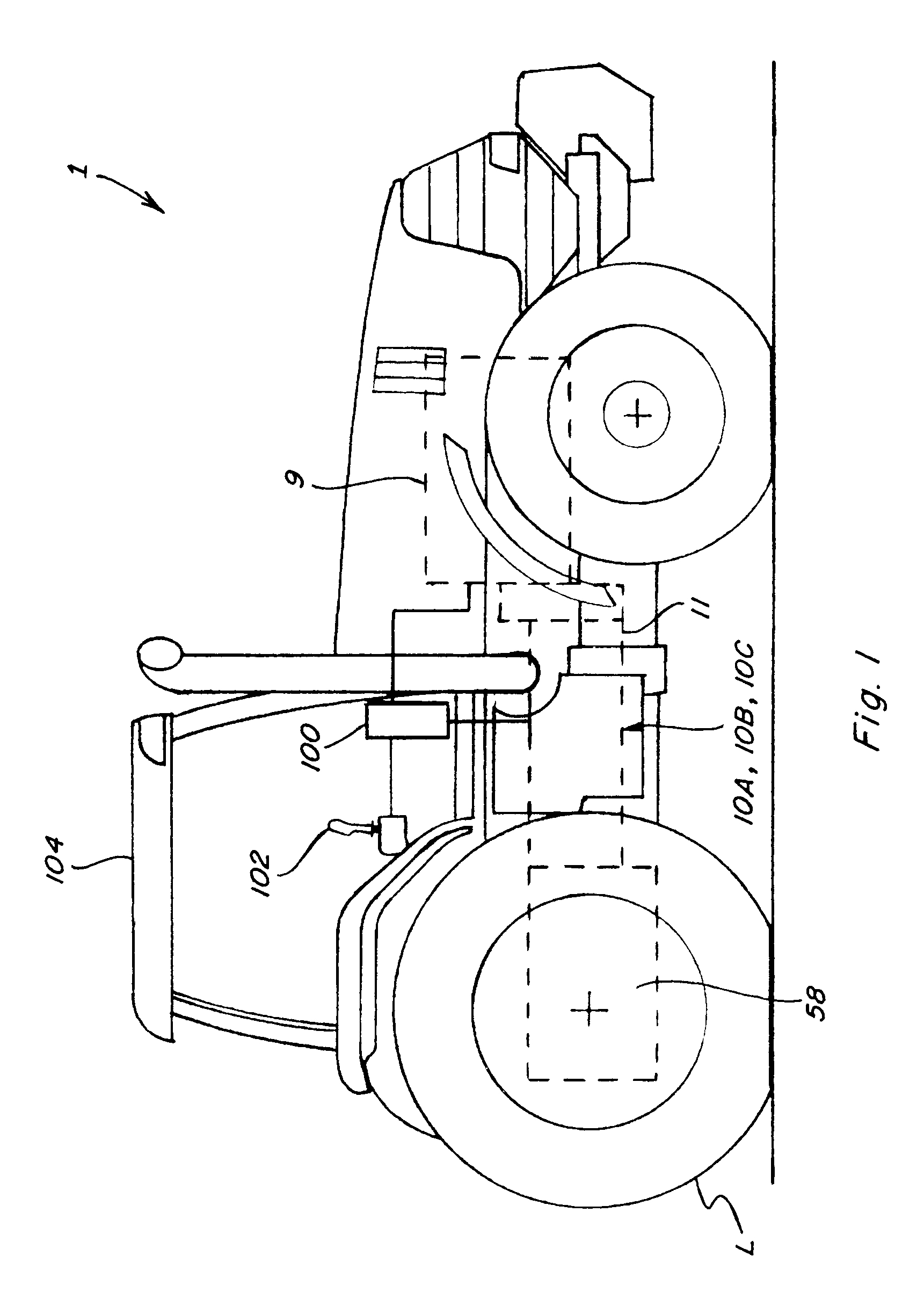

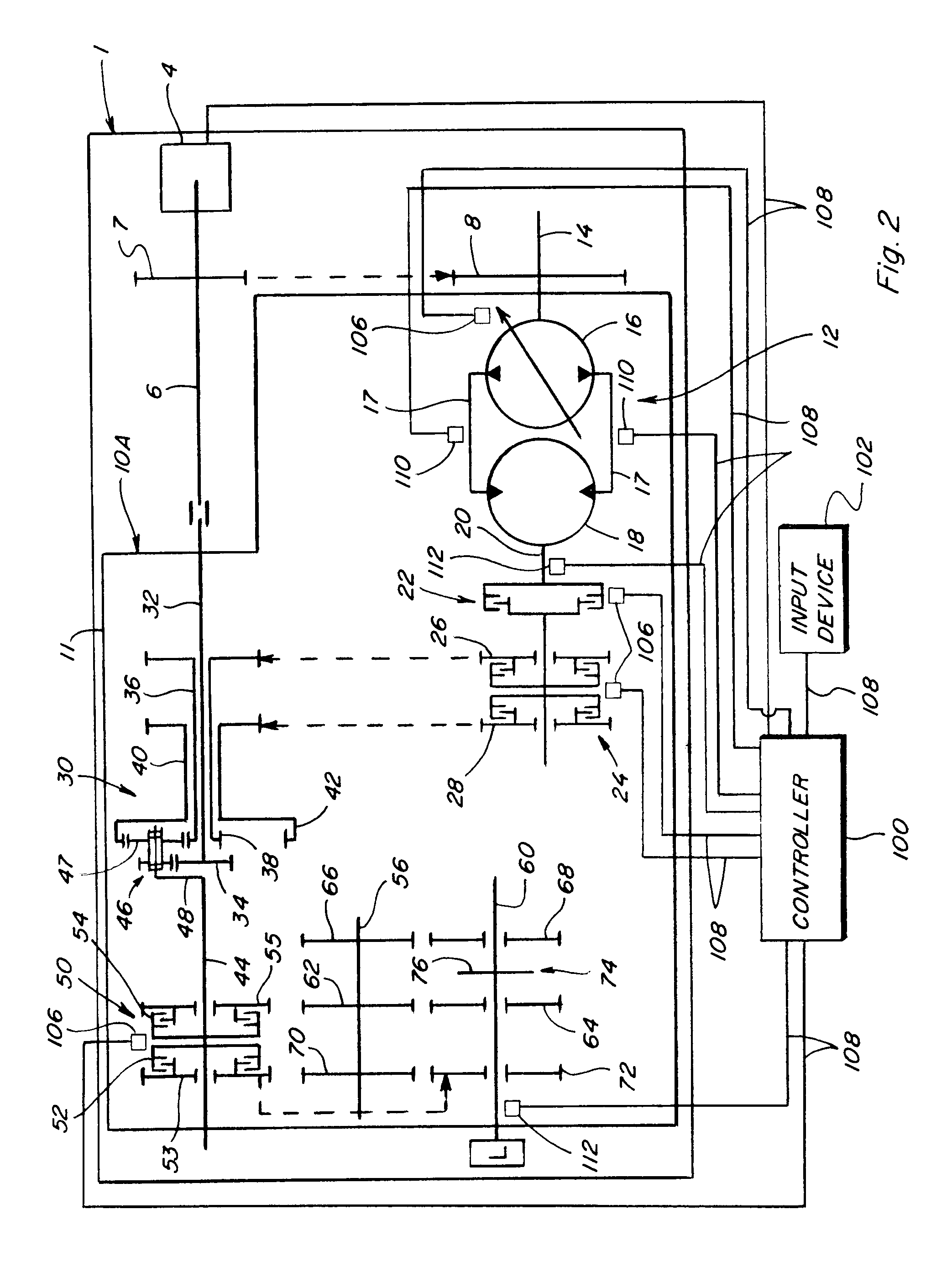

The method of estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission uses pressure data and other metrics of a hydrostatic power unit of the transmission in lieu of actual driveline torque data. A mechanical efficiency of the transmission is determined as a function of whether the power unit is operating in a power generation or regeneration mode, and the torque output of the power unit is estimated from that and other hydrostatic parameters. This is used to estimate a torque output of a planetary power unit of the transmission, and the torque on an output member of the driveline is then estimated using that value, and appropriate corrective action taken.

Owner:BLUE LEAF I P

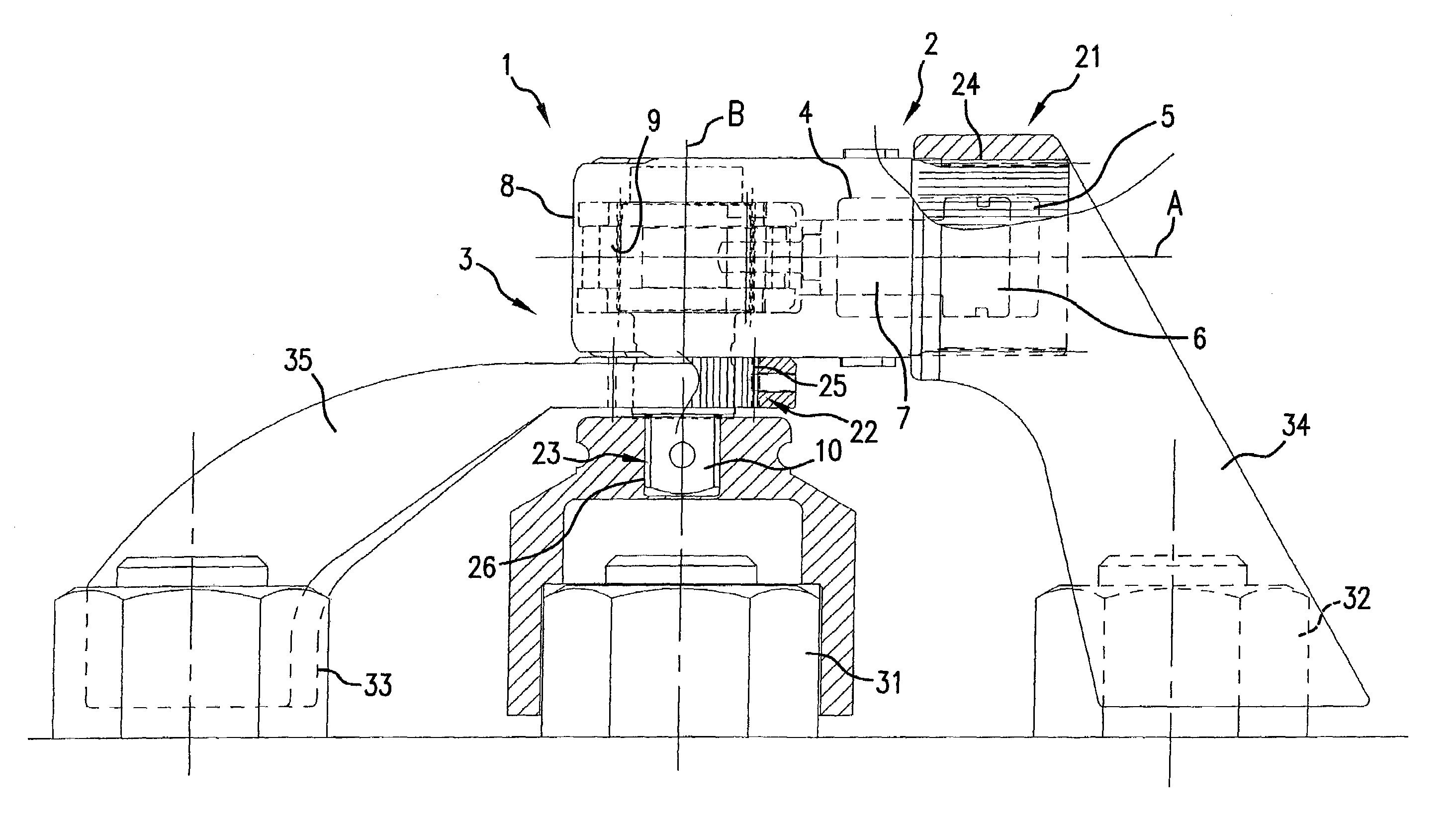

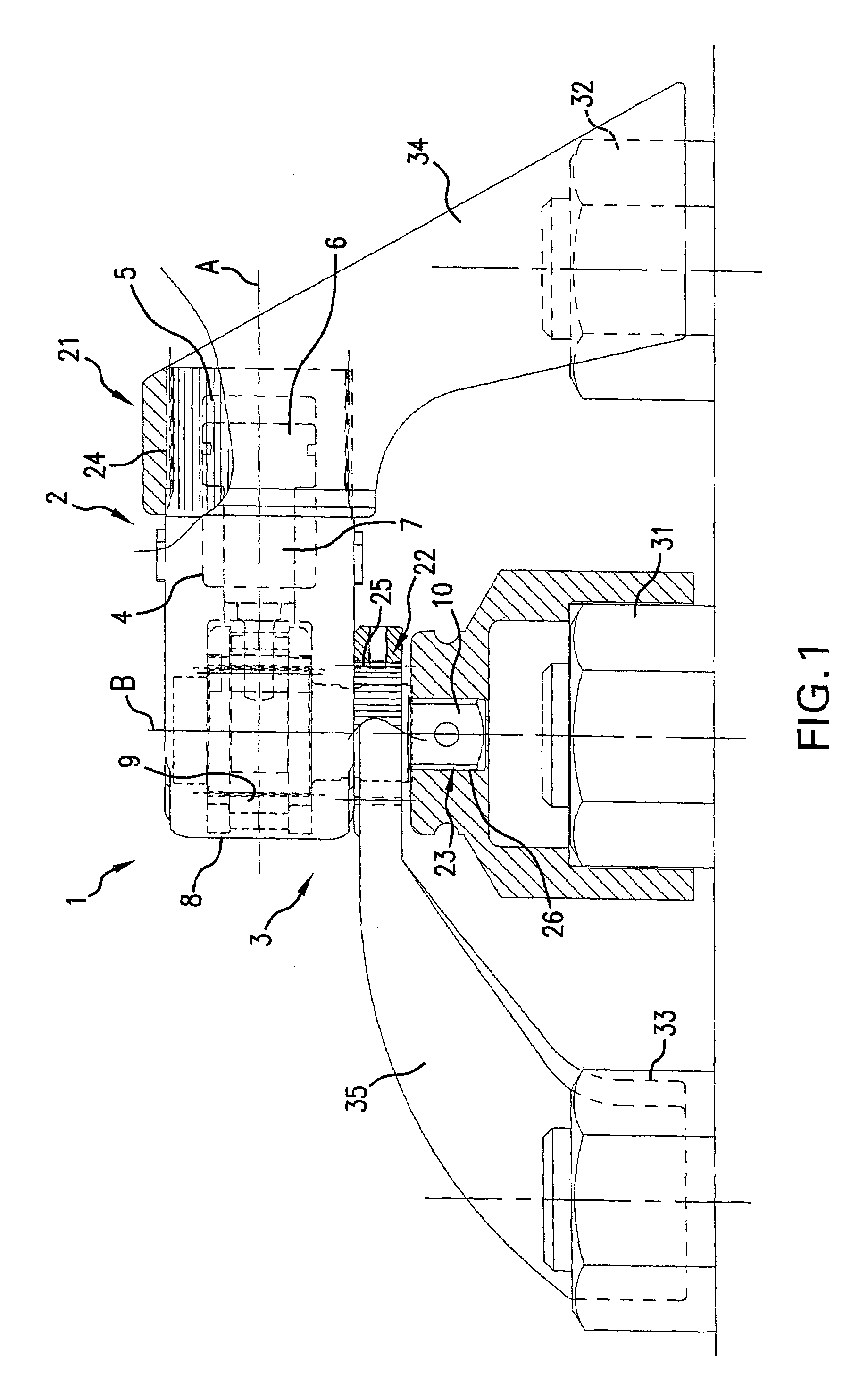

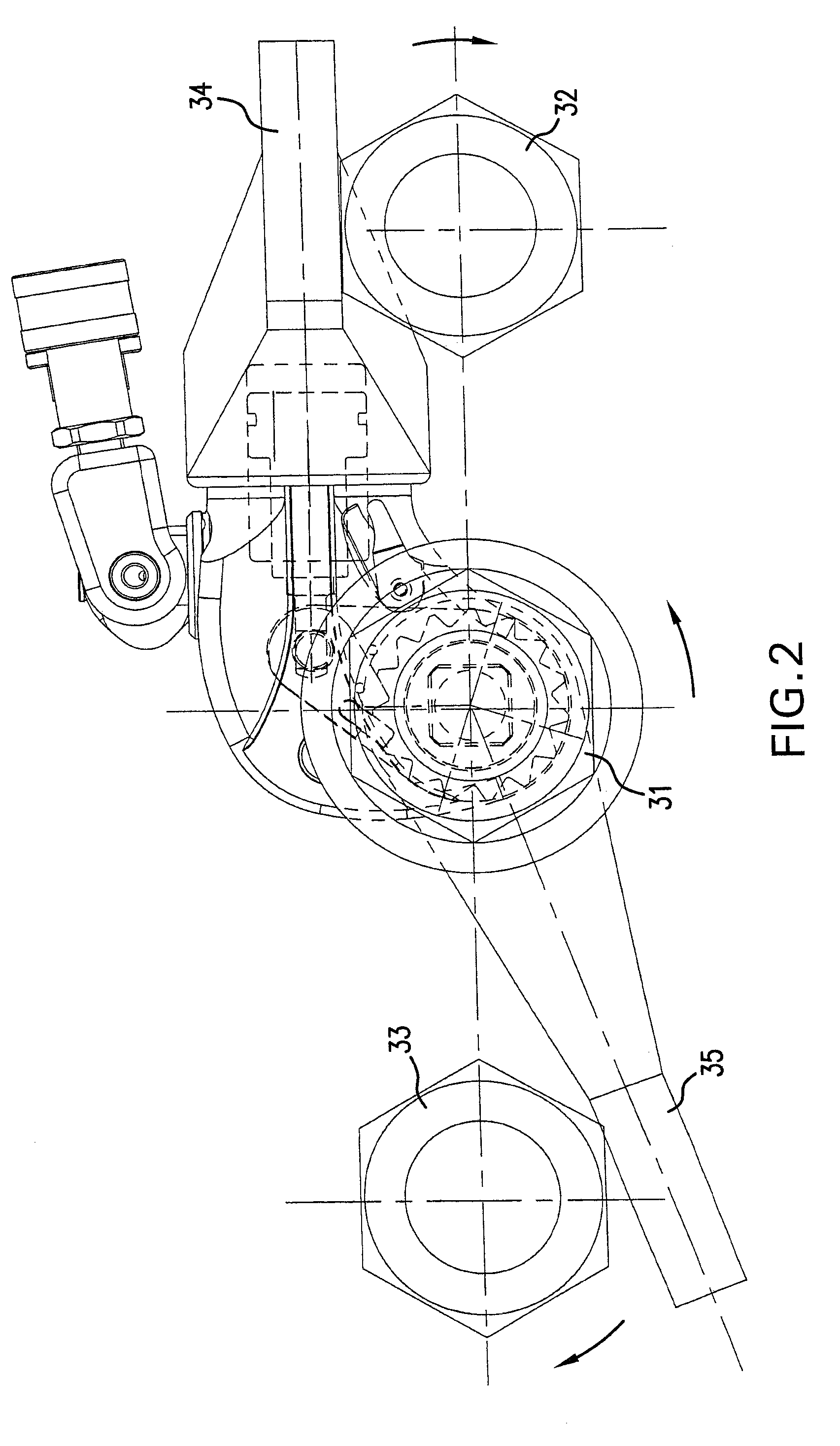

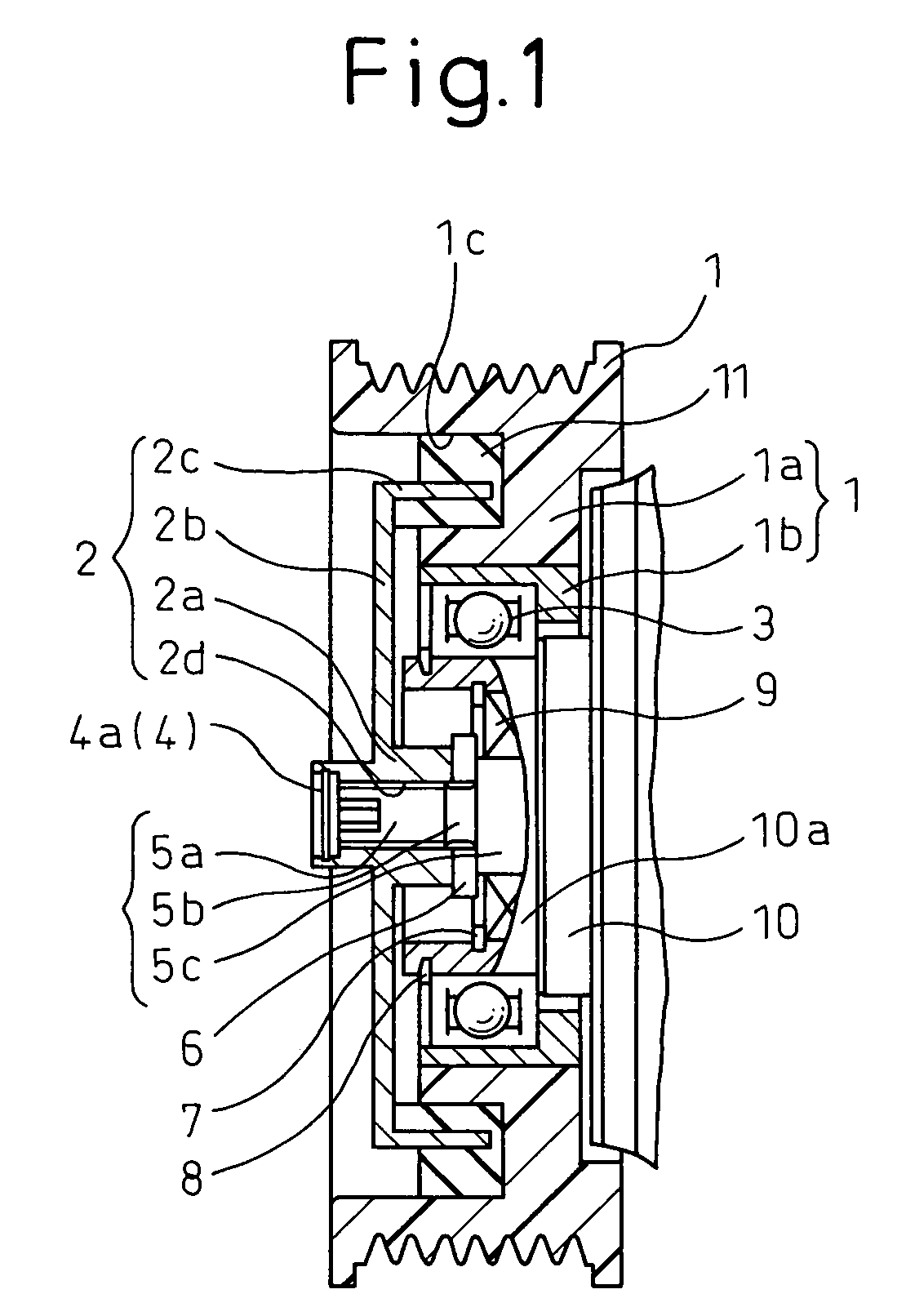

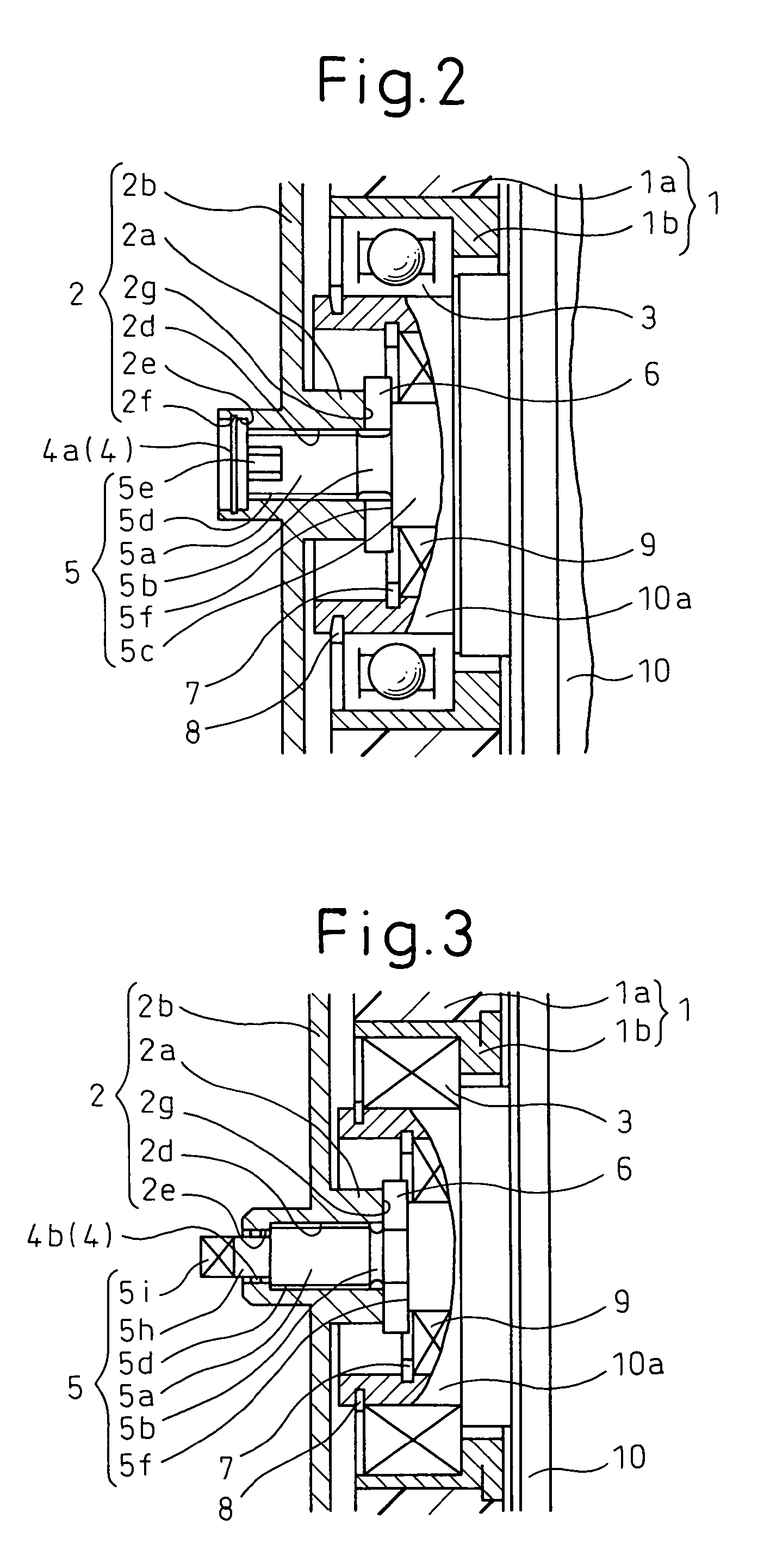

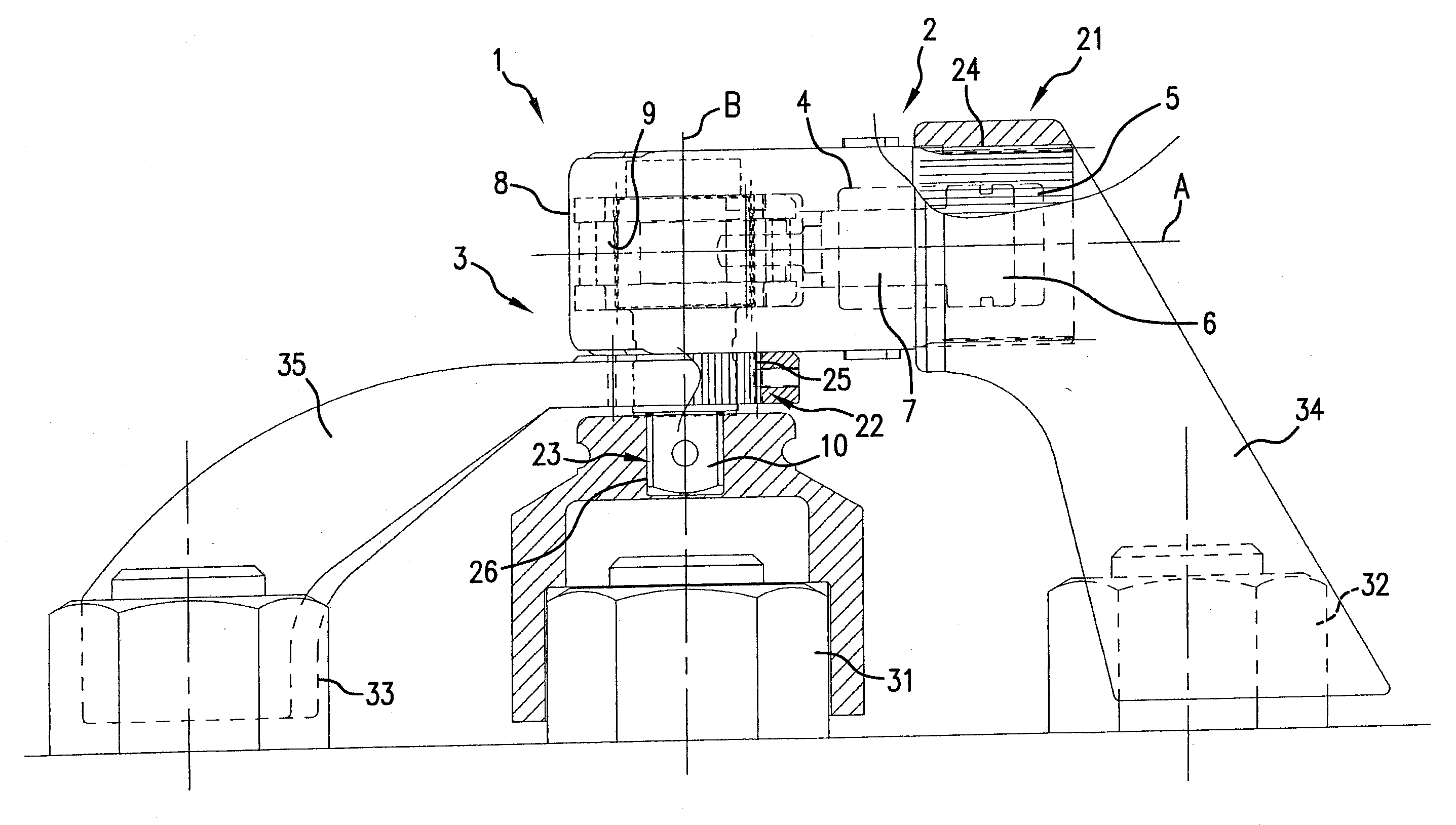

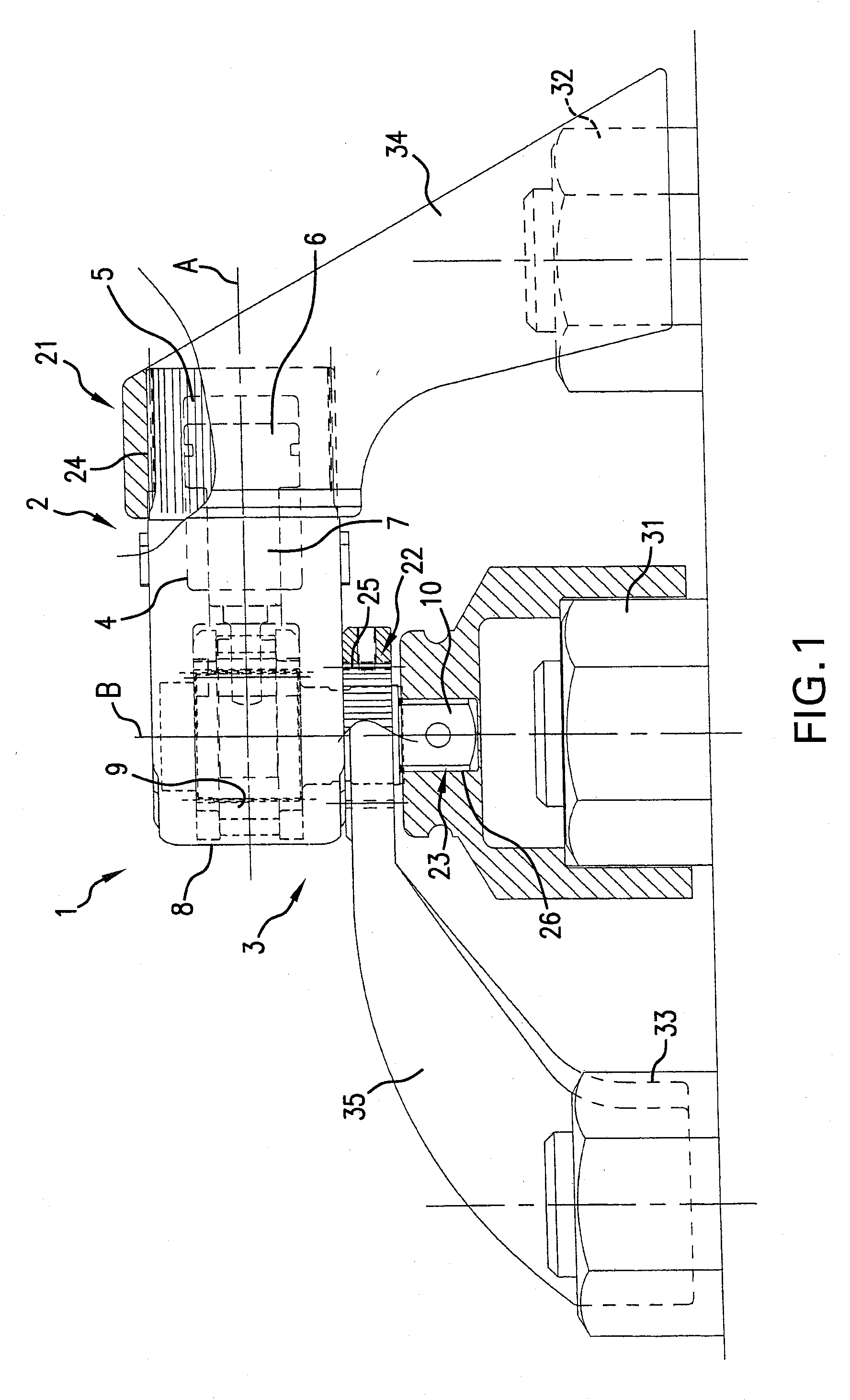

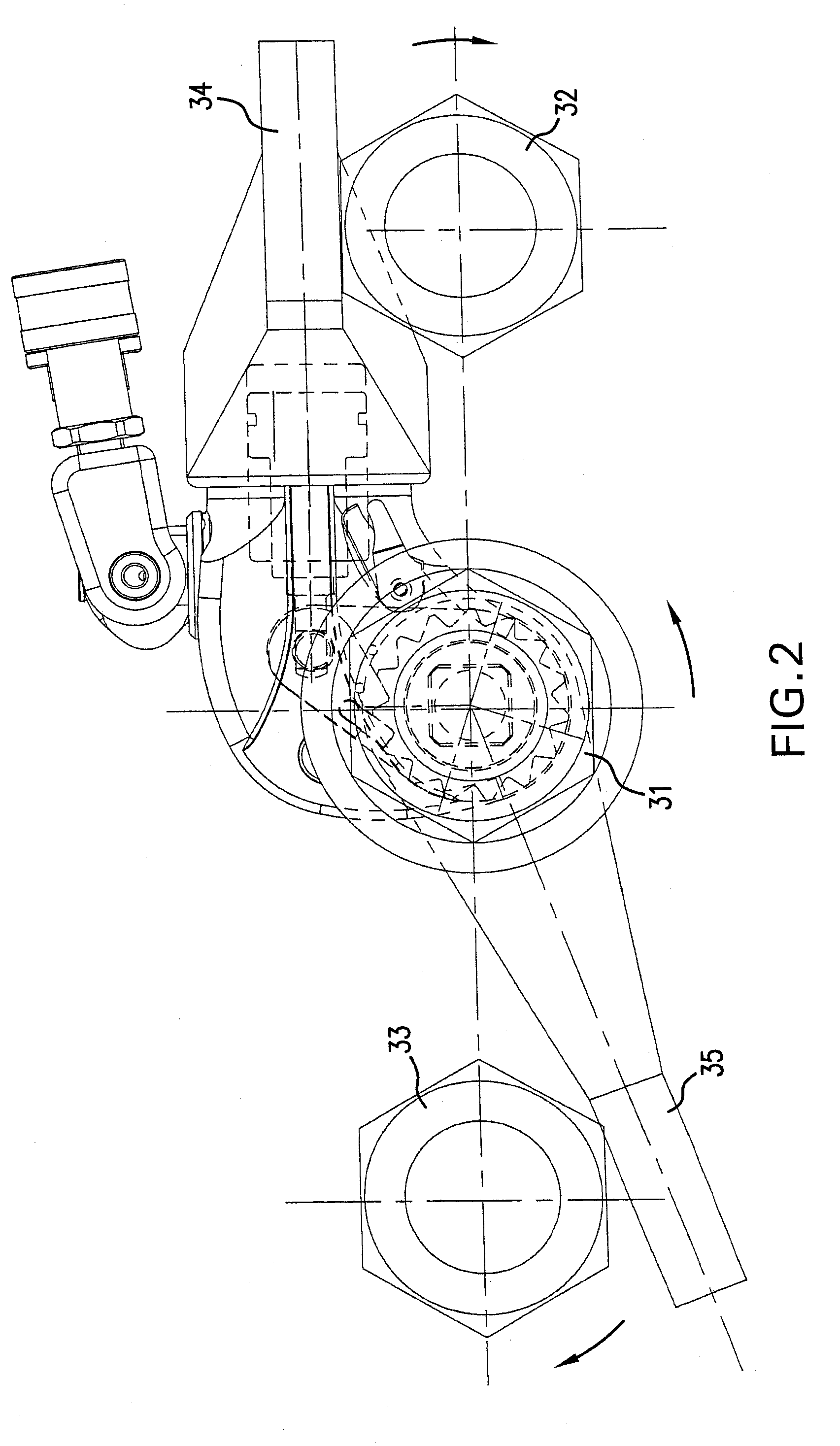

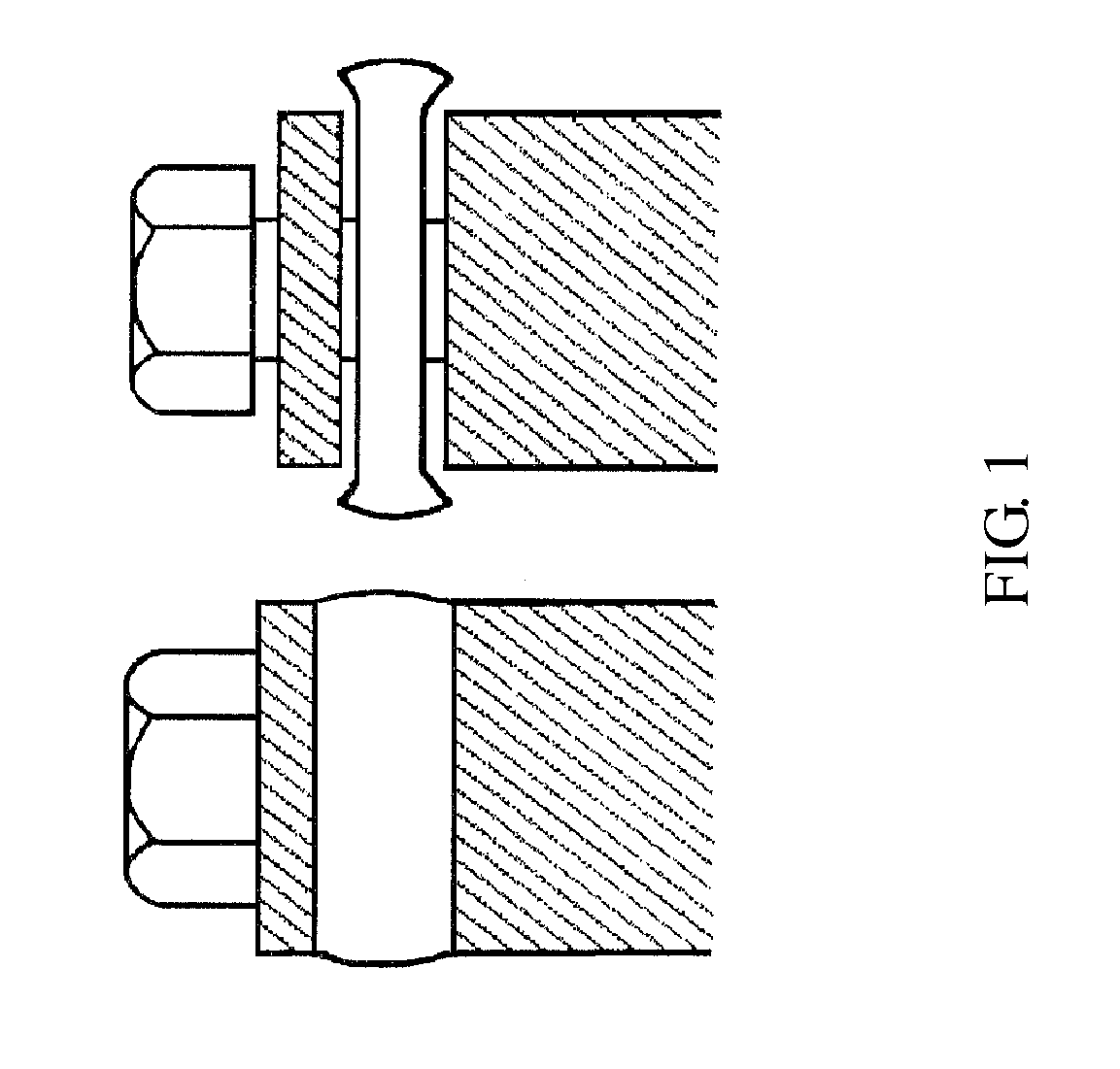

Fluid-operated torque wrench for and method of tightening or loosening fasteners

InactiveUS7765895B2Reduce frictionImproved Torque AccuracySpannersWrenchesEngineeringStationary object

A fluid-operated torque wrench for tightening or loosening a fastener has a housing having two housing portions including a cylinder portion and a driving portion, cylinder-piston means arranged in the cylinder portion and movable along a first axis, a lever-type ratchet mechanism arranged in the driving portion and connected to the cylinder-piston means to be driven by the later, the lever-type ratchet mechanism having a ratchet turnable about a second axis which is perpendicular to the first axis, at least three connecting elements including first and second connecting elements receiving a given turning force acting in one direction during operation of the wrench, and a third connecting element receiving a turning force in an opposite direction during operation of the wrench and being equal to the given turning force acting in the one direction, so that one of the turning forces turns a fastener to be tightened or loosened while another of the turning forces is transferred to a stationary object.

Owner:HYTORC DIV UNEX CORP

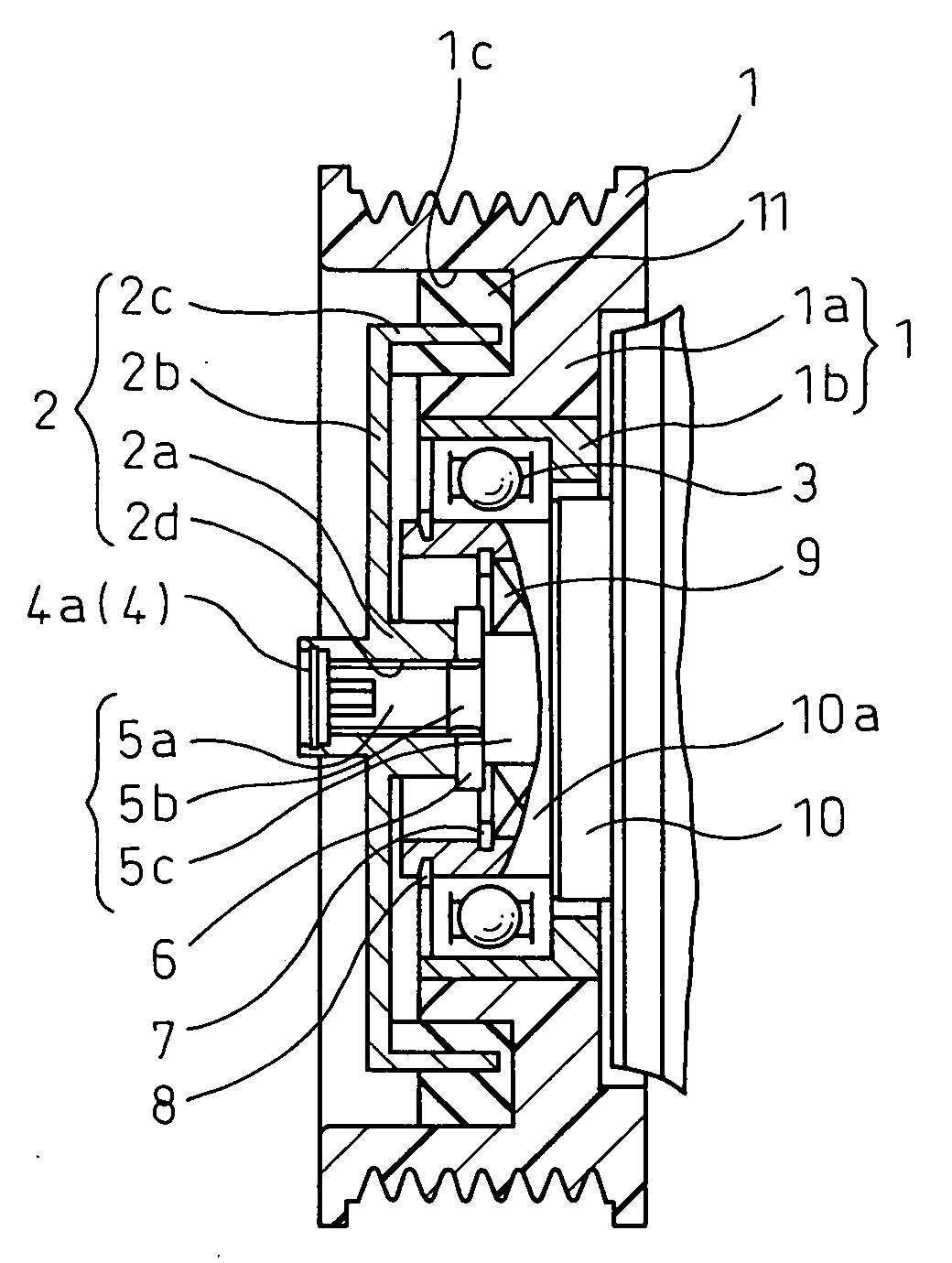

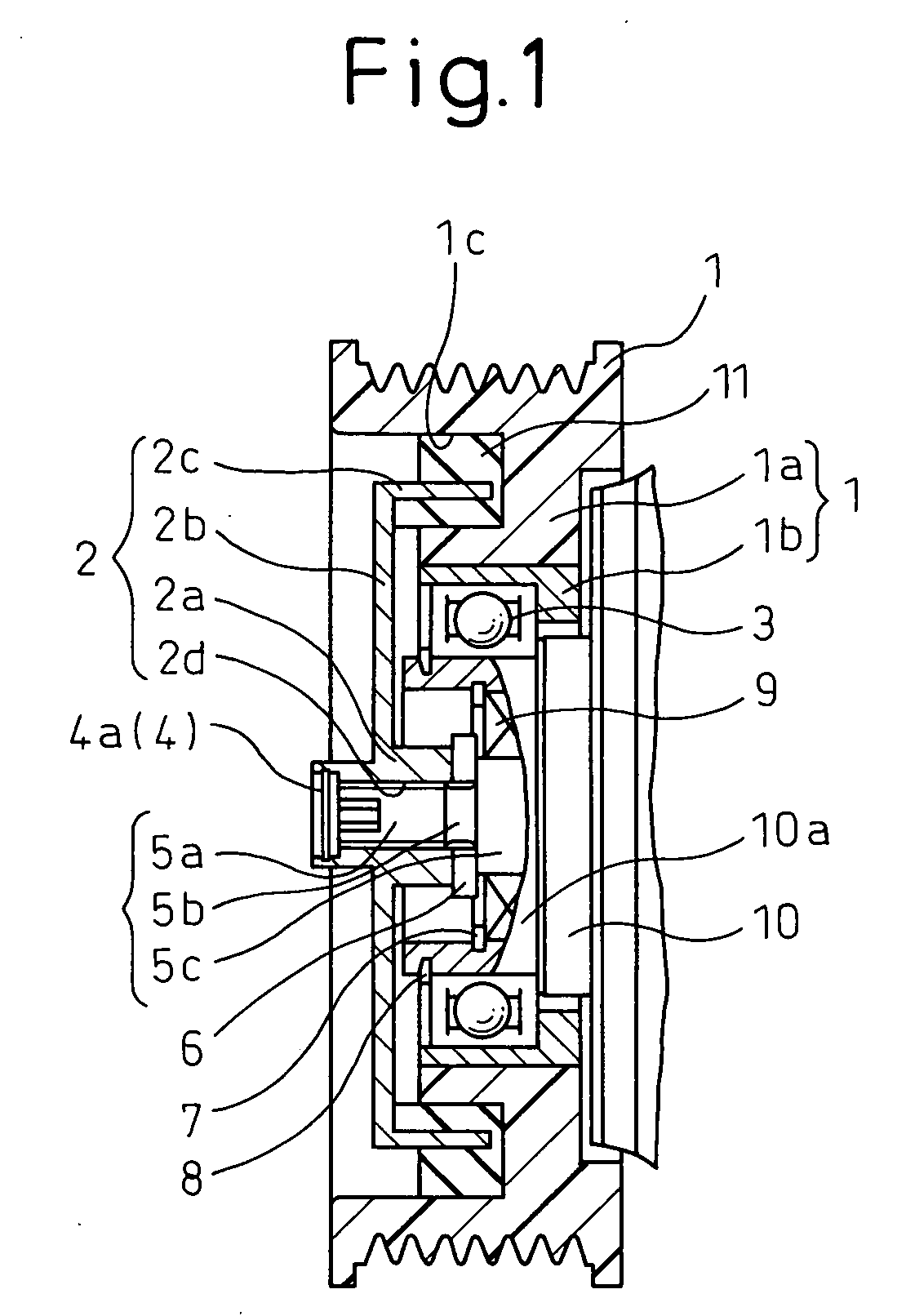

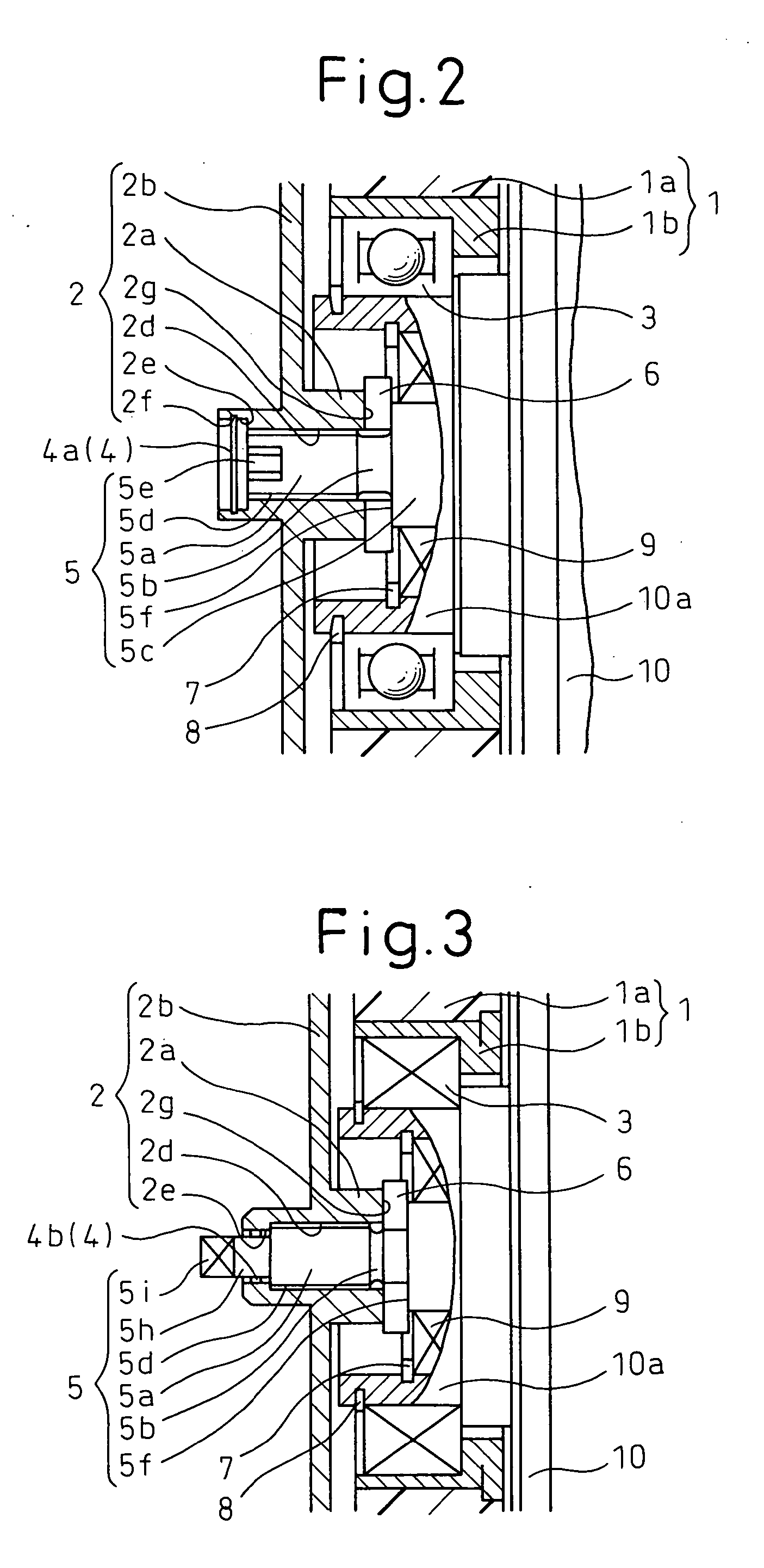

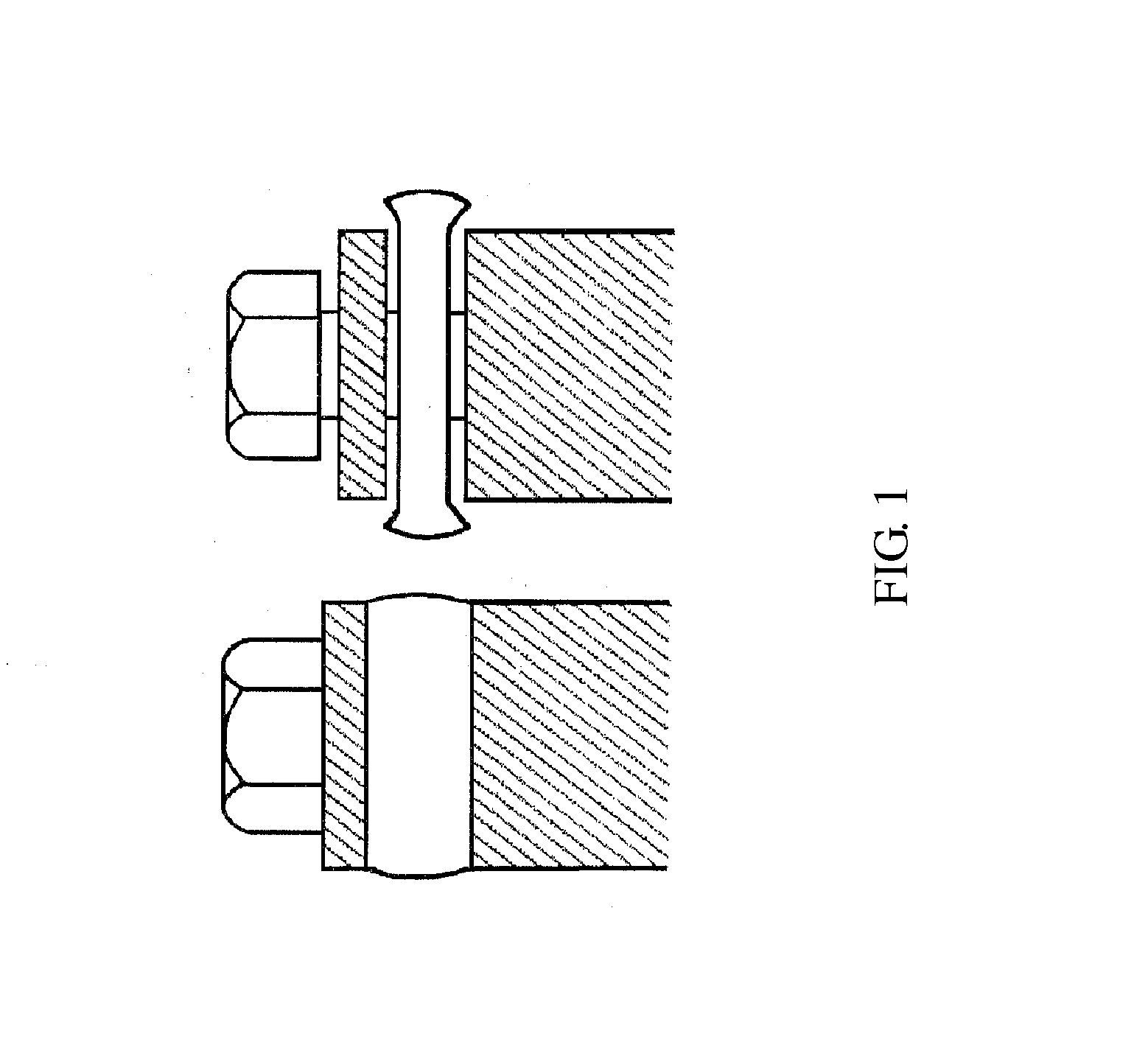

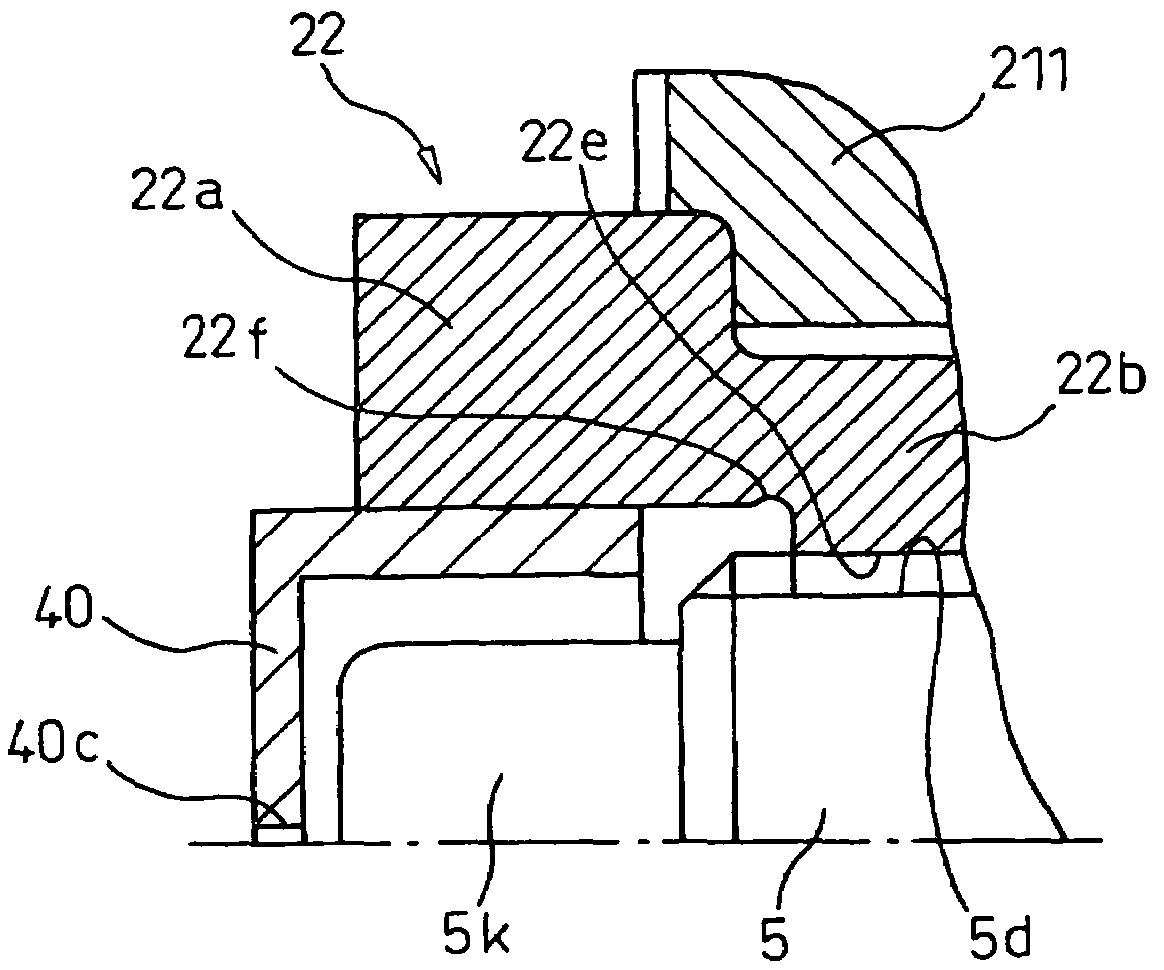

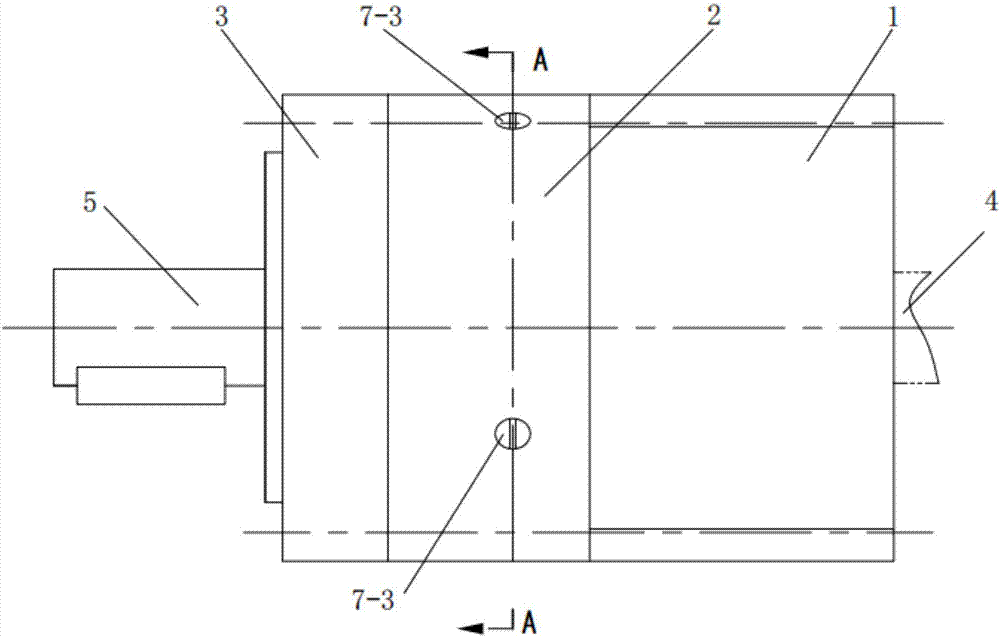

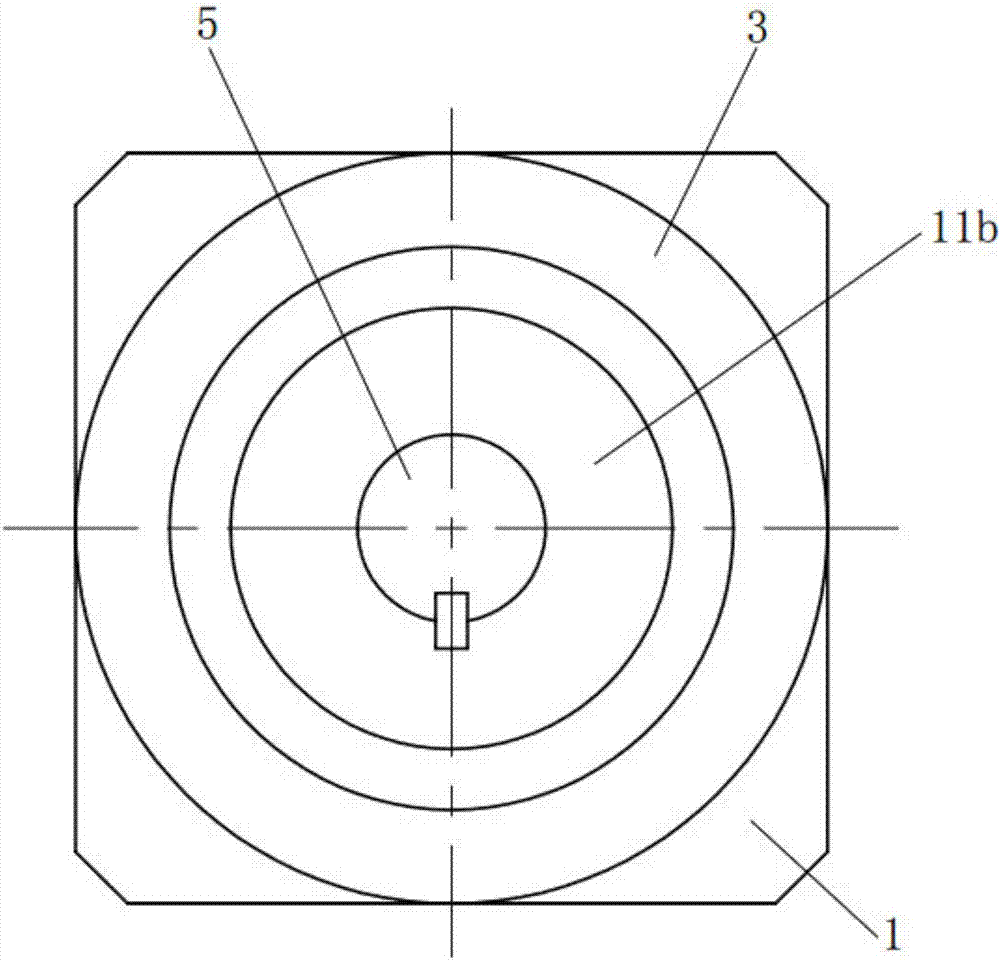

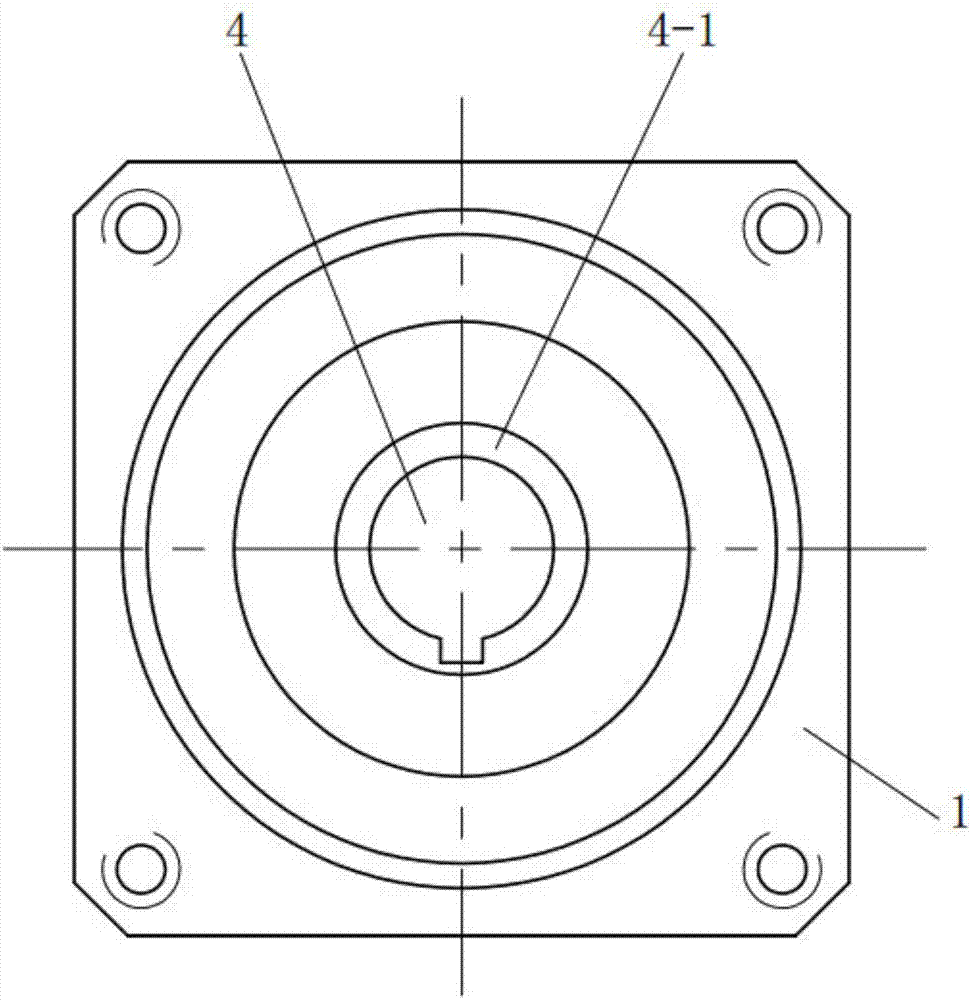

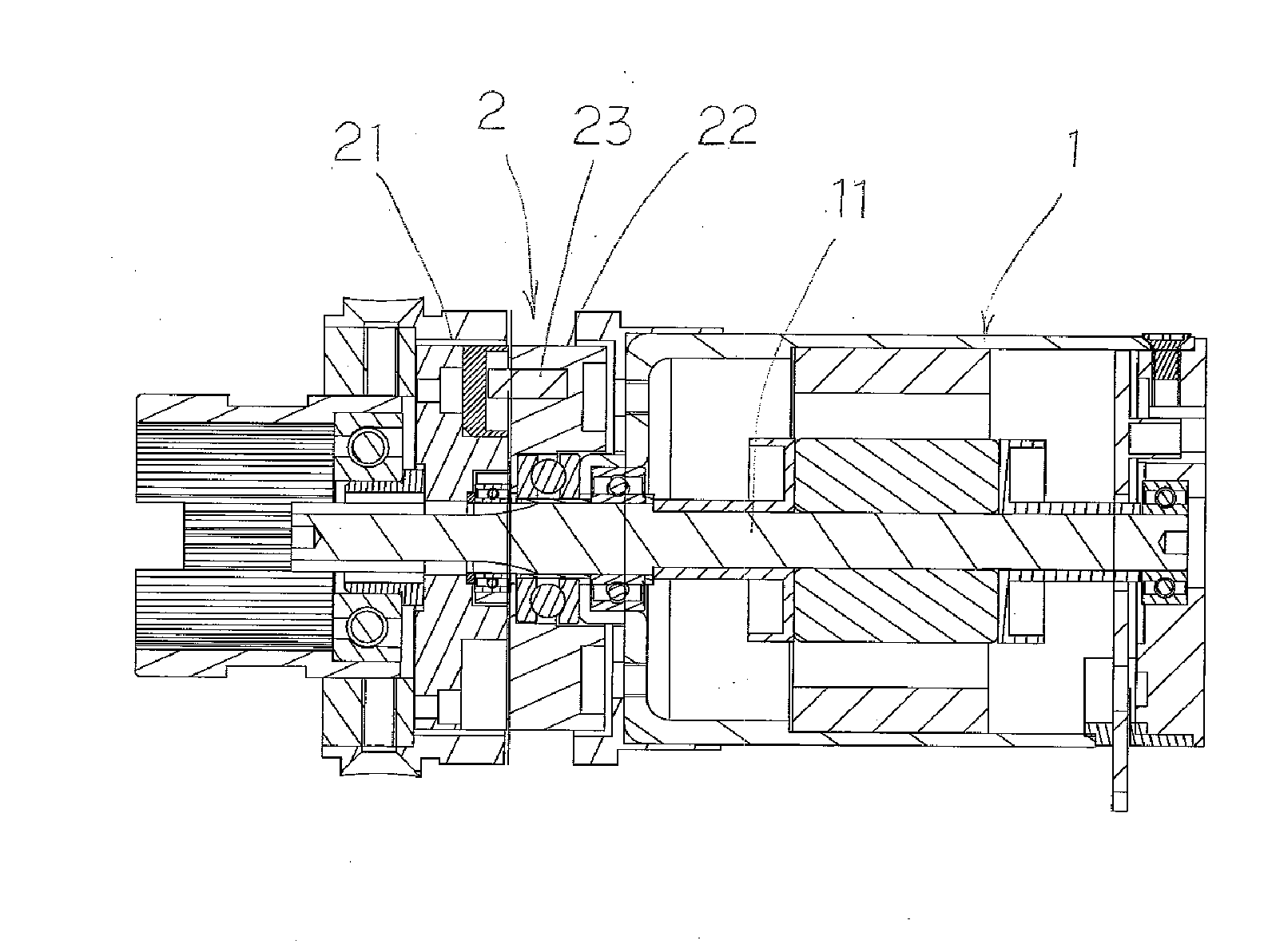

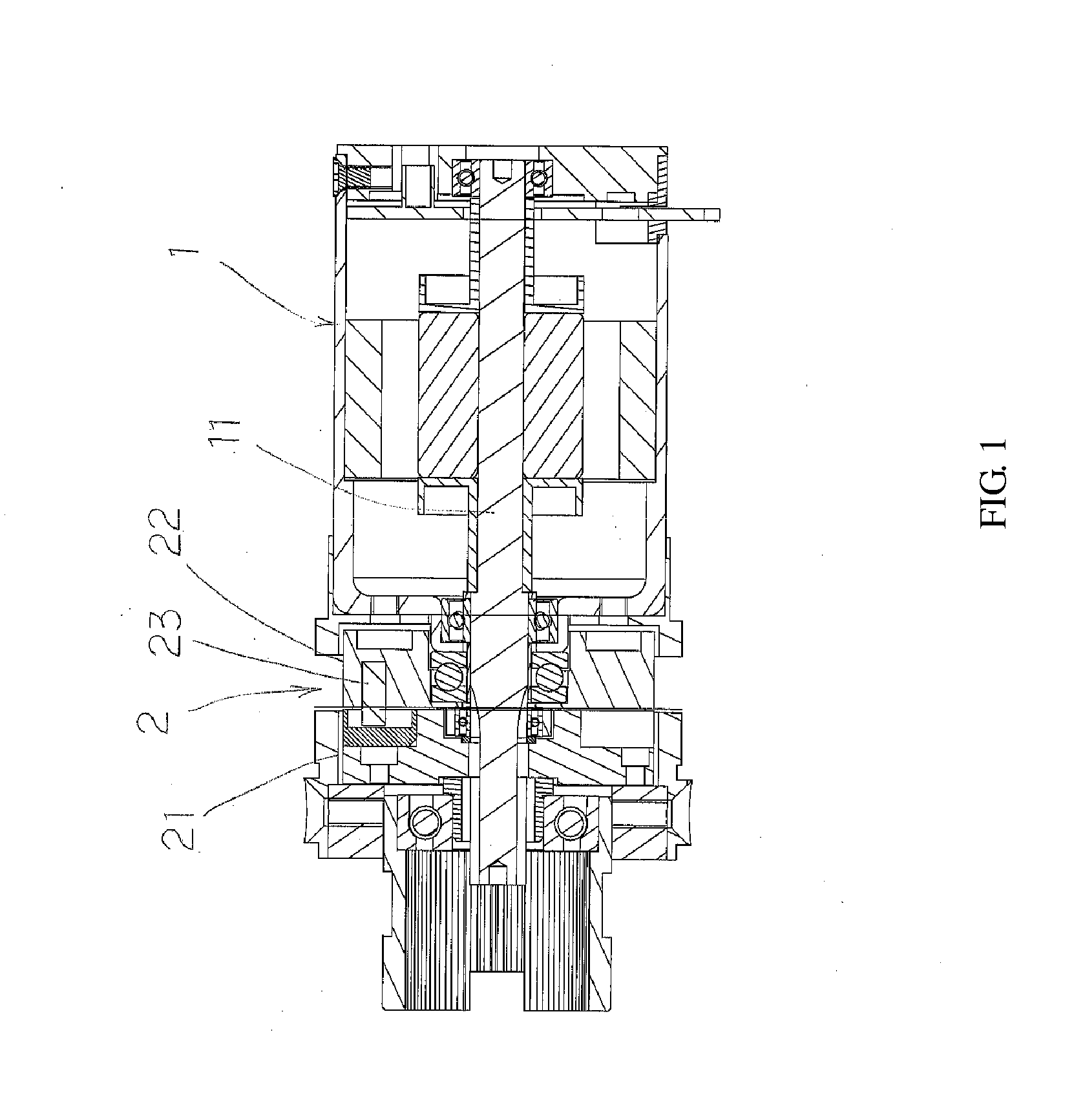

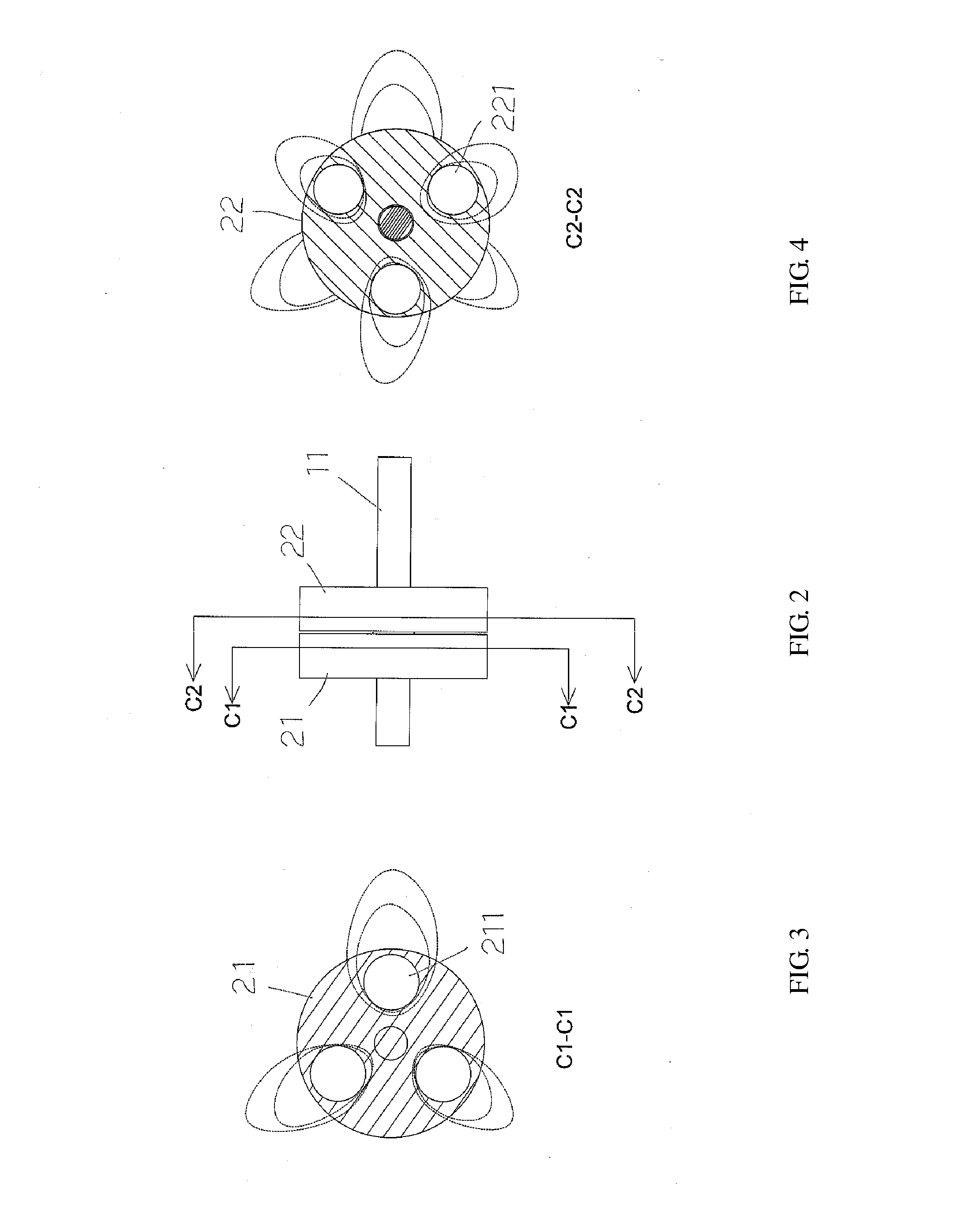

Power transmission device

In the power transmission device having a torque limiting function for shutting off the transmission of an excessively high torque between the pulley 1 and the rotary shaft 5, the hub 2 and the rotary shaft 5 are connected to each other by means of screw engagement between the female screw portion 2d, which is formed on the inner circumferential face of the hub 2, and the male screw portion 5d which is formed on the outer circumferential face of the forward end portion 5a of the rotary shaft 5, and the seal means 4 for sealing between the hub and the rotary shaft is provided adjacent to the front face or the front and rear faces of the screw engaging portion. The torque limiting function may be provided on the rotary shaft side or the hub side.

Owner:DENSO CORP

Method for estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission

ActiveUS9097342B2Avoid damageAccurate estimateAnalogue computers for trafficGearing controlHydraulic machineryControl theory

The method of estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission uses pressure data and other metrics of a hydrostatic power unit of the transmission in lieu of actual driveline torque data. A mechanical efficiency of the transmission is determined as a function of whether the power unit is operating in a power generation or regeneration mode, and the torque output of the power unit is estimated from that and other hydrostatic parameters. This is used to estimate a torque output of a planetary power unit of the transmission, and the torque on an output member of the driveline is then estimated using that value, and appropriate corrective action taken.

Owner:BLUE LEAF I P INC

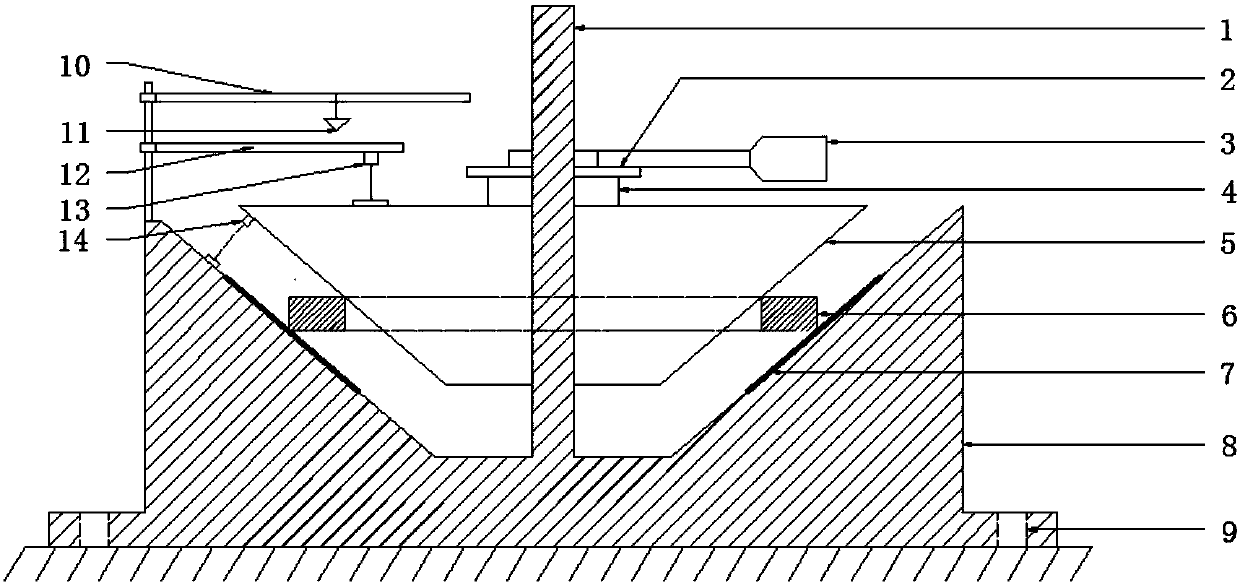

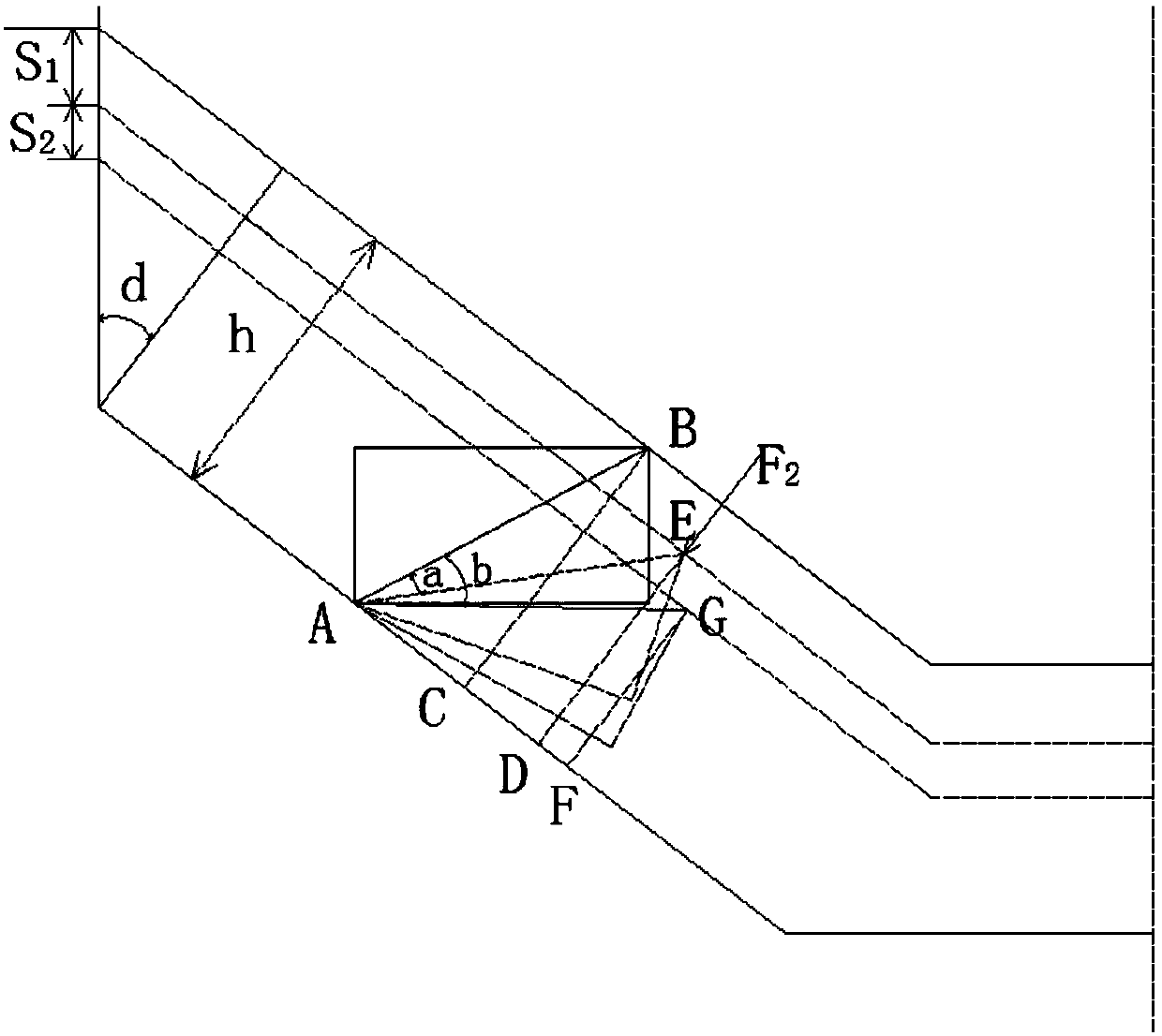

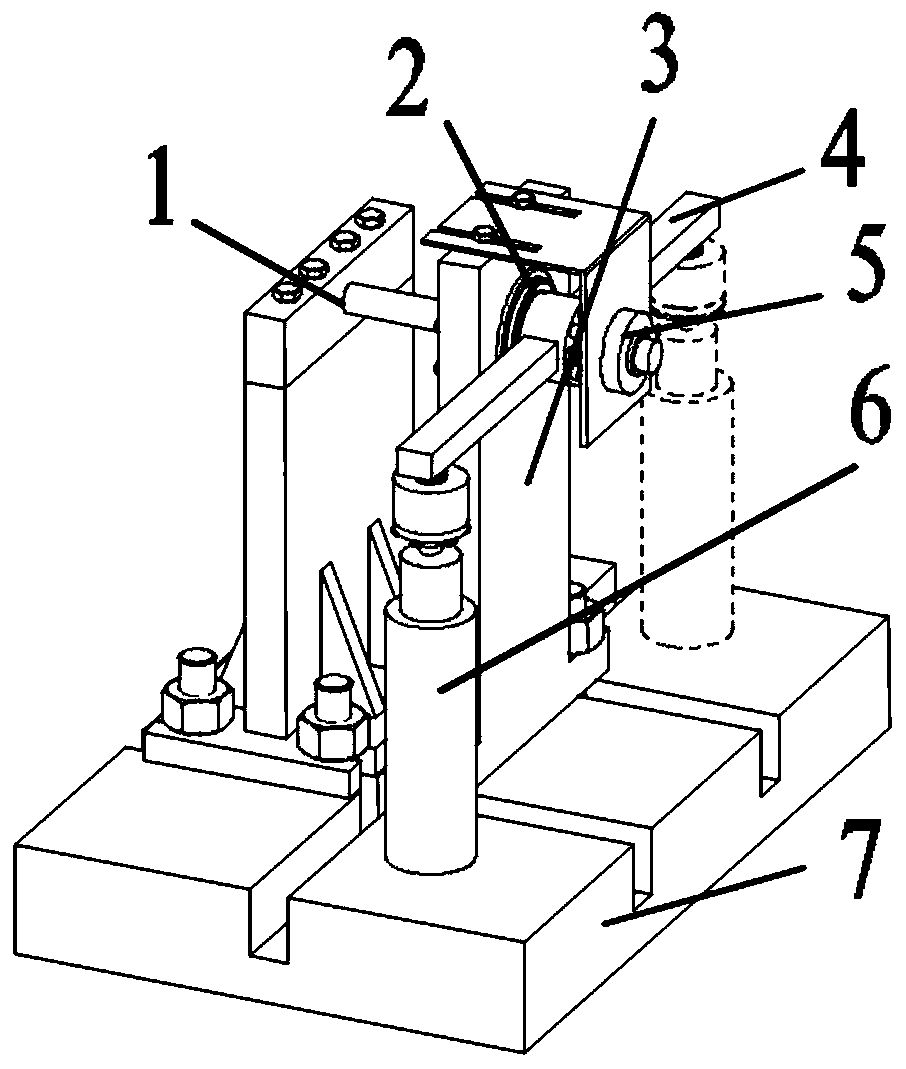

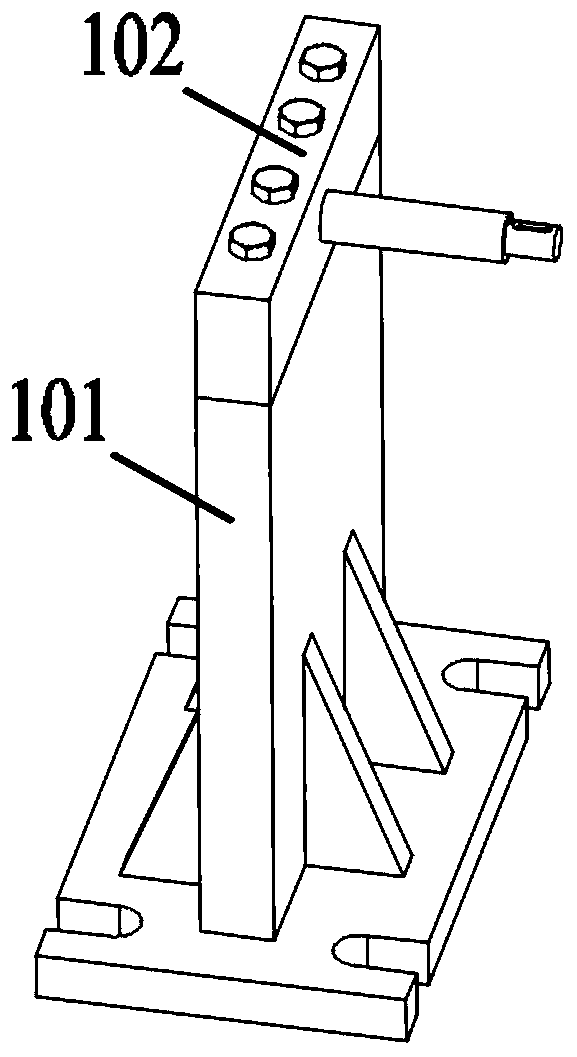

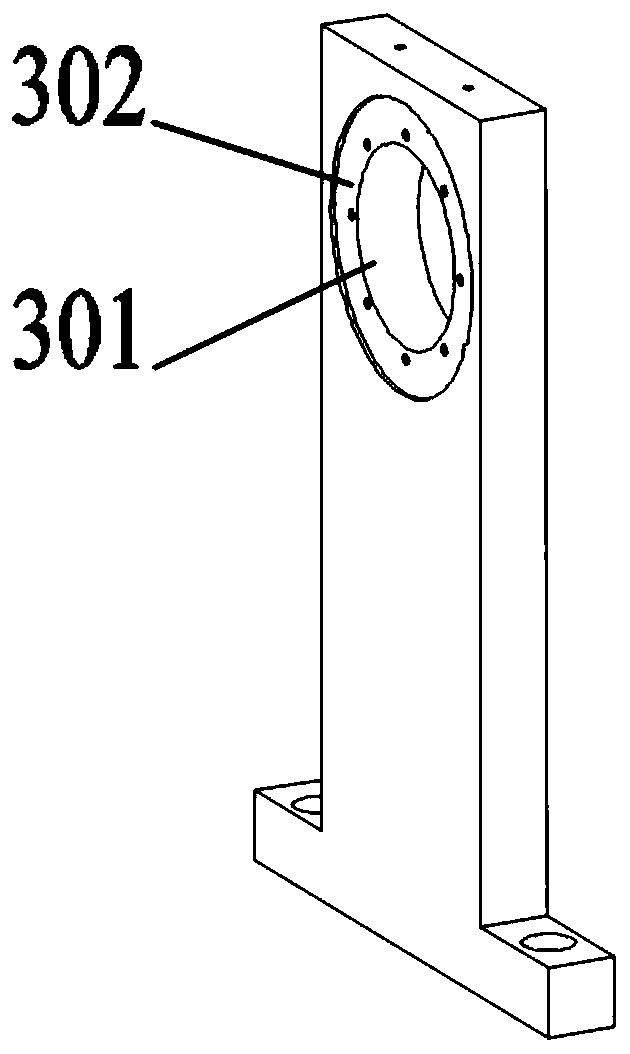

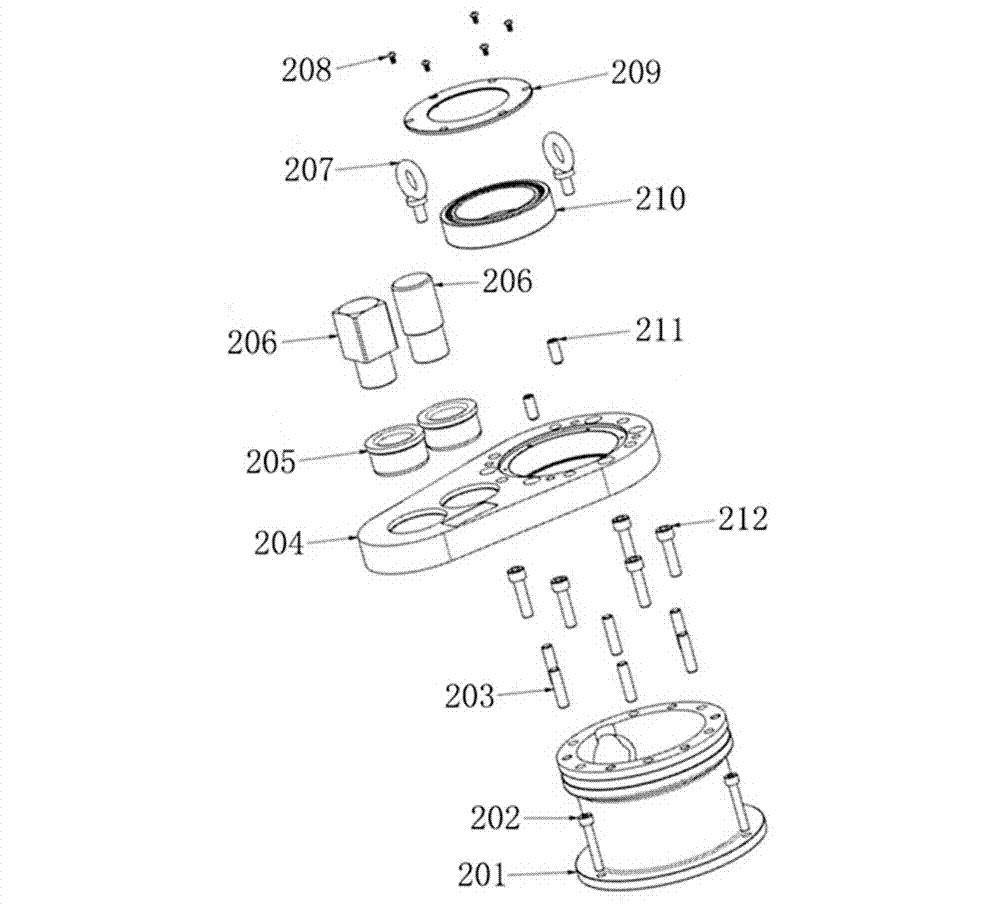

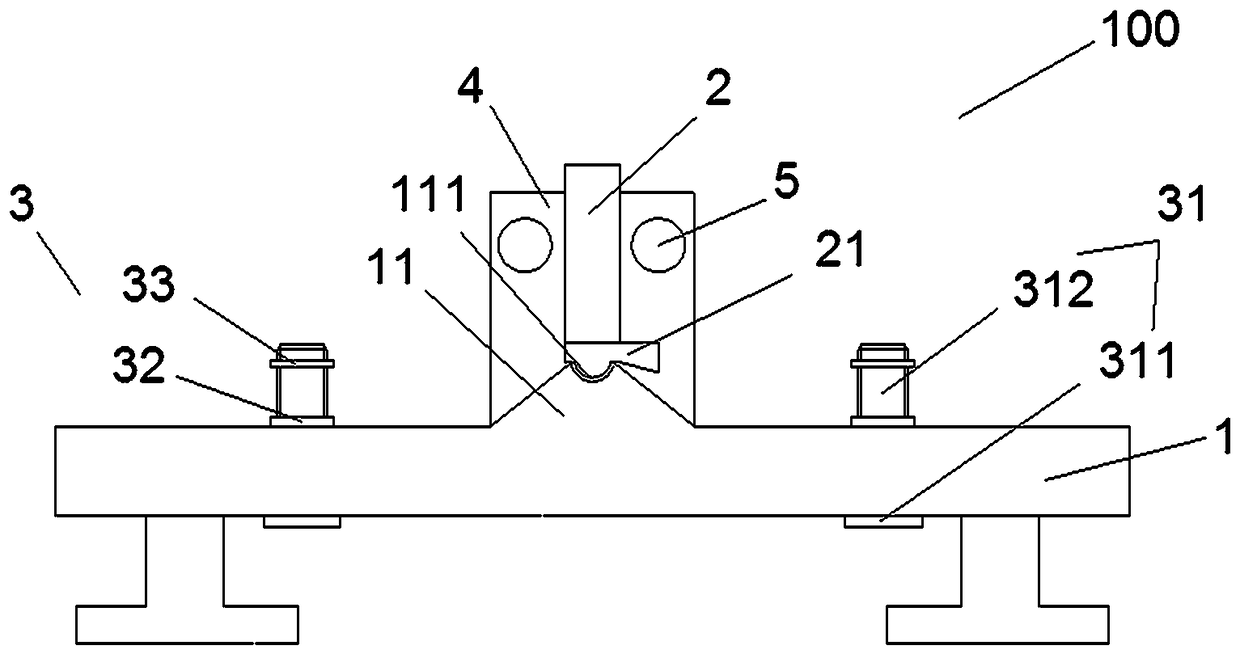

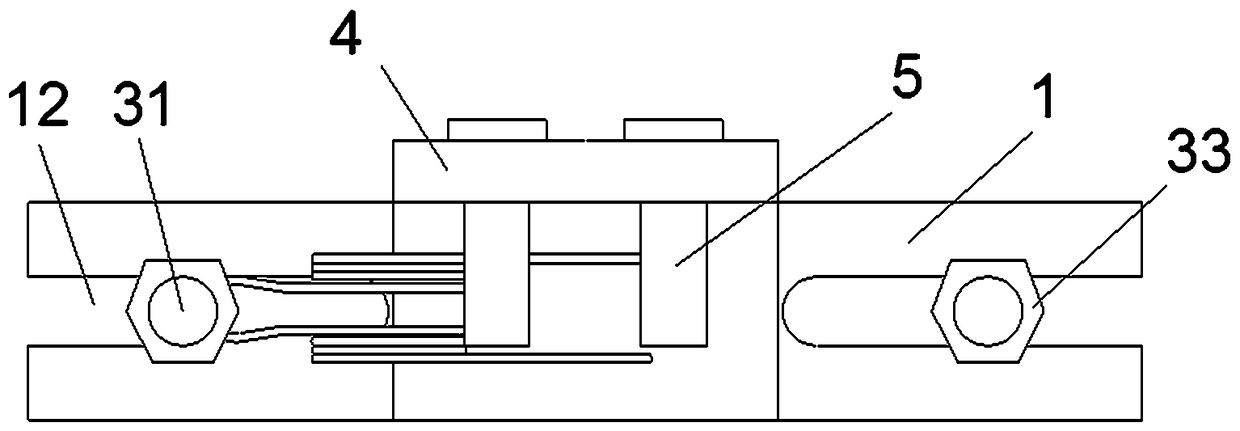

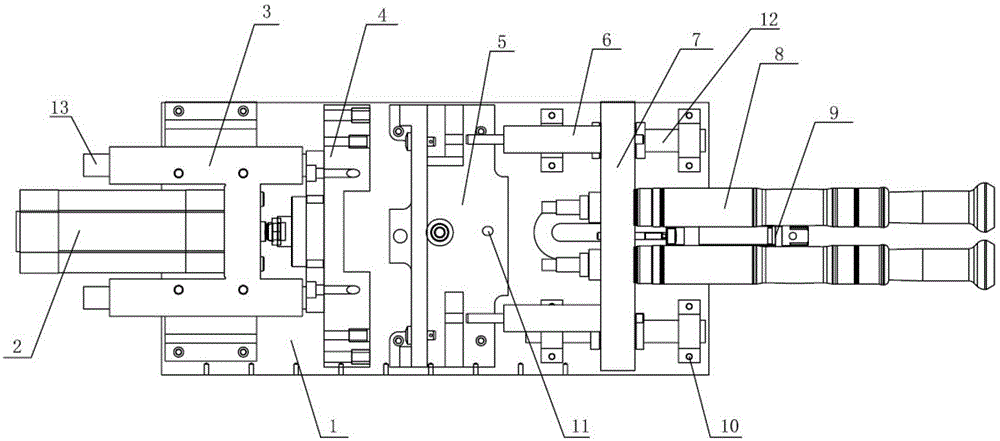

Testing apparatus and method for testing torsional rigidity of radial section of piston ring

ActiveCN107677558AImproved Torque AccuracyEasy to fixMaterial strength using steady torsional forcesPiston ringMechanical engineering

The invention specifically provides a testing apparatus for testing the torsional rigidity of the radial section of a piston ring, belonging to the field of power machinery. The testing apparatus comprises the piston ring, a base, a pressing body, a force sensor, a loading handle, a leveling swing rod, a plumb, a displacement measuring swing rod, a first displacement sensor and a second displacement sensor, wherein a groove is arranged on the base, and a central column is arranged at the center of the groove on the base; the loading handle, the force sensor and the pressing body are sequentially arranged on the central column from top to bottom; the piston ring is arranged between the side surface of the pressing body and the inner wall of the groove on the base; the circumferential section of the piston ring is perpendicular to the central column; the top of the base is provided with a connecting rod which is provided with the leveling swing rod and the displacement measuring swing rod; the first displacement sensor is installed between the displacement measurement swing rod and the upper surface of the pressing body; and the second displacement sensor is installed between the side surface of the pressing body and the inner wall of the groove on the base. According to the invention, the radial section deformation of the piston ring is taken into consideration, so the precisionof torque determination of the piston ring is high, and accurate torsional rigidity of the radial section of the piston ring can be obtained.

Owner:HARBIN ENG UNIV

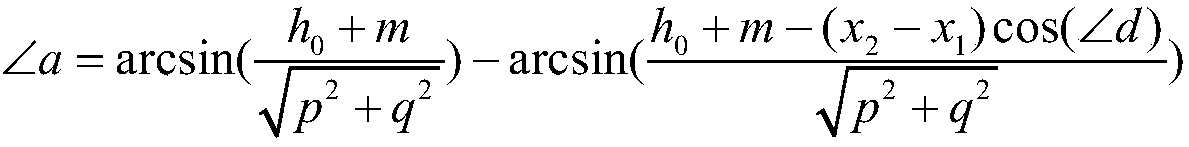

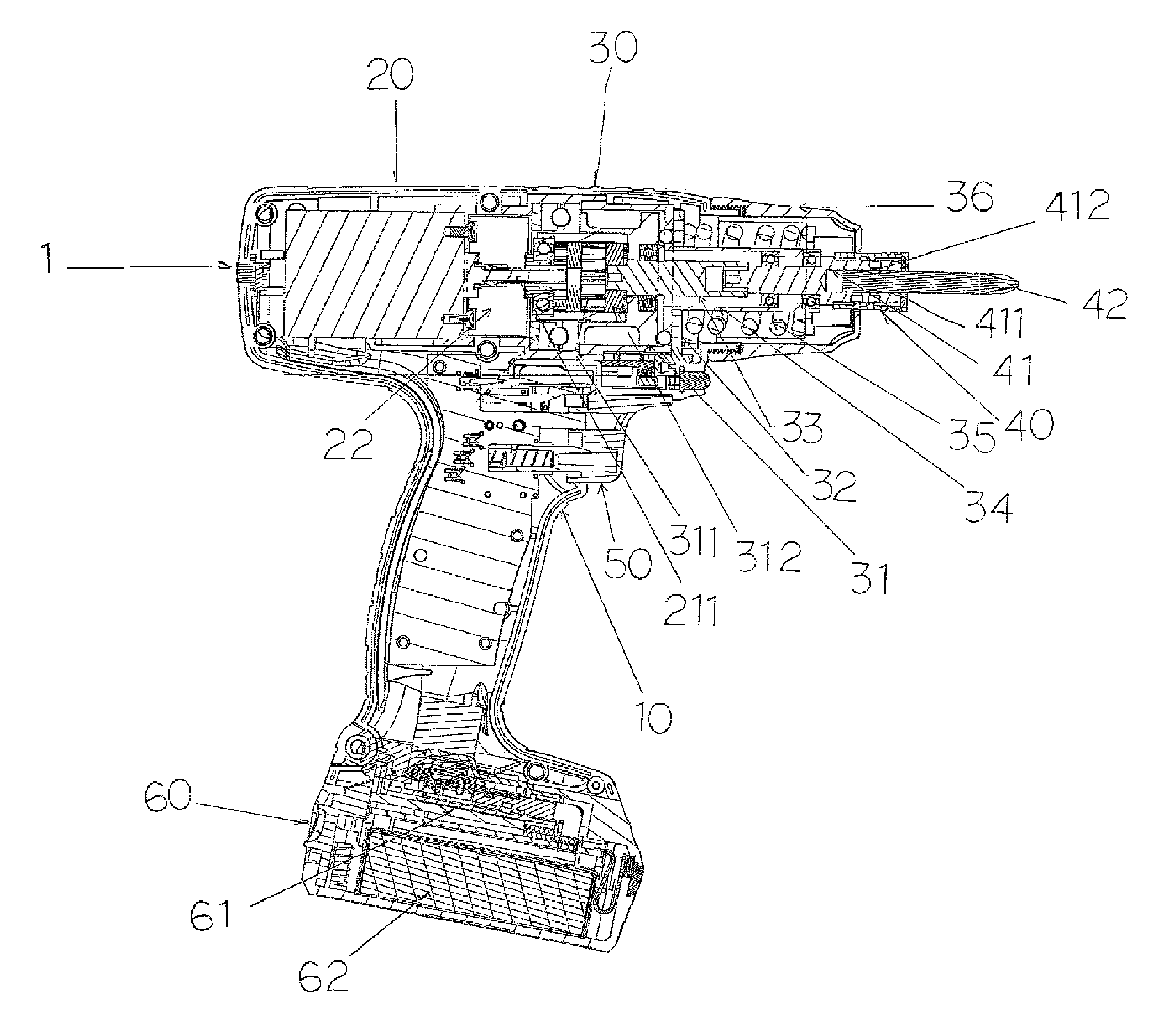

Two-stage locking electric screwdriver

ActiveUS20150352698A1Improved Torque AccuracySpannersPortable power-driven toolsElectric machineTorsion spring

A two-stage locking electric screwdriver, with its main improved features as follow: the electric screwdriver has pre-locking and locking functions; the torque settings of the electric screwdriver can be easily modulated, and meanwhile the torque accuracy and energy efficiency can be improved; the torque modulation type is external modulation, so that the torque modulation can be carried out externally and even the torsion spring can be replaced. Meanwhile, the component structures inside the electric screwdriver is improved through a design that the motor directly drives the clutch and then drive the screwdriver head unit, and that an internal gear clutch is used to replaced the gear unit and clutch unit, so that the number of parts is dramatically reduced to save production cost. During general rotation, the electric screwdriver will not drive the clutch unit, and when the torque jumps to the set value, the internal gear clutch rotates and generates a torque.

Owner:HSU HSIU LIN

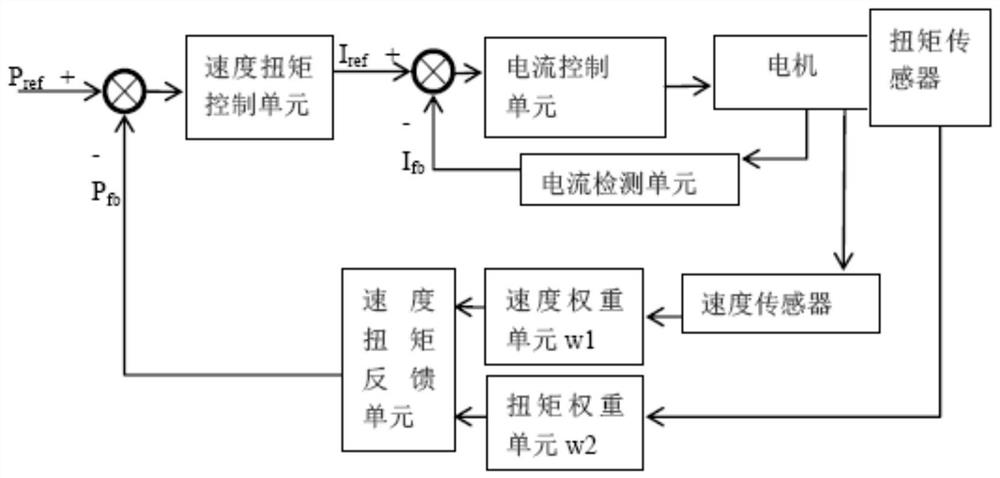

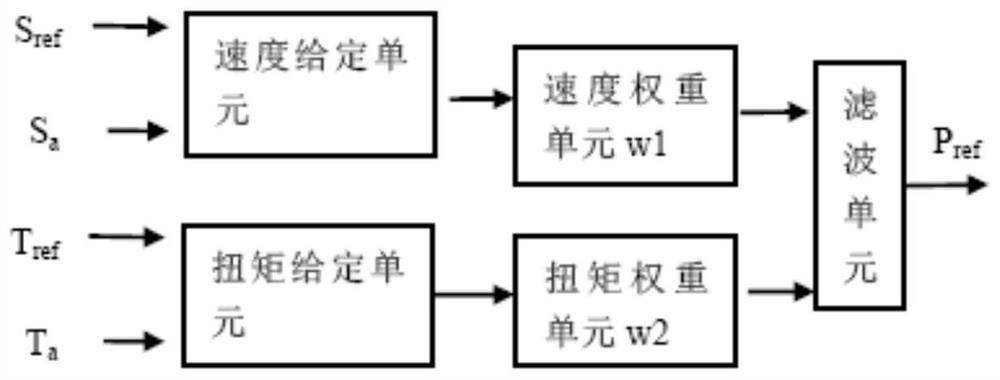

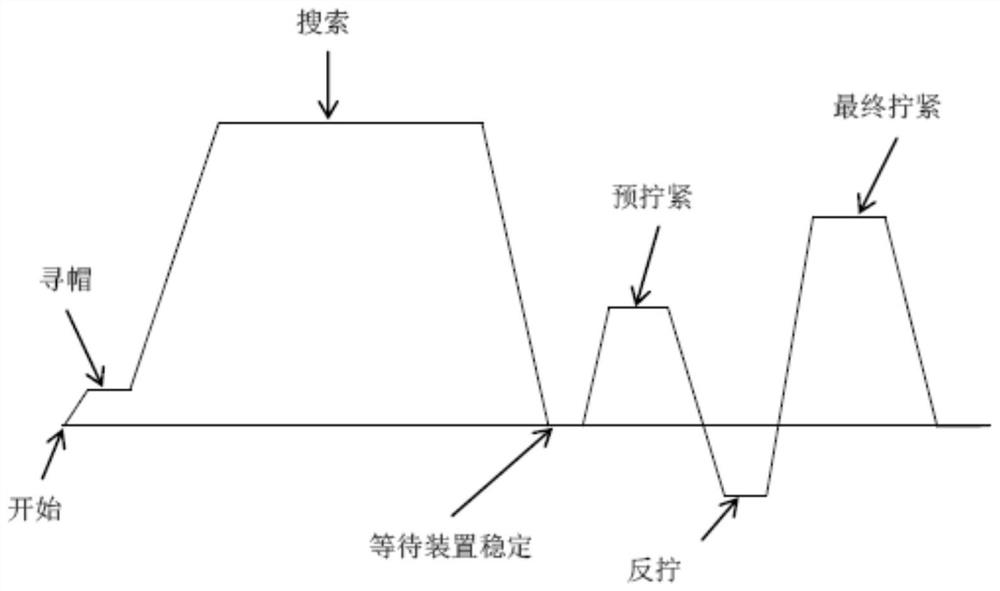

Screw fastening system and method

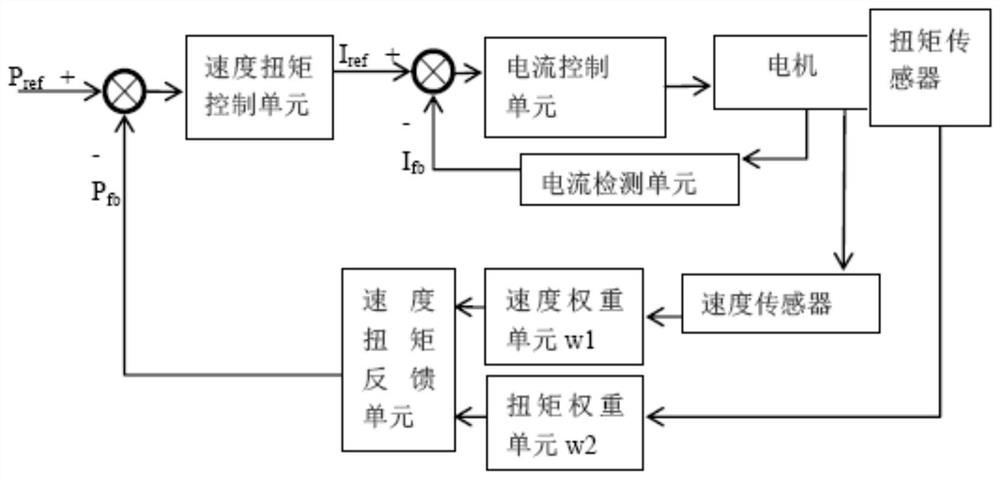

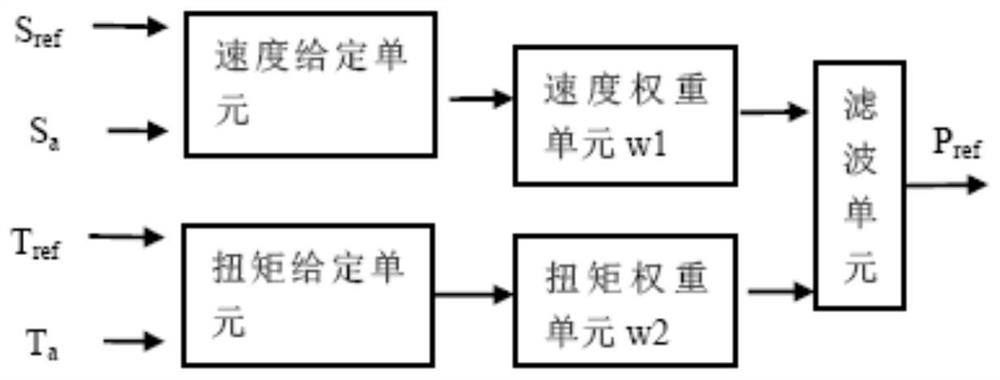

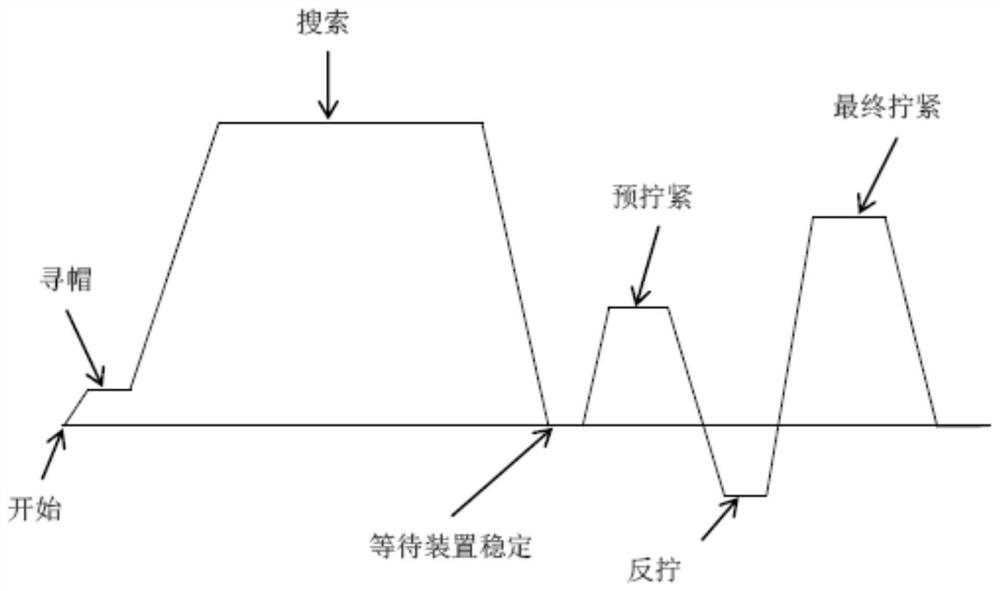

ActiveCN112536754AImprove tightening effectReduce shock torqueElectric motor controlSpannersMotor speedControl engineering

The invention discloses a screw fastening system and method. The screw fastening system comprises a speed giving unit, a torque giving unit, a filtering unit, a speed torque control unit, a speed torque feedback unit, a current control unit, a speed weight unit, a torque weight unit, a motor, a current detection unit, a speed sensor, and a torque sensor; an electric wrench is connected to one endof the motor; the input end of the speed sensor, the input end of the torque sensor and the input end of the current detection unit are respectively connected with the motor; the output end of the current detection unit is connected with the current control unit and provides a current feedback value for the current control unit; the speed torque control unit is connected with the current control unit; and the current control unit is connected with the motor. According to the screw fastening system and method, by arranging the speed torque control unit, the speed torque feedback unit and the current control unit, the construction torque of the to-be-fastened screw and the rotating speed of the motor are controlled at the same time, so that the impact torque is reduced, higher torque precision is guaranteed, and the screw tightening effect is effectively improved.

Owner:GOOGOL PARADOX (DONGGUAN) INTELLIGENT TECH CO LTD

Power transmission device

In the power transmission device having a torque limiting function for shutting off the transmission of an excessively high torque between the pulley 1 and the rotary shaft 5, the hub 2 and the rotary shaft 5 are connected to each other by means of screw engagement between the female screw portion 2d, which is formed on the inner circumferential face of the hub 2, and the male screw portion 5d which is formed on the outer circumferential face of the forward end portion 5a of the rotary shaft 5, and the seal means 4 for sealing between the hub and the rotary shaft is provided adjacent to the front face or the front and rear faces of the screw engaging portion. The torque limiting function may be provided on the rotary shaft side or the hub side.

Owner:DENSO CORP

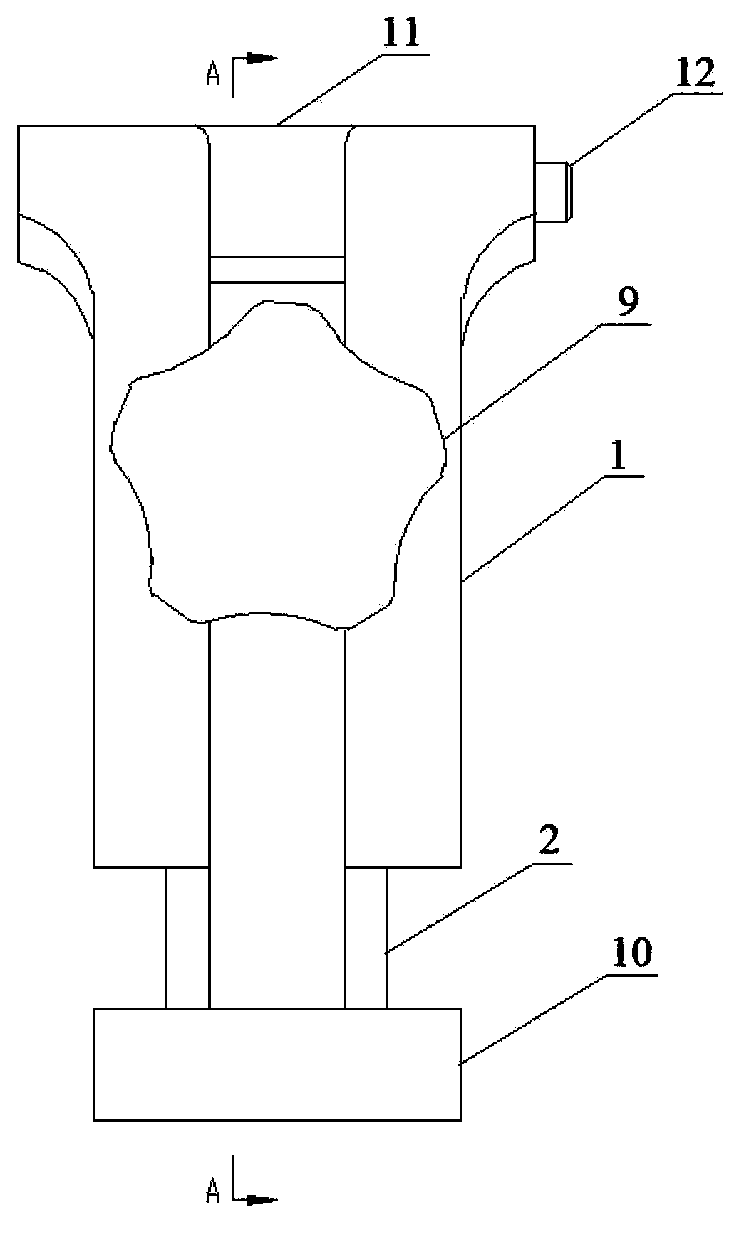

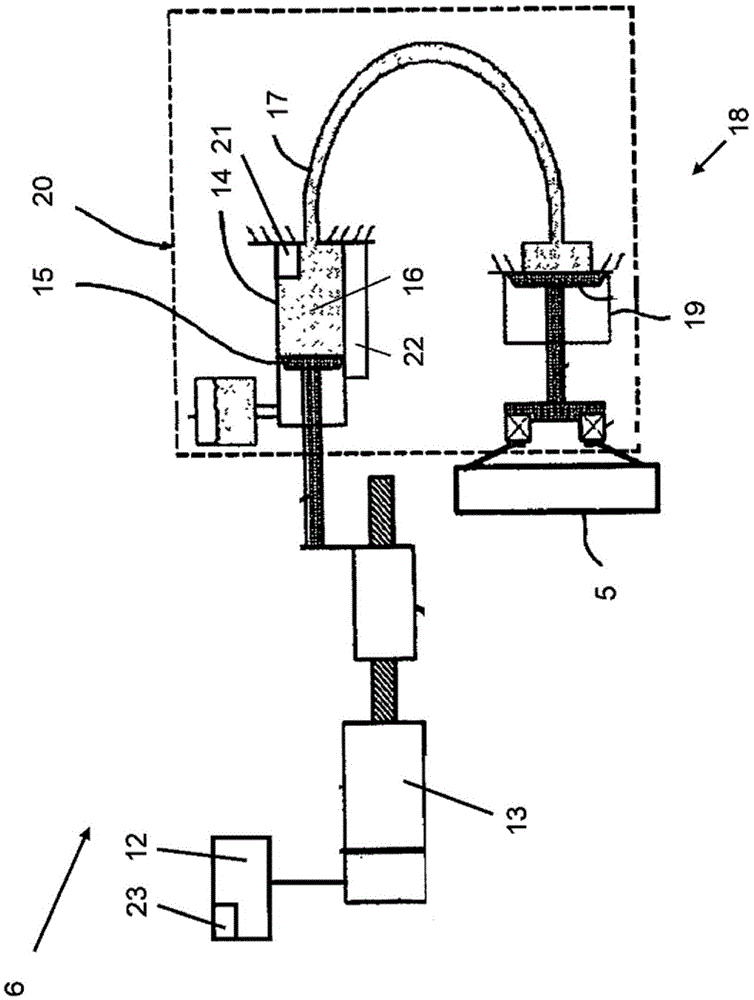

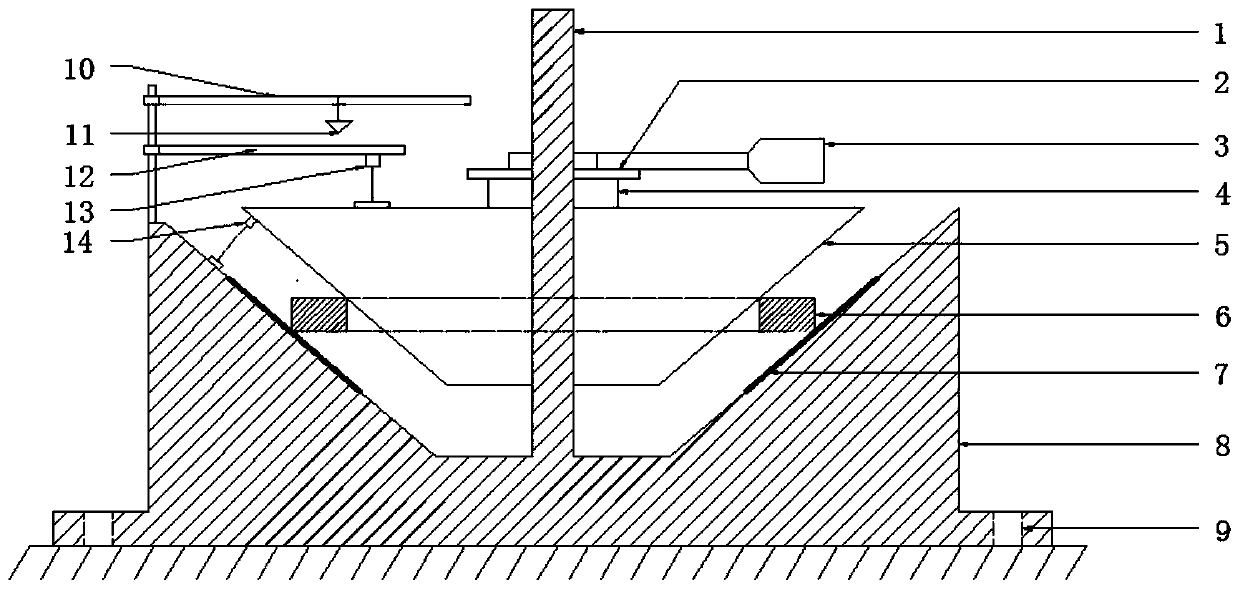

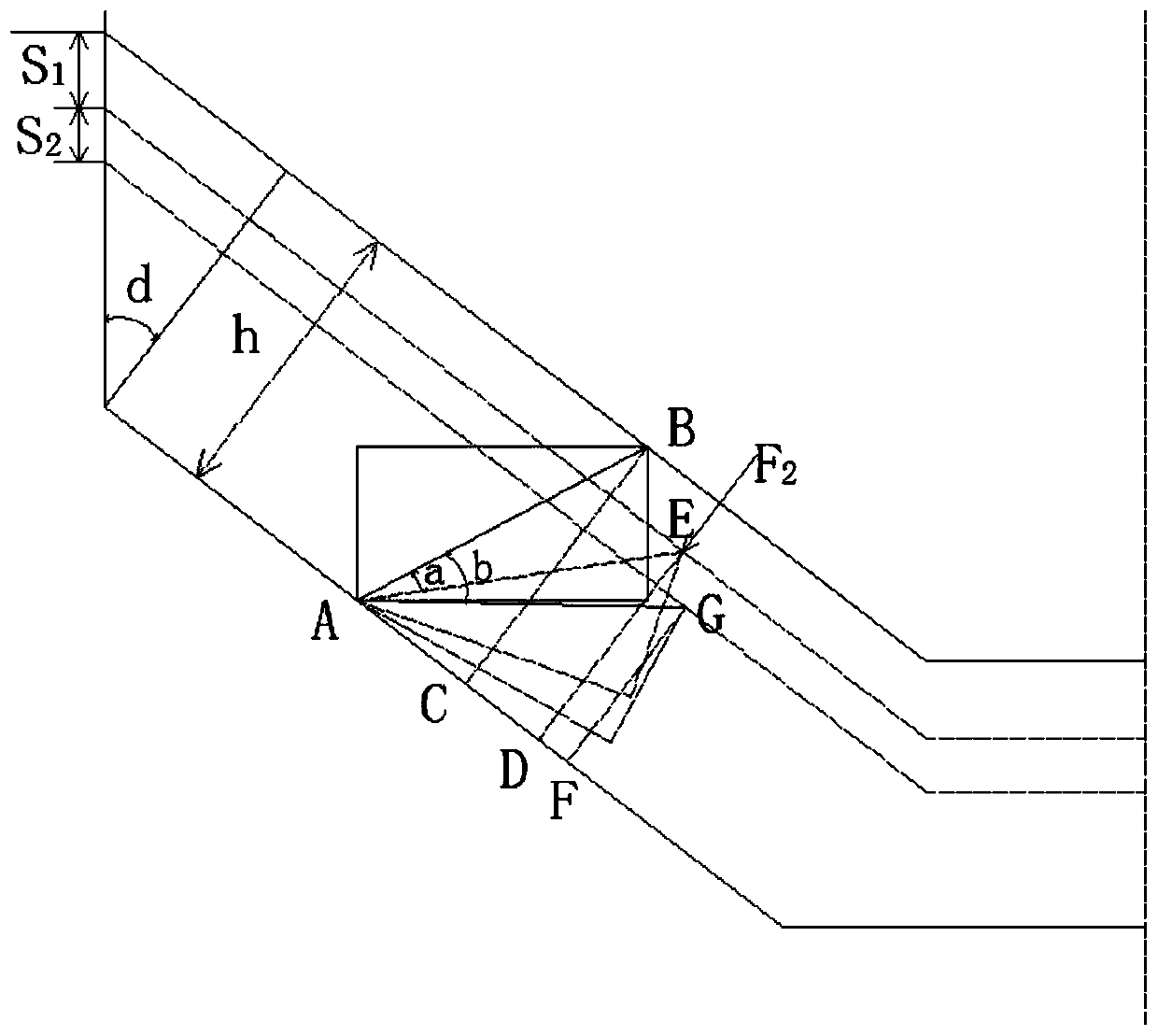

Return difference measuring device and method for harmonic gear transmission

InactiveCN111380681AImprove accuracyLow torque measurement accuracyMachine part testingHydraulic cylinderGear drive

The invention discloses a return difference measuring device and method for harmonic gear transmission. According to the invention, the input end of a wave generator of a harmonic reducer is connectedwith an input shaft fixing device through a key, the output end of a flexible gear of the harmonic reducer is fixedly connected with a loading rod, and an angle measuring device is connected to the loading rod to record the rotating angle of an output shaft of the harmonic reducer; and two force arm rod heads of the loading rod are sequentially provided with hydraulically-driven loading devices,and the loading devices are used for loading the output shaft. The return difference measuring device can adapt to the angle change of the loading rod by adopting a mode that a ball flange is tangentto the output plane of a hydraulic cylinder, and the loading rod head adopts a mode of vertically fixing a welding screw to ensure the accuracy of output torque measurement. The device is not only suitable for return difference measurement of harmonic gear transmission, but also suitable for return difference measurement of coaxial output gear transmission and is driven in a hydraulic mode, the rotation angle is measured by an angle encoder, and the torque is calculated by a force sensor. The device is simple in structure, convenient to install, high in measurement precision and high in practicability.

Owner:DALIAN UNIV OF TECH

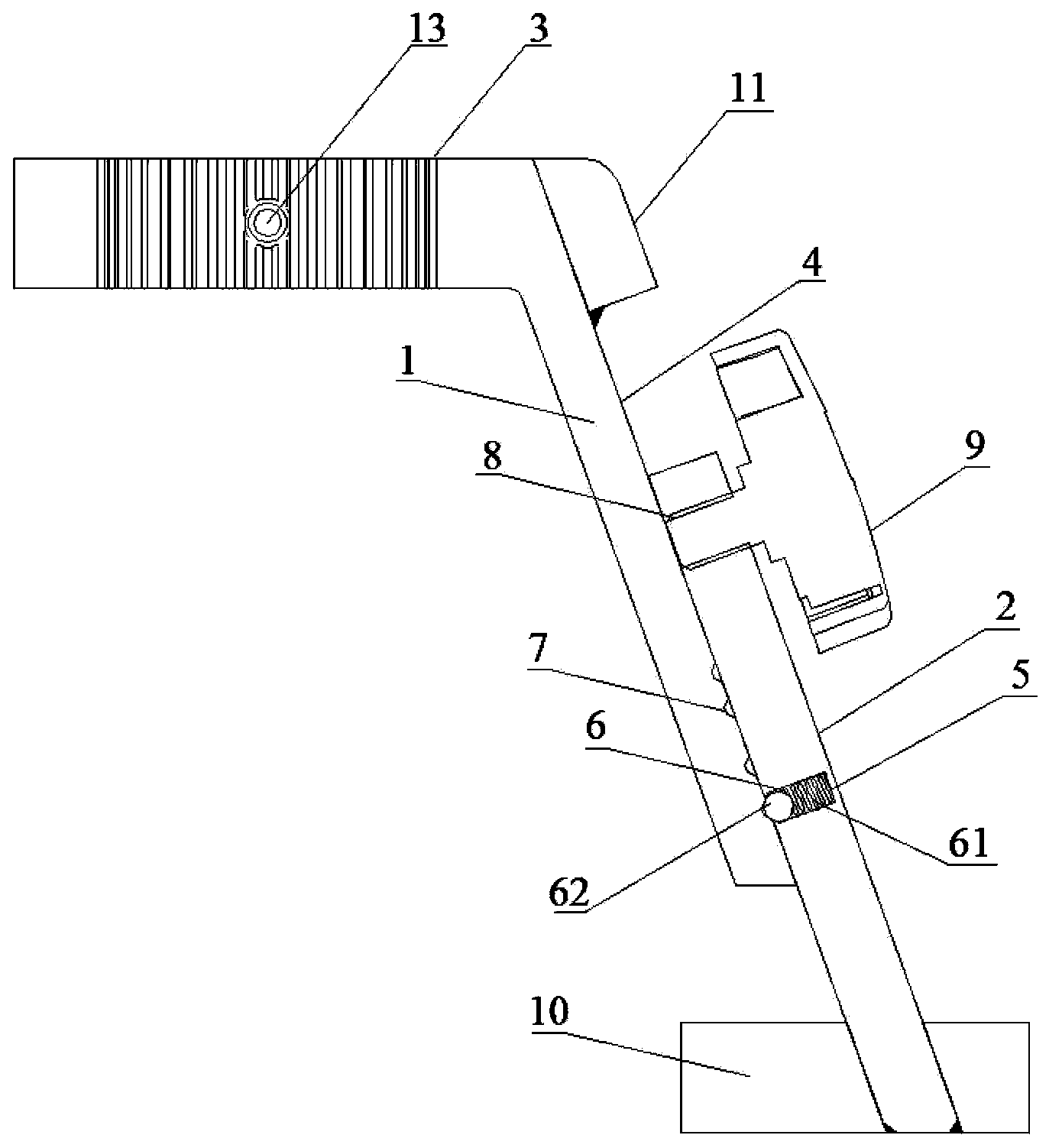

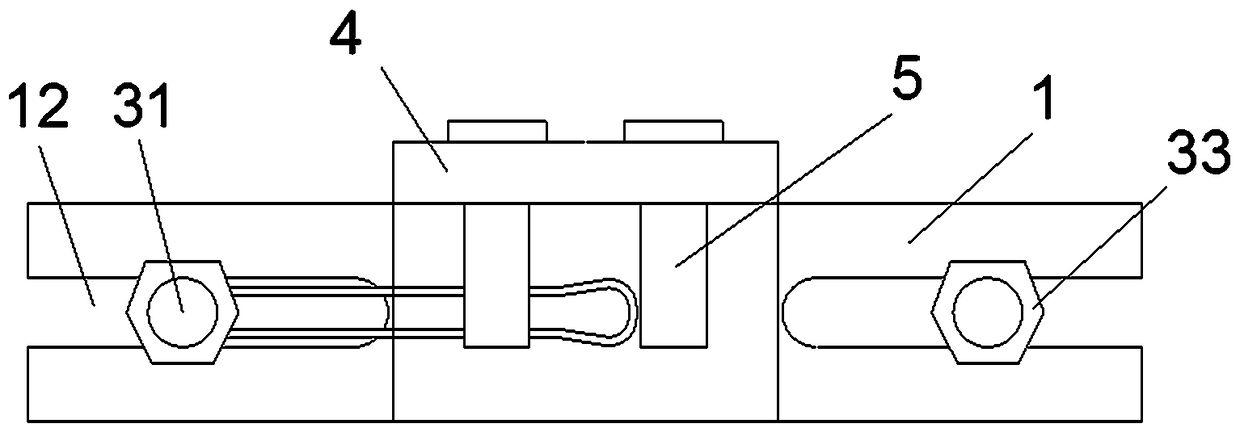

Reaction force arm for fixed torque wrench

InactiveCN103846853AImprove work efficiencyHigh strengthSpannersWrenchesEngineeringUltimate tensile strength

The invention discloses a reaction force arm for a fixed torque wrench and belongs to the field of equipment tools. The arm comprises an L-shaped main arm body, a location gear ring is arranged on a planar arm body of the main arm body, a dovetail groove is formed in an inclined arm body of the main arm body, and a location hole is formed in the bottom of the dovetail groove. The reaction force arm further comprises a dovetail moving arm body meshed with the dovetail groove, a location installation hole is formed in the middle of the moving arm body, an elastic location device is installed in the location installation hole, a threaded groove and a locking knob matched with the threaded groove are formed in one side of the upper end of the moving arm body, and a baffle is arranged on one side of the lower end of the moving arm body. The reaction force arm adopts the dovetail groove structure design, the length of the force arm is adjusted by stretching and retreating of the moving arm body to adapt to different work conditions, and the working efficiency is improved. The tooth shape is designed by adopting a 30-degree pressure angle, so that the gear strength is improved. The main arm body adopts the flexible arc anti-torque design, so that the torque accuracy is improved.

Owner:江苏金立电子机械科技有限公司

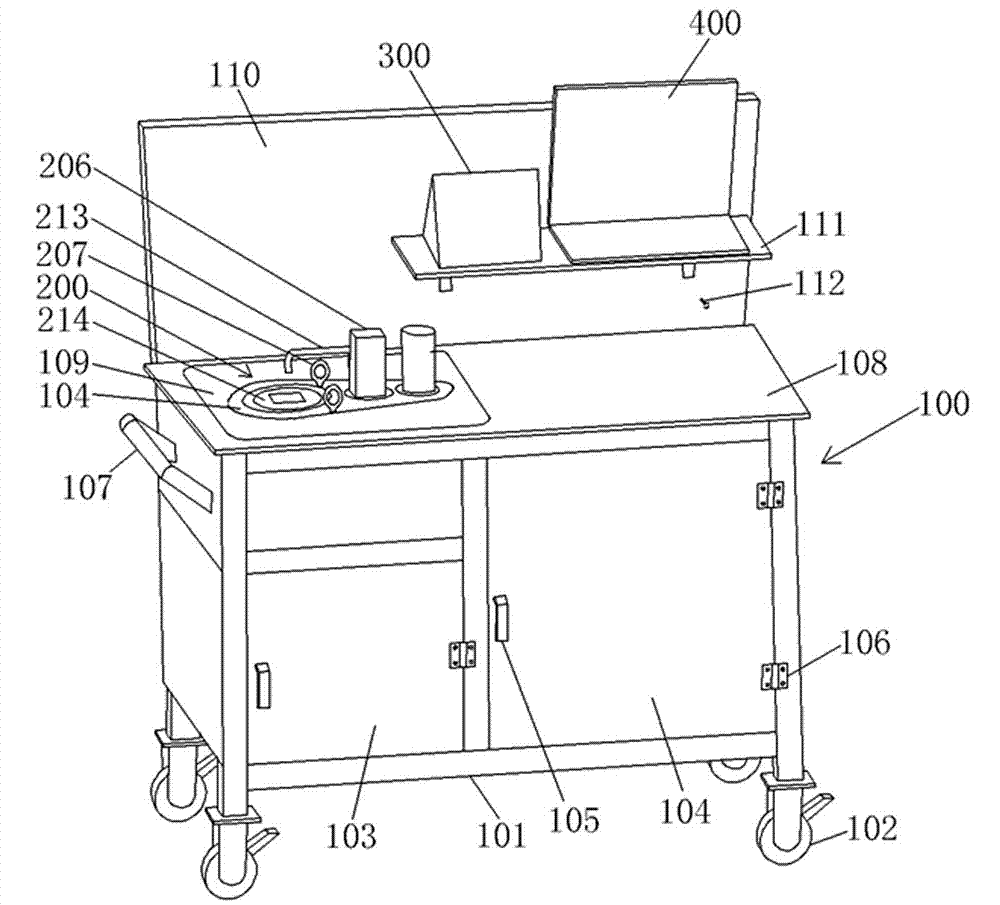

Detecting trolley of hydraulic torque wrench

InactiveCN104236783ATimely detection of torque accuracy problemsImproved Torque AccuracyMeasurement of torque/twisting force while tighteningEngineeringControl theory

The invention discloses a detecting trolley of a hydraulic torque wrench. The detecting trolley comprises a tool trolley and a torque detecting mechanism disposed on the tool trolley. The torque detecting mechanism comprises a base, a static torque sensor, a fixing plate, a needle bearing and counter-acting force columns. The base is connected with the tool trolley through base fixing bolts. The static torque sensor is disposed in the mounting groove of the base. The output shaft on the lower portion of the static torque sensor is mounted into the connecting square hole in the lower portion of the base. A fixing plate is connected to the upper end of the base through positioning pins. The fixing plate is provided with a mounting through hole right above the mounting groove. The needle bearing is disposed in the mounting through hole. The input shaft on the upper portion of the static torque sensor is mounted into the needle bearing. The fixing plate is provided with counter-acting force columns mounting holes beside the mounting through hole. A lining is disposed in each counter-acting force columns mounting hole. The lower portion of each counter-acting force column is connected into the corresponding lining. By the detecting trolley, torque precision detection of the hydraulic torque wrench can be completed in a production field.

Owner:NORBAR TORQUE TOOLS (SHANGHAI) LTD

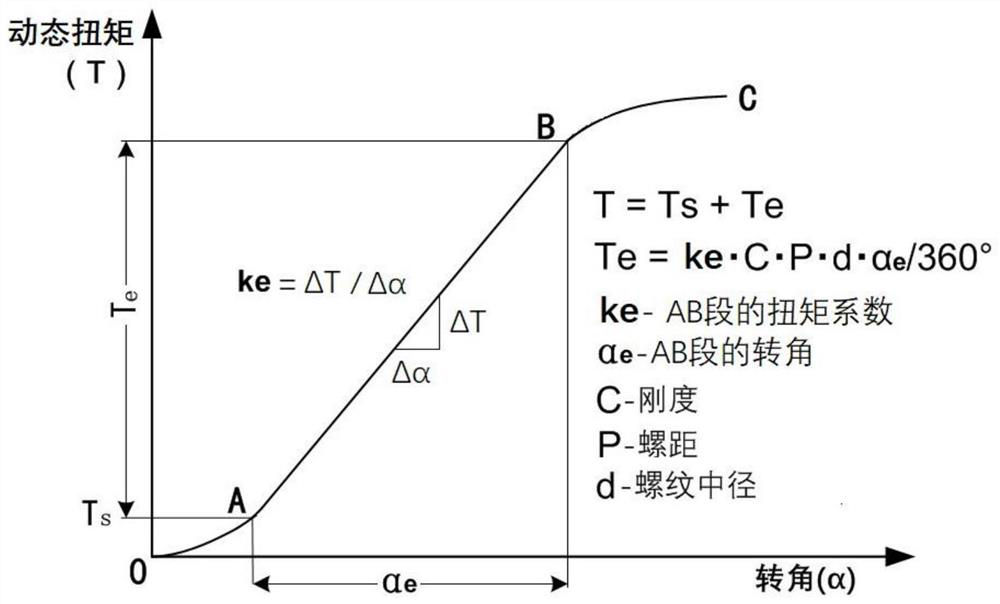

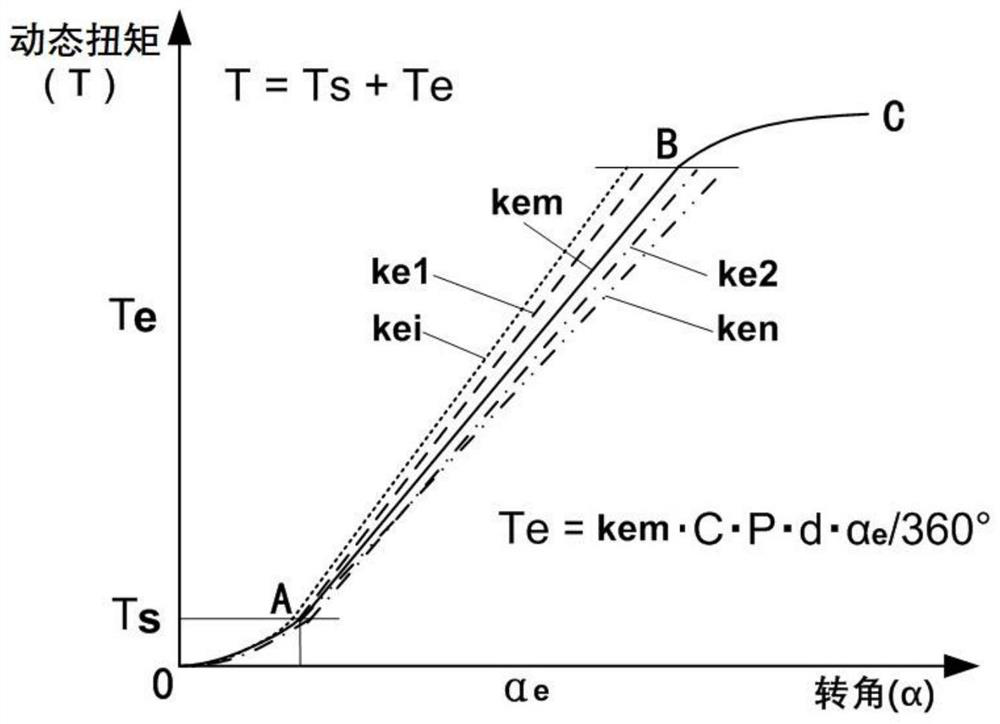

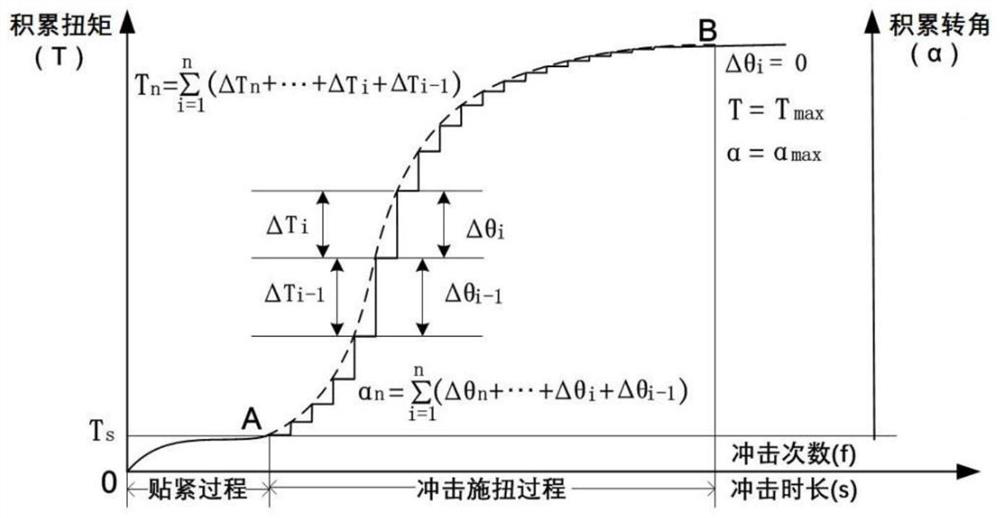

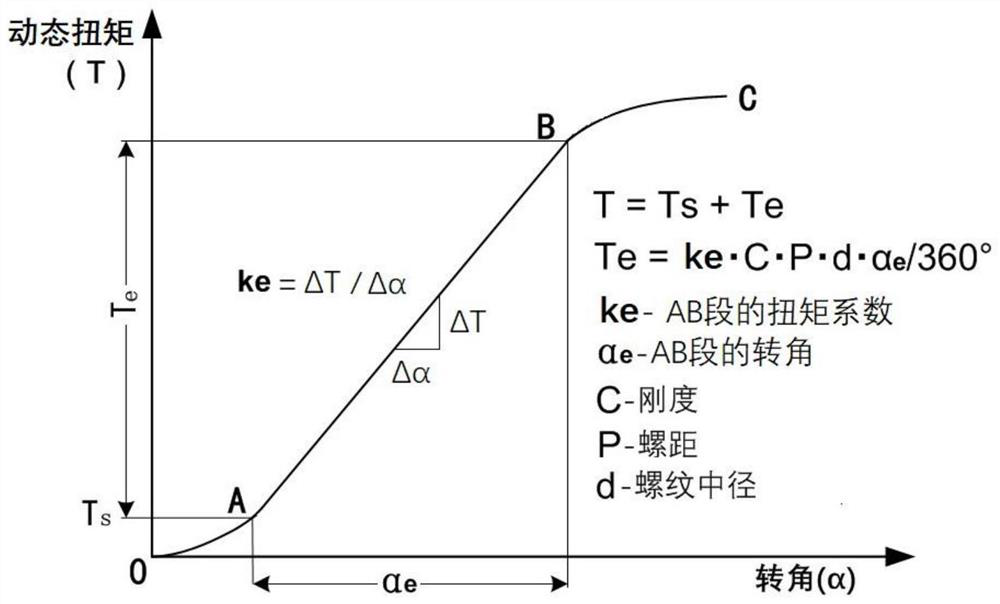

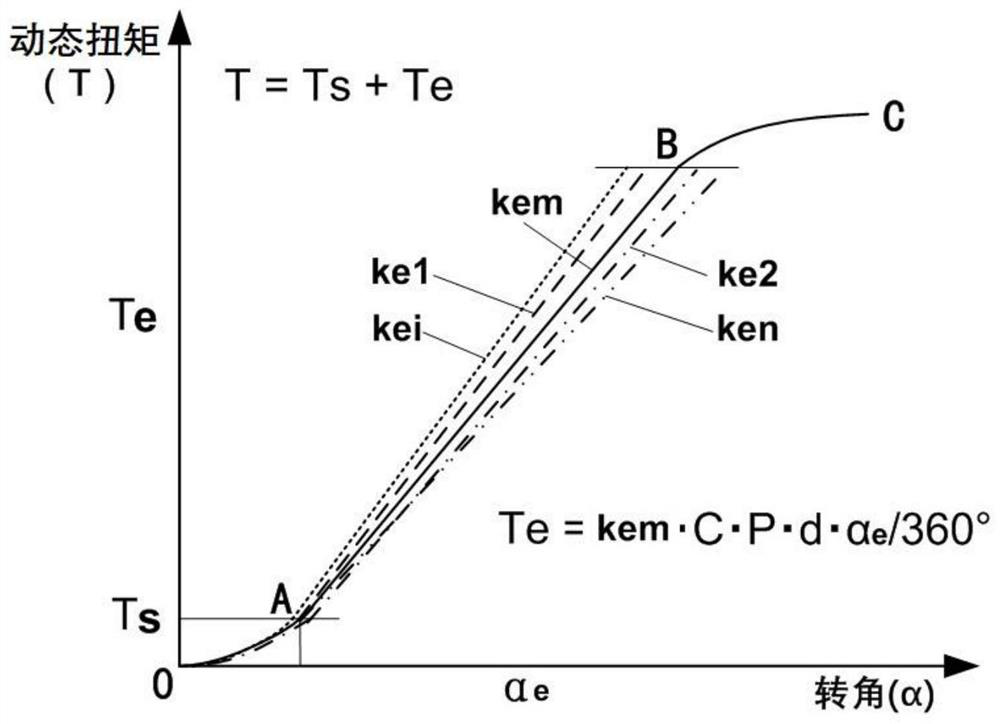

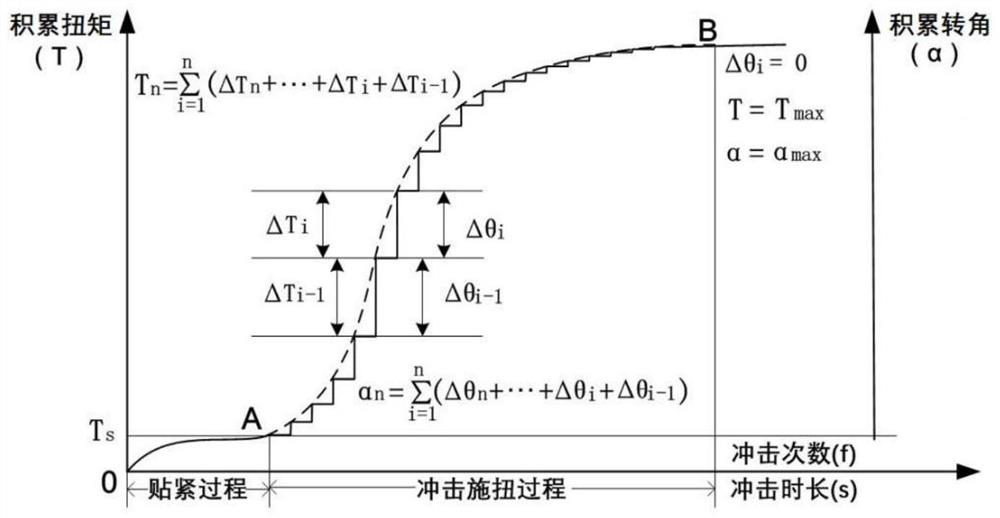

Torque on-line measurement method and device for torque-controllable impact wrench

ActiveCN113390543ASolve measurement problemsImprove the quality of twisting operationMeasurement of torque/twisting force while tighteningWork measurementWorking environmentEngineering

The invention relates to a torque on-line measurement method and device for a torque-controllable impact wrench. According to the method, aiming at the working environment of a twisting operation site and the elastic stage of bolt working, multiple sets of thread pairs to be twisted and workpieces in the same batch are twisted by the same process, and an accurate dynamic torque and rotation angle relational expression is measured, established and stored; and in the measuring process, an on-line measuring device detects the accumulated rotating angle of the bolt / nut in the impact torque application process in real time, the accumulated rotating angle is substituted into the dynamic torque and rotation angle relational expression, and the accumulated torque of the impact torque application of the controllable torque impact wrench is calculated and displayed. According to the invention, on-line measurement of the accumulated torque of the impact wrench is innovatively realized, the torque control accuracy is ensured, and the application range of the impact wrench is expanded.

Owner:中国铁路郑州局集团有限公司科学技术研究所 +1

Fluid-operated torque wrench for and method of tightening or loosening fasteners

InactiveUS20090107305A1Reduce frictionImproved Torque AccuracySpannersWrenchesEngineeringStationary object

A fluid-operated torque wrench for tightening or loosening a fastener has a housing having two housing portions including a cylinder portion and a driving portion, cylinder-piston means arranged in the cylinder portion and movable along a first axis, a lever-type ratchet mechanism arranged in the driving portion and connected to the cylinder-piston means to be driven by the later, the lever-type ratchet mechanism having a ratchet turnable about a second axis which is perpendicular to the first axis, at least three connecting elements including first and second connecting elements receiving a given turning force acting in one direction during operation of the wrench, and a third connecting element receiving a turning force in an opposite direction during operation of the wrench and being equal to the given turning force acting in the one direction, so that one of the turning forces turns a fastener to be tightened or loosened while another of the turning forces is transferred to a stationary object.

Owner:HYTORC DIV UNEX CORP

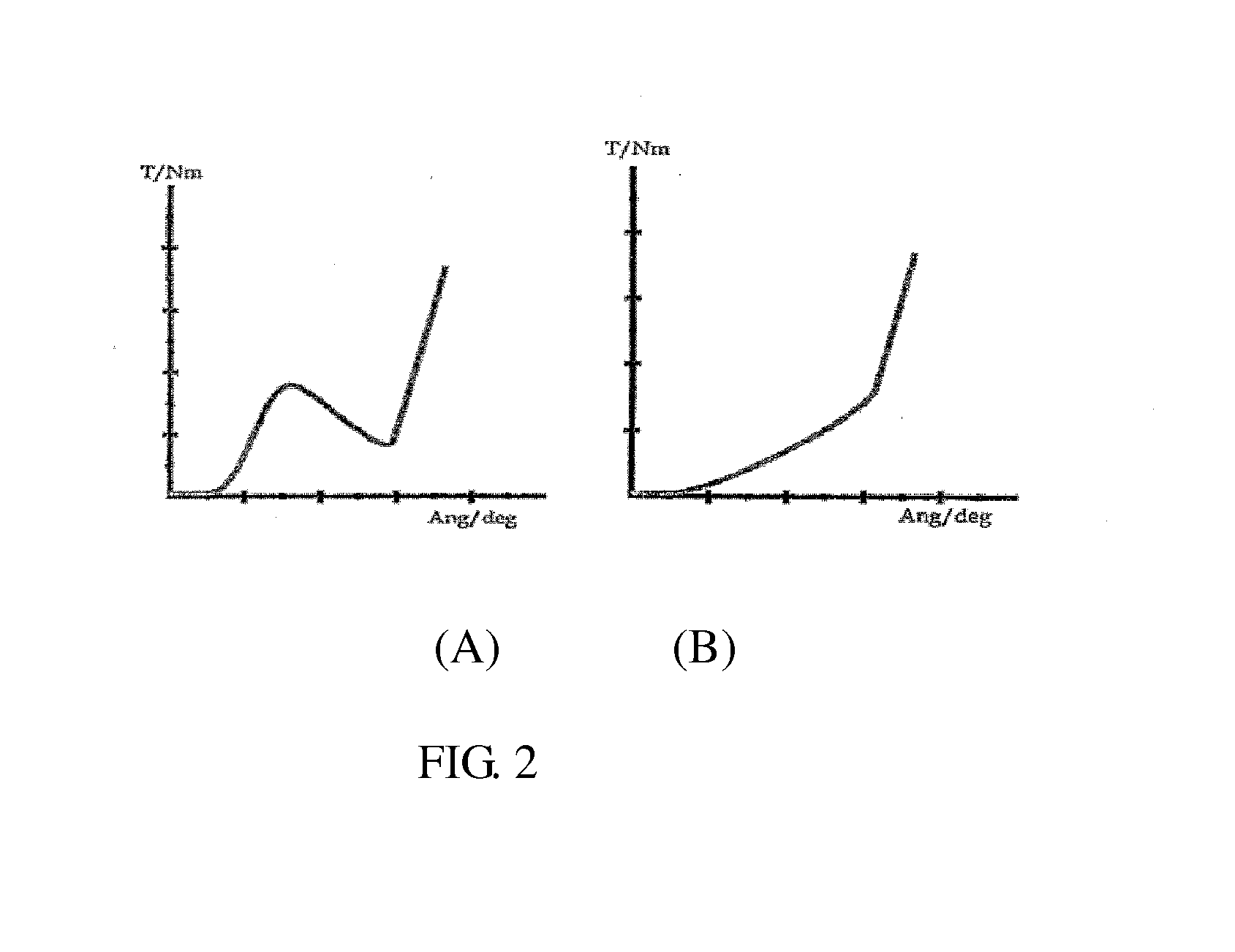

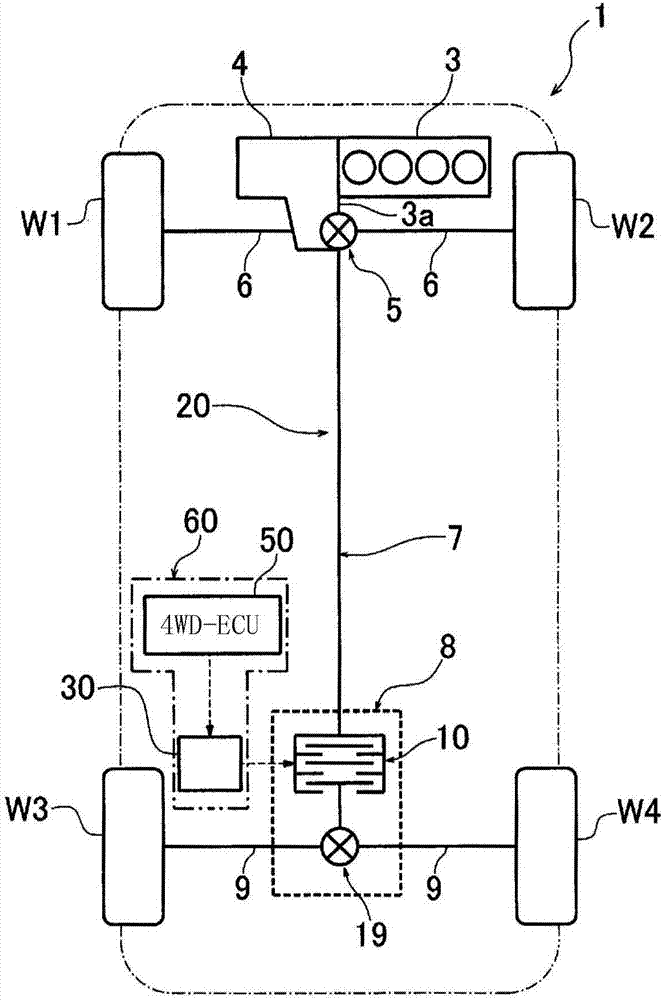

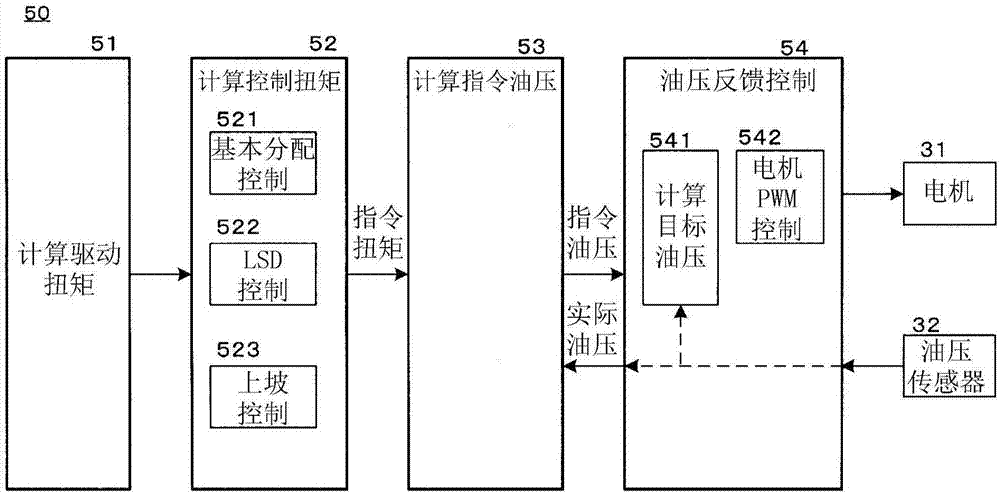

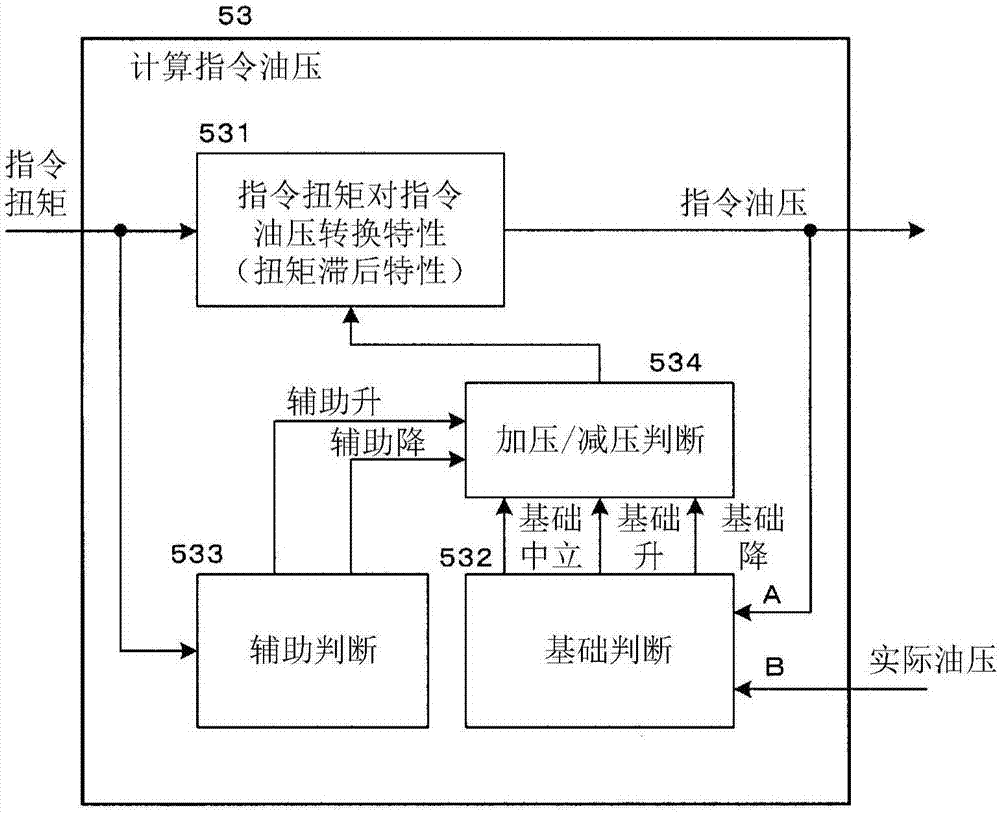

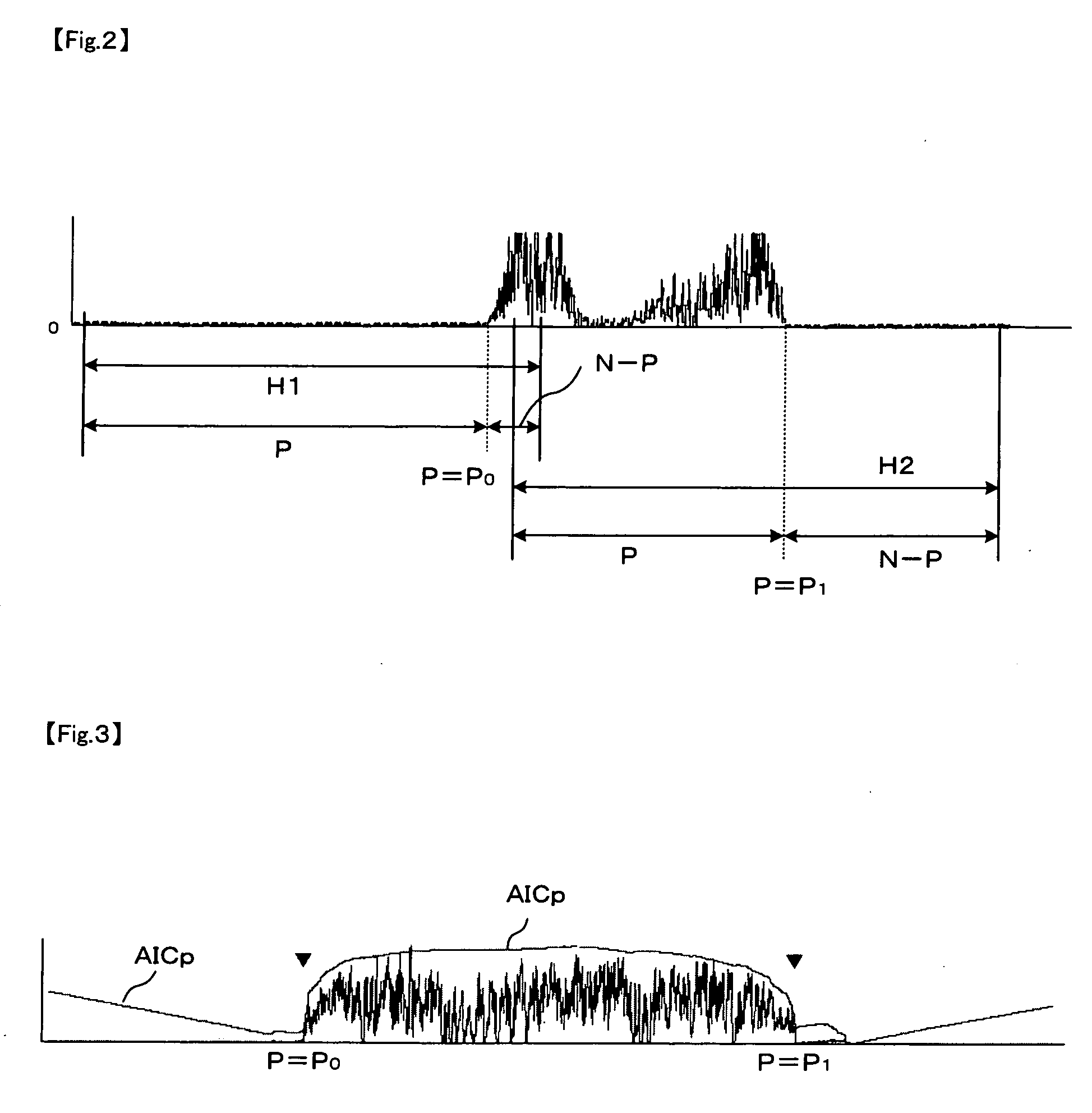

Device and method for controlling oil pressure of vehicle

An assessment of 'base neutral ' is made when the difference between a command oil pressure and the actual oil pressure of a hydraulic clutch is within a prescribed microvalue range, and when the difference is outside of the microvalue range, an assessment of 'raise base' is made if the command oil pressure is greater than the actual oil pressure, and an assessment of 'lower base' is made if the command oil pressure is less than the actual oil pressure. An assessment of 'raise sub' is made when the command torque processed using a low-pass filter tends to be positive for at least a prescribed time, an assessment of 'lower sub' is made when the command torque tends to be negative for at least a prescribed time, and the tendency of the command torque to increase or decrease is assessed. When the assessment is 'raise base', the command oil pressure corresponding to the command torque is determined using a pressurization characteristic in hysteresis characteristics, and when the assessment is 'lower base ', the command oil pressure is determined using a depressurization characteristic. When the assessment is 'base neutral', the command oil pressure is determined using the pressurization characteristic when the assessment of 'raise sub' has been made, and the depressurization characteristic is used when the assessment of 'lower sub' has been made.

Owner:HONDA MOTOR CO LTD

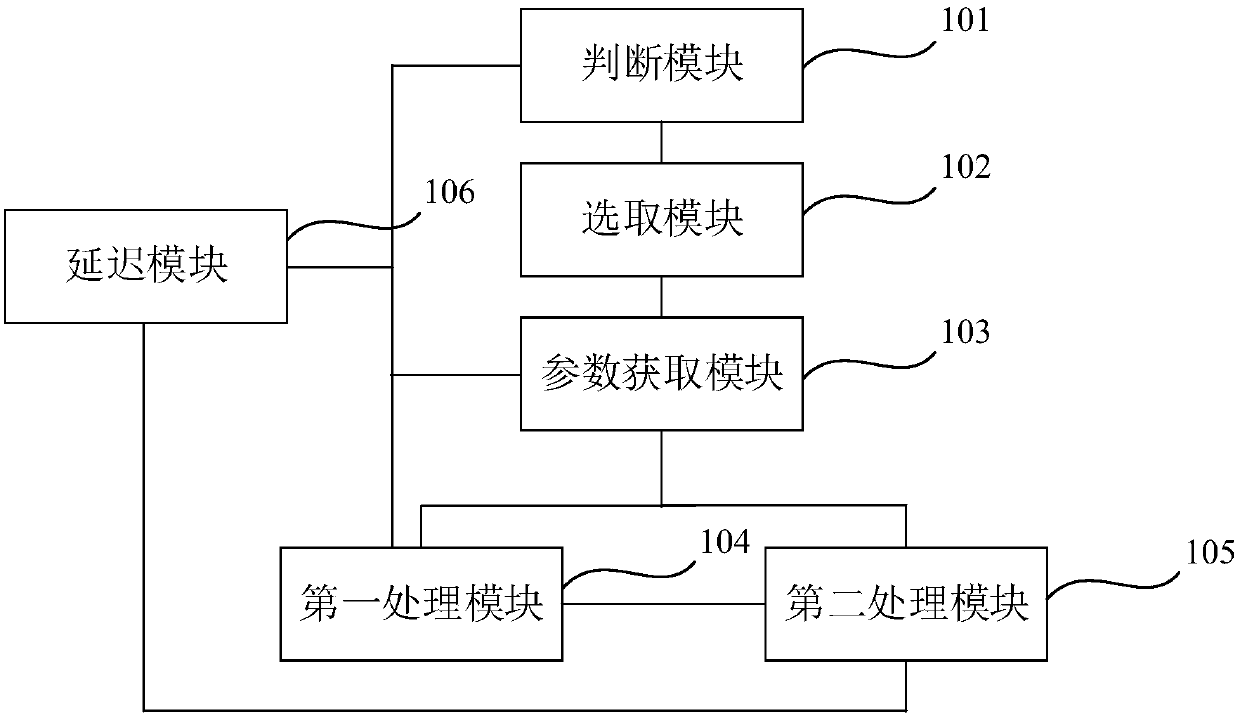

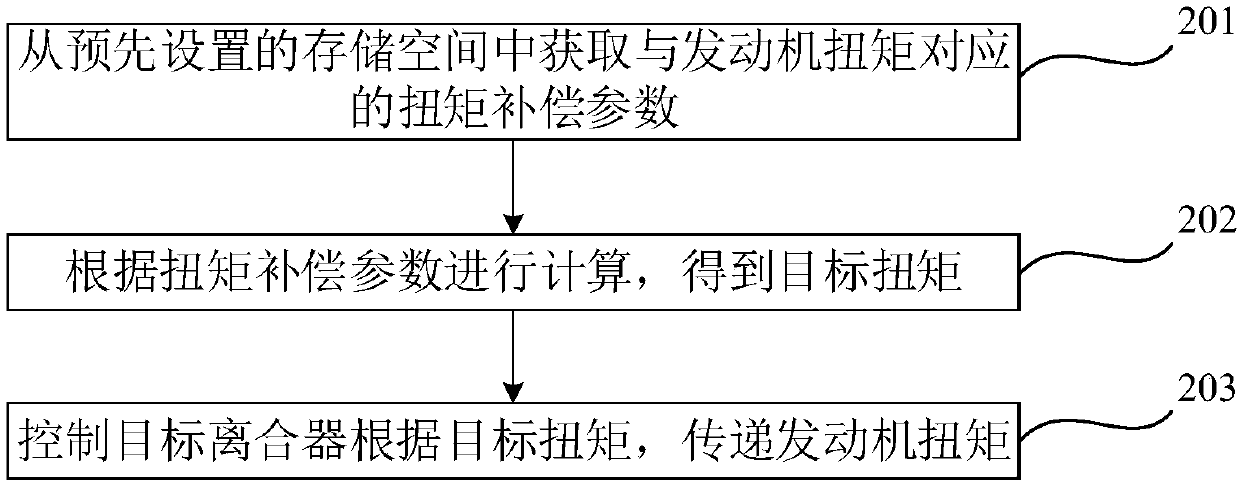

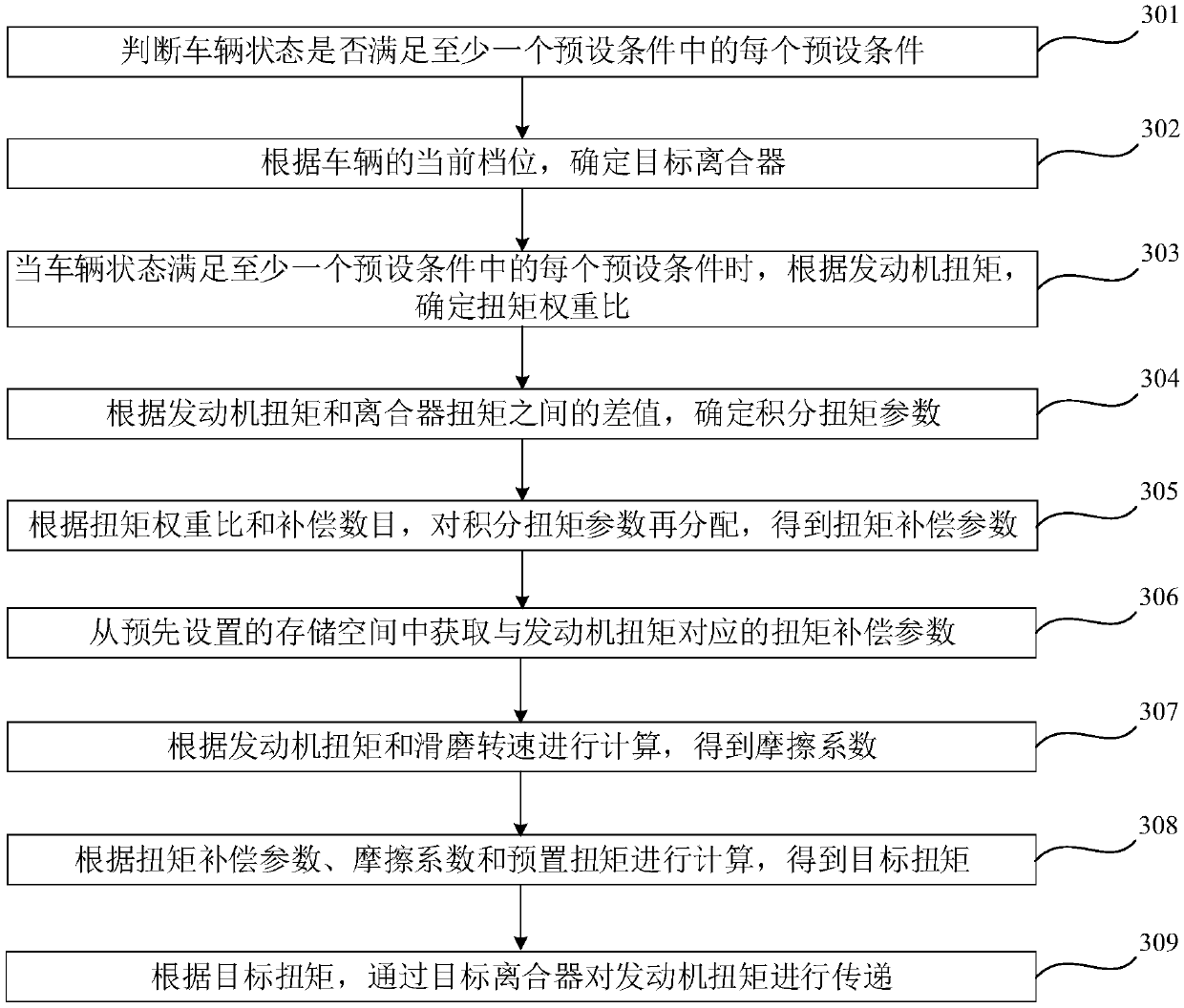

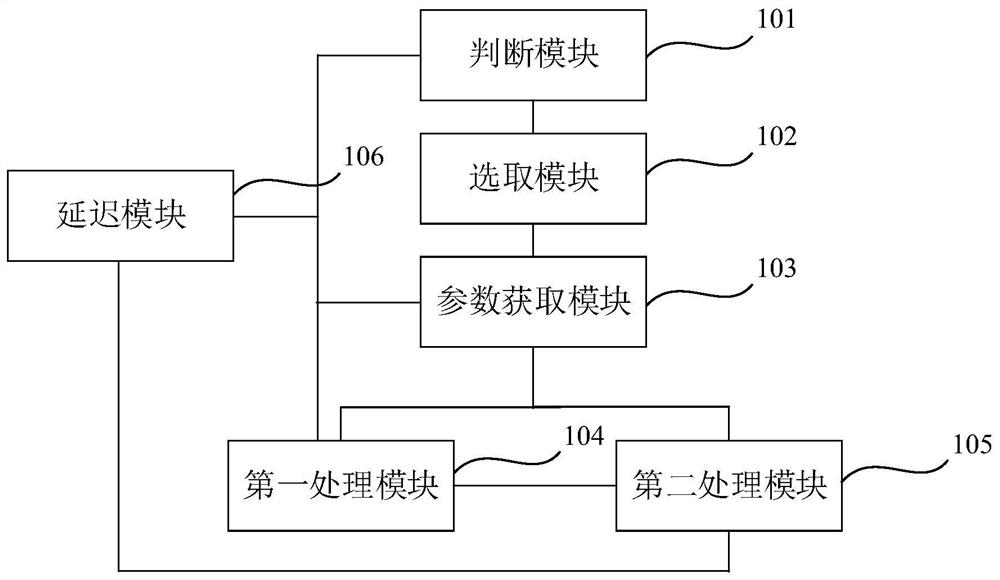

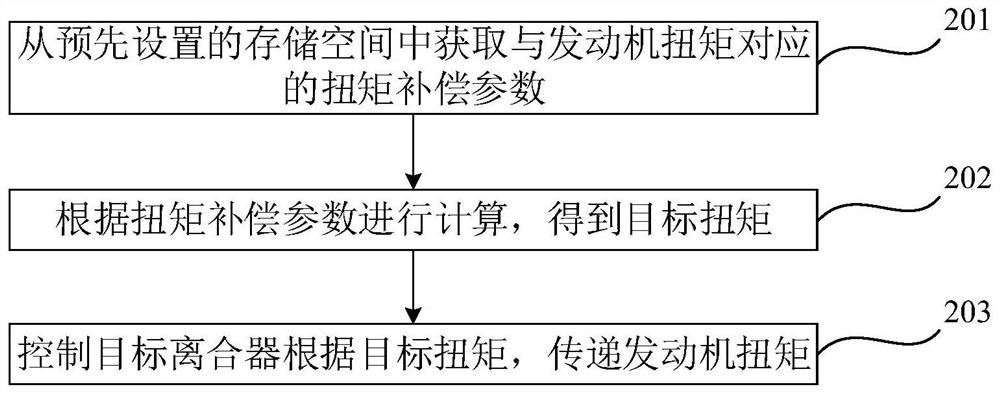

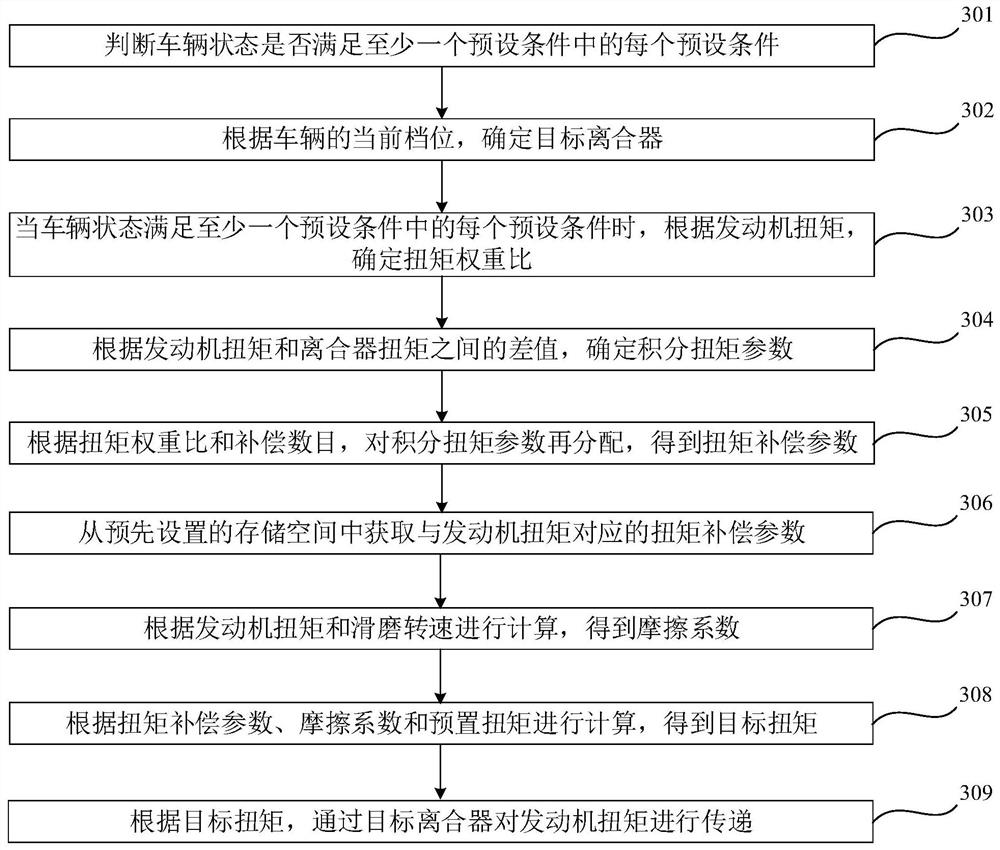

Torque transmission method and device

ActiveCN110094495AImprove securityImprove Torque AccuracyGearing controlTorque transmissionControl theory

The invention provides a torque transmission method and device. The torque transmission method includes the following steps: obtaining a torque compensation parameter corresponding to engine torque from a preset storage space, calculating according to the torque compensation parameter to obtain target torque, according to the target torque, controlling a target clutch, and transmitting the enginetorque. According to the torque transmission method, the torque compensation parameter corresponding to the torque of the engine is obtained from the preset storage space, calculation is performed according to the torque compensation parameter to obtain the target torque, and finally, according to the target torque, the target clutch is controlled, and the torque of the engine is transmitted, a control strategy of a dry double clutch transmission is avoided to apply to a wet double clutch transmission, the degree of accuracy of transmission of the engine torque of the wet double clutch transmission is improved, and the safety of driving of a vehicle is improved.

Owner:GREAT WALL MOTOR CO LTD

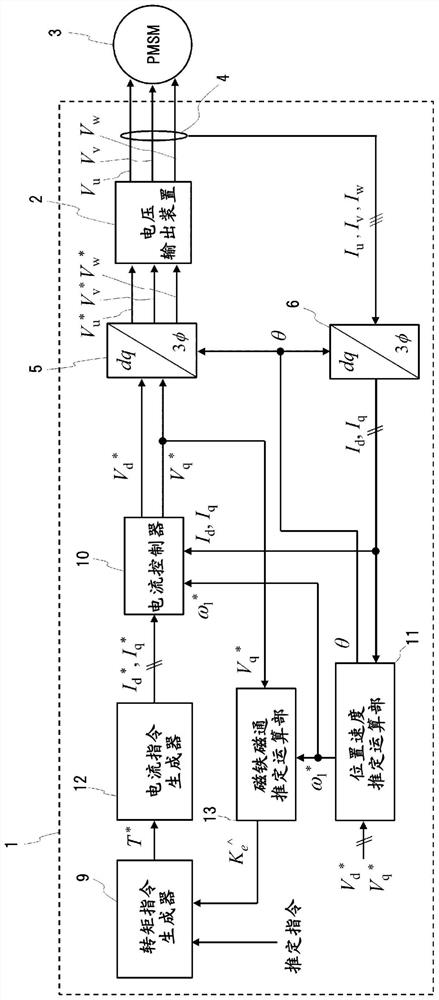

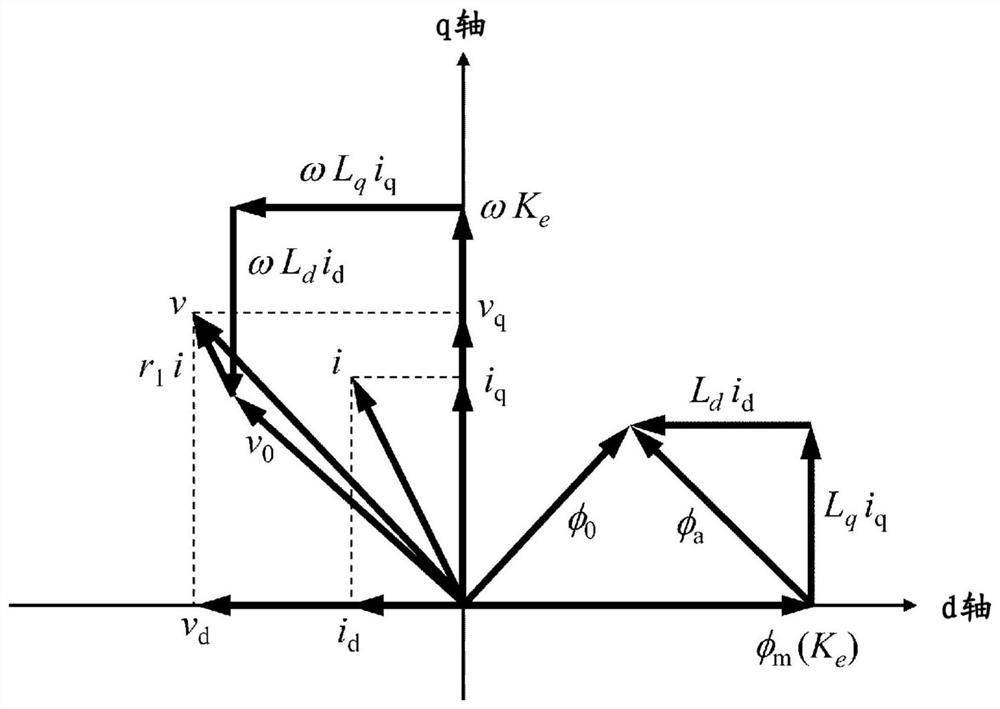

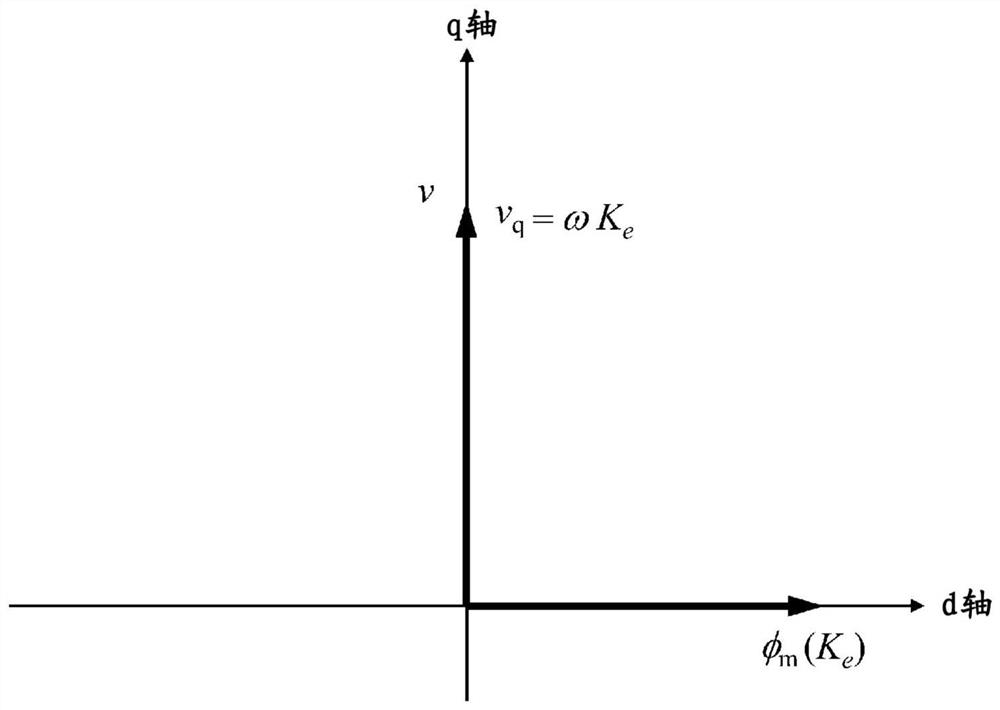

Driving device, driving system, and driving method for permanent magnet synchronous motor

PendingCN112292809ARobust and Highly Accurate EstimationImproved Torque AccuracyElectronic commutation motor controlElectric motor controlSynchronous motorPermanent magnet synchronous motor

When controlling the driving of a permanent magnet synchronous motor, in order to estimate magnet's magnetic flux with high accuracy and robustness against harmonic components of induced voltage and errors in setting constants for resistance and inductance without using a voltage sensor, a speed sensor, and data from magnetic field analysis or experiments, this driving device for a permanent magnet synchronous motor has capability of improving torque accuracy by estimating the amount of magnetic flux or the temperature of the magnet in the permanent magnet synchronous motor on the basis of a voltage command value and speed information about the permanent magnet synchronous motor, in a state in which a current command value when the torque command value is zero is being output, so as to estimate the magnet's magnetic flux or the temperature with high accuracy and robustness against harmonic components of induced voltage and errors in setting constants for resistance and an inductance without using the data from magnetic field analysis or experiments.

Owner:HITACHI LTD

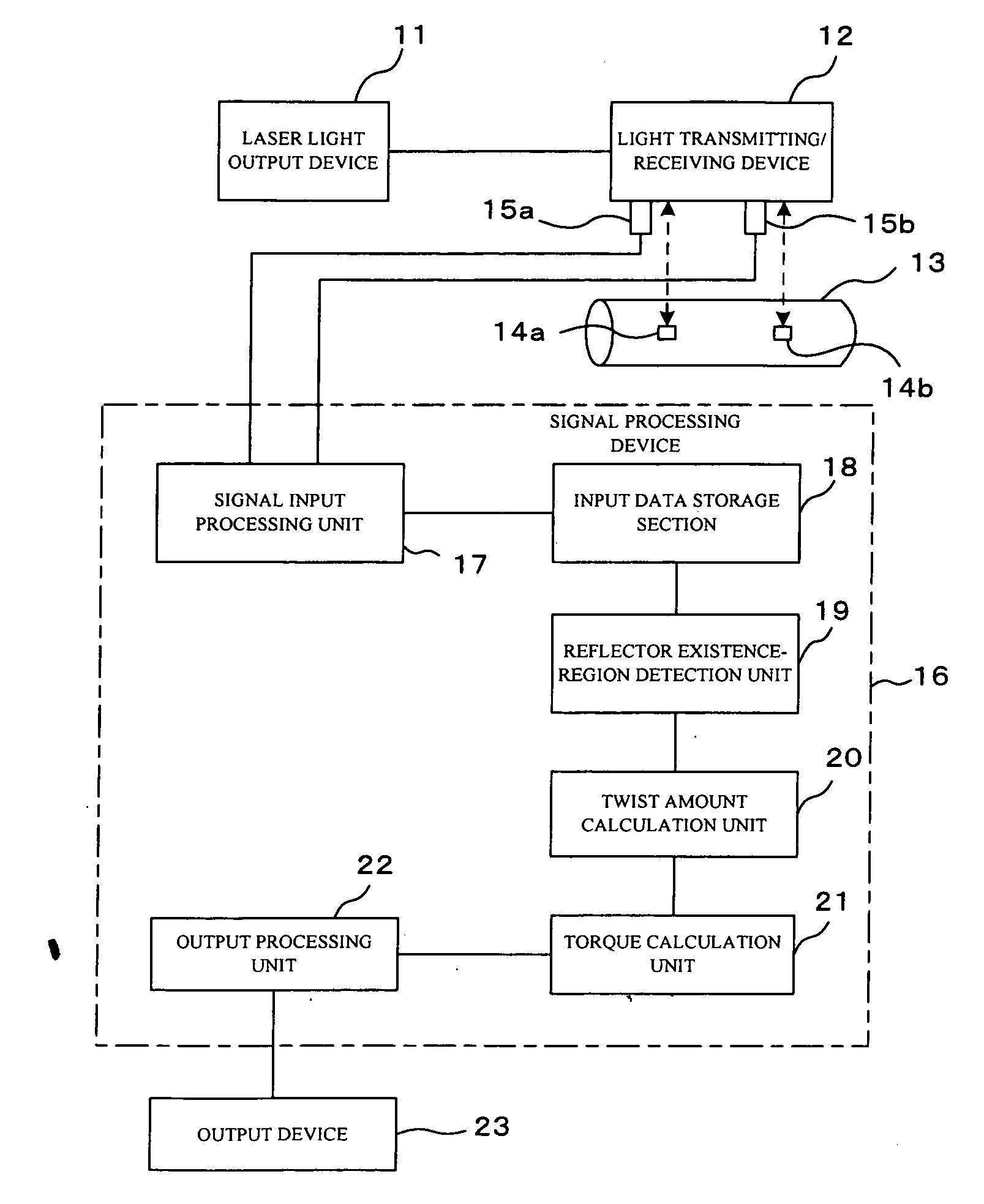

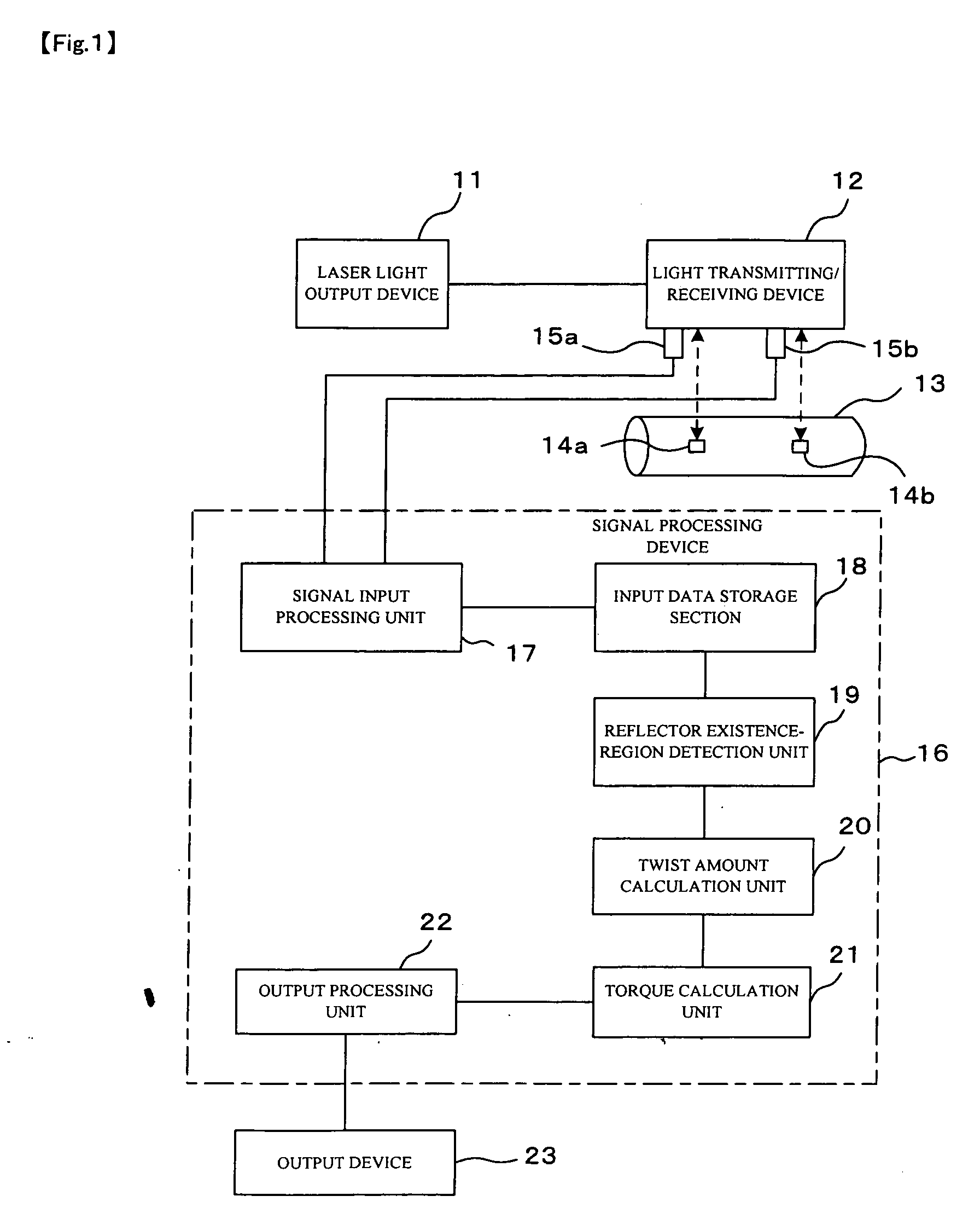

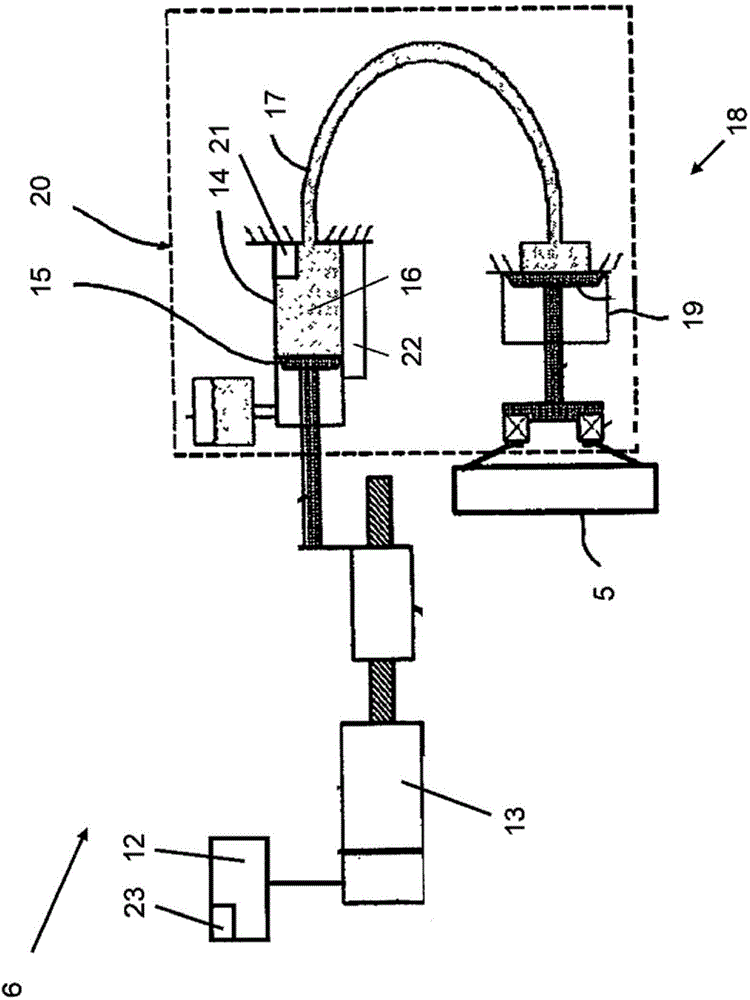

Torque measurement device and program

InactiveUS20090326838A1Easy to detectImproved Torque AccuracyForce measurementWork measurementMeasurement device

[Problems] To provide a torque measurement device capable of more accurately specifying positions of reflectors which are attached to a rotating body, and more accurately obtaining a torque of the rotating body.[Means for Solving Problems] A pair of reflectors (14a, 14b) is provided on the surface of the rotating body (13) and has a spacing in the axial direction, reflected light data obtained by reflection of reflection patterns in the pair of reflectors (14a, 14b) is input and stored, a point of minimizing AIC is determined for a model of the reflected light data from the rotating body (13), and existence regions of the pair of reflectors (14a, 14b) are detected. Then, a twist amount of the rotating body (13) is calculated from the reflector positions specified by the detected existence regions of the pair of reflectors (14a, 14b), and the torque is calculated from the calculated twist amount of the rotating body.

Owner:THE TOKYO ELECTRIC POWER CO INC

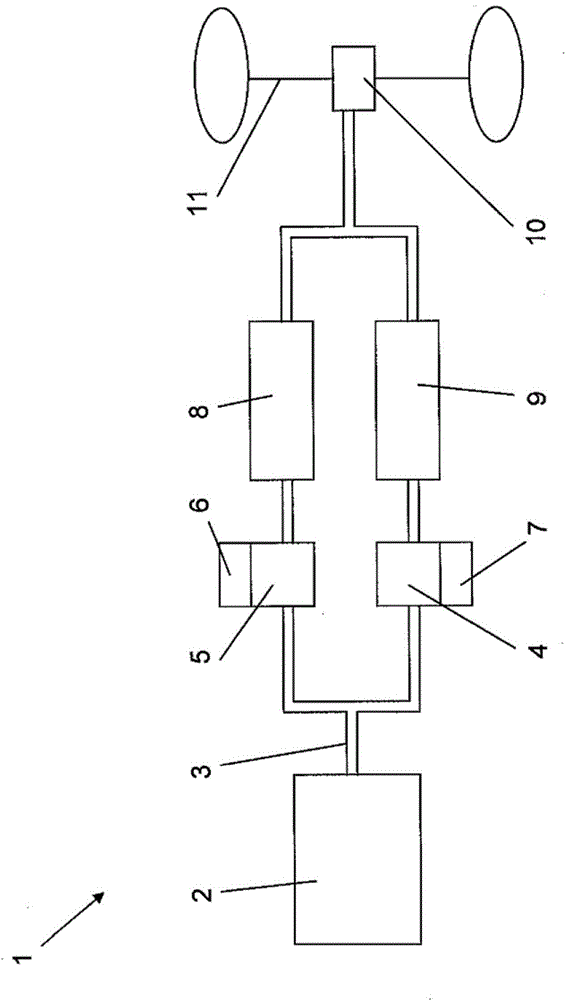

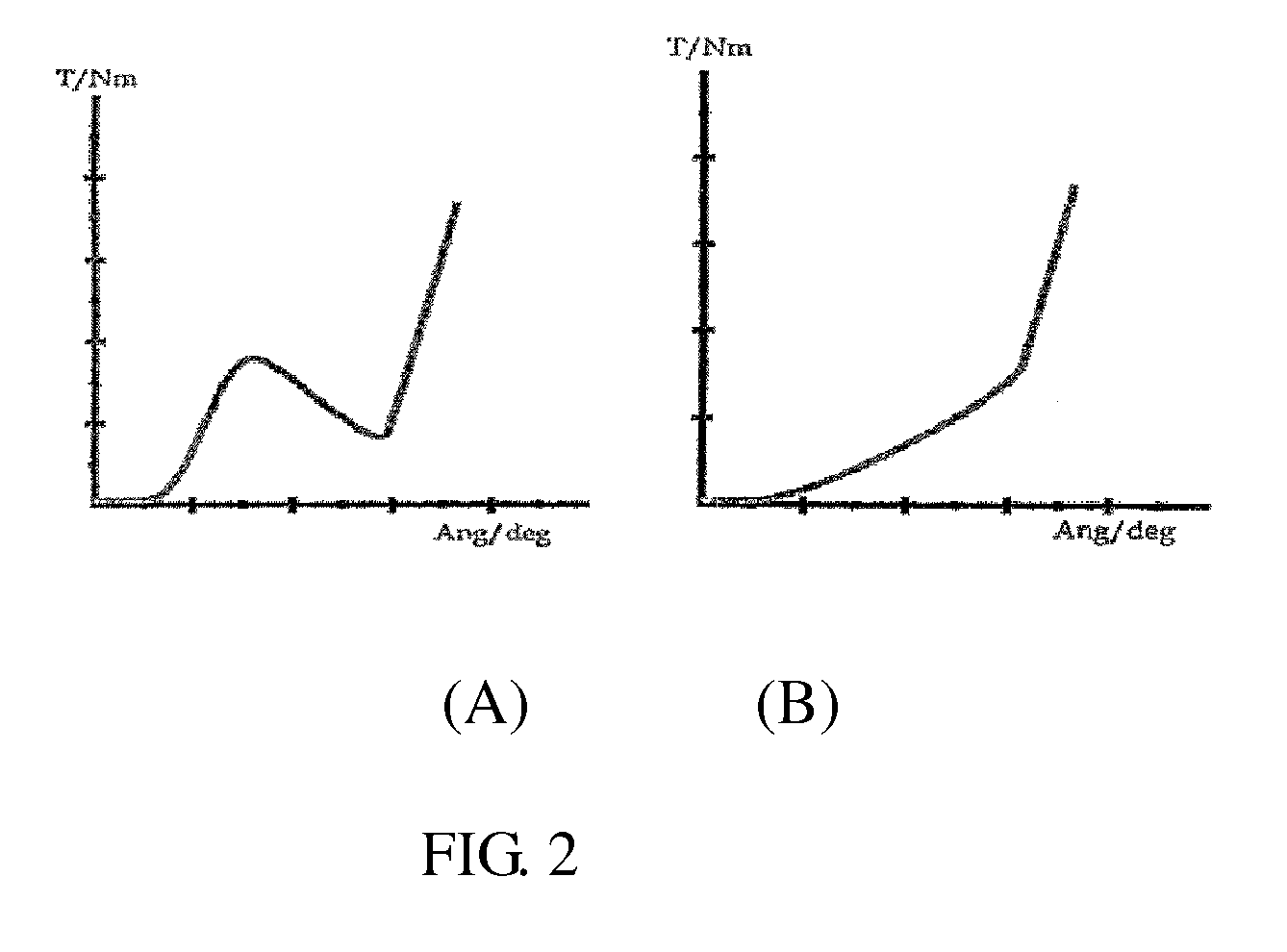

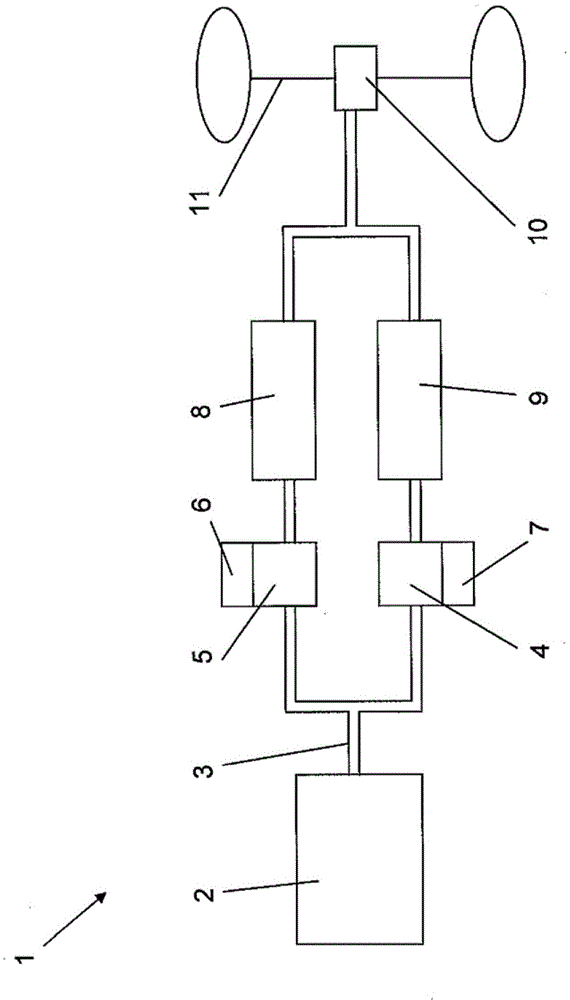

Method for determining and/or offsetting crosstalk behaviour of a dual clutch transmission

The invention relates to a method for determining the crosstalk behaviour of a hydrostatic dual clutch transmission of a motor vehicle which has two partial transmission clutches (4, 5) that are each arranged between a drive unit (2) and a partial transmission (8, 9), wherein the two partial transmission clutches (4, 5) are each actuated independently of one another via a partial transmission clutch actuator (6, 7), wherein during the actuation, the actuation pressure (p4, p5) from the partial transmission clutch actuator (6, 7) acting on the partial transmission clutch (4, 5) and a clutch actuation path travelled by the partial transmission clutch (4, 5) are determined, from which a crosstalk factor (Deltax4, Deltax5) is determined for each partial transmission clutch (4, 5). In a method for determining the crosstalk behaviour of a hydrostatic dual clutch transmission, wherein said behaviour can be determined both at the belt end and during the driving operation in the motor vehicle, each crosstalk factor (Deltax4, Deltax5) is derived from a characteristic map (K4, K5) which is generated depending on the actuation pressure (p4, p5) of both partial transmission clutches (4, 5).

Owner:SCHAEFFLER TECH AG & CO KG

Two-stage locking electric screwdriver

A two-stage locking electric screwdriver, with its main improved features as follow: the electric screwdriver has pre-locking and locking functions; the torque settings of the electric screwdriver can be easily modulated, and meanwhile the torque accuracy and energy efficiency can be improved; the torque modulation type is external modulation, so that the torque modulation can be carried out externally and even the torsion spring can be replaced. Meanwhile, the component structures inside the electric screwdriver is improved through a design that the motor directly drives the clutch and then drive the screwdriver head unit, and that an internal gear clutch is used to replaced the gear unit and clutch unit, so that the number of parts is dramatically reduced to save production cost. During general rotation, the electric screwdriver will not drive the clutch unit, and when the torque jumps to the set value, the internal gear clutch rotates and generates a torque.

Owner:HSU HSIU LIN

Method for determining and/or compensating crosstalk characteristics of a dual clutch transmission

Owner:SCHAEFFLER TECH AG & CO KG

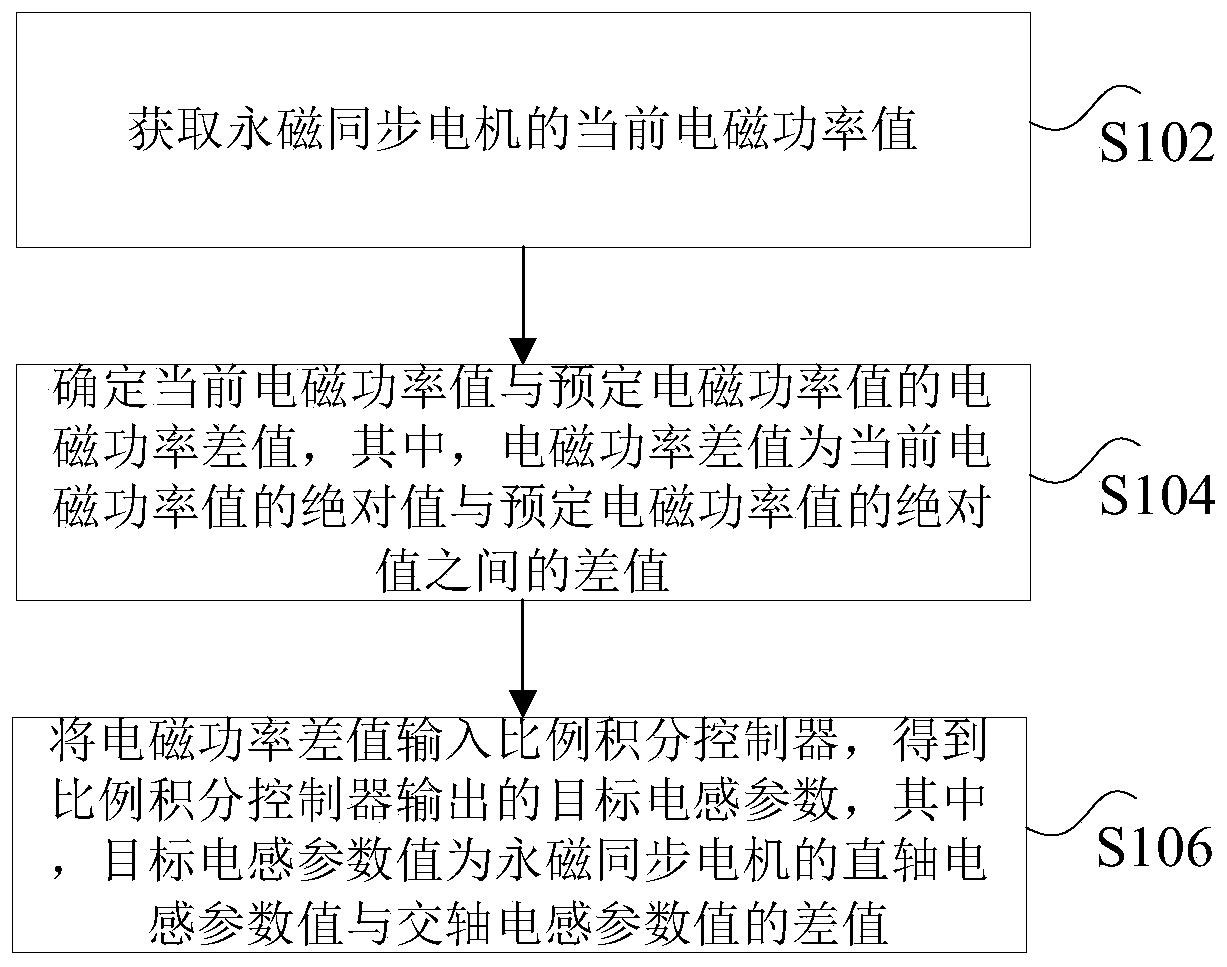

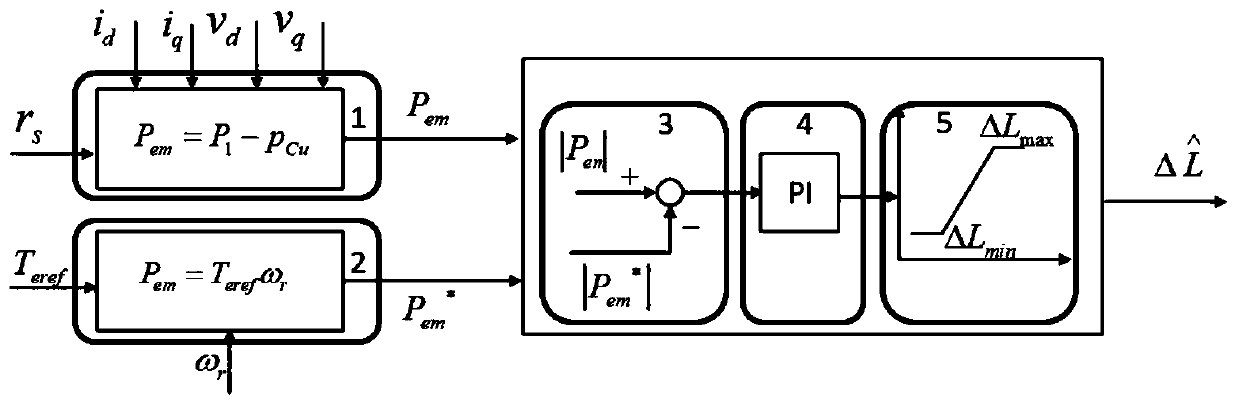

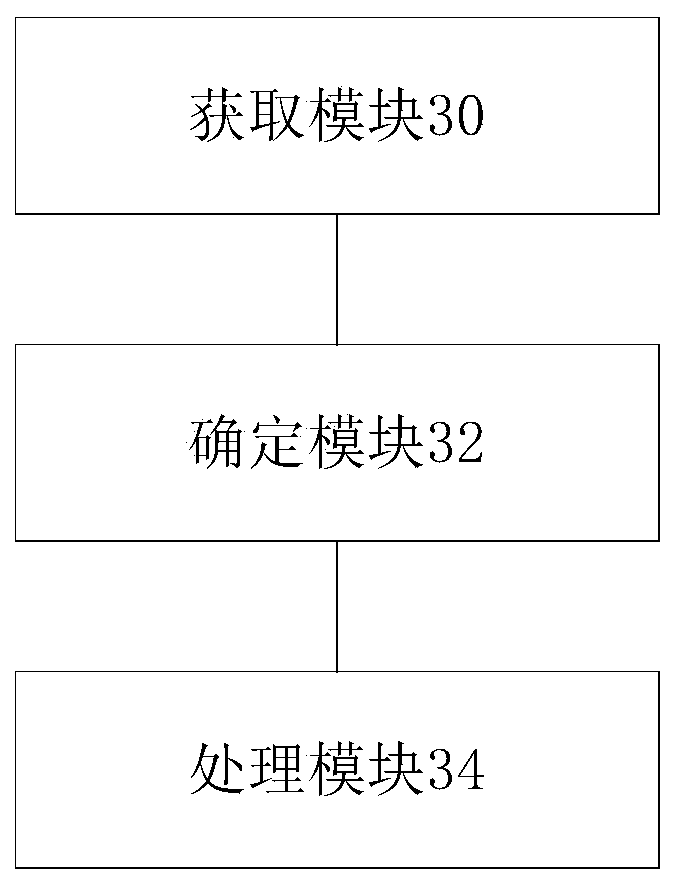

Inductance parameter obtaining method and device

InactiveCN111277194AReduce mistakesImprove torque accuracyAC motor controlVector control systemsPhysicsEngineering

The invention discloses an inductance parameter obtaining method and device. The method comprises the following steps: acquiring a current electromagnetic power value of the permanent magnet synchronous motor; determining an electromagnetic power difference value between the current electromagnetic power value and a predetermined electromagnetic power value, wherein the electromagnetic power difference value is a difference value between an absolute value of the current electromagnetic power value and an absolute value of the predetermined electromagnetic power value; inputting the electromagnetic power difference value into a proportional-integral controller to obtain a target inductance parameter output by the proportional-integral controller, wherein the target inductance parameter value is the difference value between the direct-axis inductance parameter value and the quadrature-axis inductance parameter value of the permanent magnet synchronous motor. According to the method, thetechnical problem that the torque precision of the permanent magnet synchronous motor is reduced due to the fact that an existing permanent magnet synchronous motor inductance parameter identificationmethod is large in error is solved.

Owner:BEIJING JINGHUAN EQUIP DESIGN RES INST CO LTD +1

Stamping tool for semi-arc parts on torsional arms of middle and two ends of reset torsional spring

The invention discloses a stamping tool for semi-arc parts on torsional arms of the middle and two ends of a reset torsional spring. The stamping tool for the semi-arc parts on the torsional arms of the middle and two ends of the reset torsional spring comprises a concave die and a convex die, the concave die is provided with a protrusion part, and the protrusion part is fixedly connected with theconcave die, located in the center of the end face of the concave die, and provided with a groove; the groove is located in the side away from the concave die, the convex die is located above the concave die and provided a protrusion, the protrusion and the convex die are integrally formed, and the protrusion is located at the side close to the concave die and matched with the groove. One die stamps different positions of the torsional spring into the semi-arc parts with the same shape, position and size, the situation that the size and shape of the torsional arms are inconsistent with the size of those of a spring ring is avoided, and the torque precision is improved.

Owner:CHONGQING WANGJIANG IND

Device and method for testing torsional stiffness of radial section of piston ring

ActiveCN107677558BImproved Torque AccuracyEasy to fixMaterial strength using steady torsional forcesPiston ringClassical mechanics

The invention specifically provides a testing apparatus for testing the torsional rigidity of the radial section of a piston ring, belonging to the field of power machinery. The testing apparatus comprises the piston ring, a base, a pressing body, a force sensor, a loading handle, a leveling swing rod, a plumb, a displacement measuring swing rod, a first displacement sensor and a second displacement sensor, wherein a groove is arranged on the base, and a central column is arranged at the center of the groove on the base; the loading handle, the force sensor and the pressing body are sequentially arranged on the central column from top to bottom; the piston ring is arranged between the side surface of the pressing body and the inner wall of the groove on the base; the circumferential section of the piston ring is perpendicular to the central column; the top of the base is provided with a connecting rod which is provided with the leveling swing rod and the displacement measuring swing rod; the first displacement sensor is installed between the displacement measurement swing rod and the upper surface of the pressing body; and the second displacement sensor is installed between the side surface of the pressing body and the inner wall of the groove on the base. According to the invention, the radial section deformation of the piston ring is taken into consideration, so the precisionof torque determination of the piston ring is high, and accurate torsional rigidity of the radial section of the piston ring can be obtained.

Owner:HARBIN ENG UNIV

Speed reducing assembly

The invention relates to a speed reducing assembly which comprises a speed reducing mechanism, an input flange, a box body, an output flange, an input shaft, an output shaft and an output index plate. The speed reducing mechanism comprises at least a primary speed reducing unit, wherein the primary speed reducing unit comprises a primary sun friction wheel, a primary planetary friction wheel and a primary fine-adjustable clamping ring. The primary sun friction wheel is provided with an input shaft connecting sleeve, the input shaft is installed in the input shaft connecting sleeve, the input shaft connecting sleeve is installed in the input flange through a first rolling bearing, the periphery of the primary sun friction wheel is provided with at least three primary planetary friction wheels, the primary sun friction wheel is in driving connection with the primary planetary friction wheels and is in driving connection with the primary fine-adjustable clamping ring, the primary fine-adjustable clamping ring is fixedly connected with the box body, and the primary planetary friction wheels are in driving connection with the output index plate. The speed reducing assembly is simple in structure, the production efficiency is improved, and high output precision and low production cost can be ensured.

Owner:高克

A screw fastening system and method

ActiveCN112536754BImprove tightening effectReduce shock torqueElectric motor controlSpannersMotor speedElectric machine

The invention discloses a screw fastening system and method, which includes a speed setting unit, a torque setting unit, a filter unit, a speed torque control unit, a speed torque feedback unit, a current control unit, a speed weight unit, a torque weight unit, Motor, current detection unit, speed sensor, torque sensor, one end of the motor is connected to an electric wrench, the input end of the speed sensor, the input end of the torque sensor and the input end of the current detection unit are respectively connected to the motor, and the output end of the current detection unit is connected to the current control unit And provide the current feedback value to the current control unit; the speed torque control unit is connected with the current control unit, and the current control unit is connected with the motor. The present invention sets the speed torque control unit, the speed torque feedback unit and the current control unit to simultaneously control the construction torque of the screw to be fastened and the motor speed, reduce the impact torque, ensure higher torque accuracy, and effectively improve the tightening of the screw Effect.

Owner:GOOGOL PARADOX (DONGGUAN) INTELLIGENT TECH CO LTD

A controllable torque impact wrench torque online measurement method and device

ActiveCN113390543BSolve measurement problemsImprove the quality of twisting operationMeasurement of torque/twisting force while tighteningWork measurementWorking environmentImpact wrench

The invention relates to an on-line torque measurement method and device for a controllable torque impact wrench. According to the working environment of the torsion operation site and the elastic stage of the bolt work, the same batch of multiple sets of torsion thread pairs and workpieces are torsioned in the same process, and the accurate relationship between dynamic torque and rotation angle is measured and established and saved; during the measurement process , the online measuring device detects the accumulated rotation angle of the bolt / nut during the impact torque in real time, and substitutes the accumulated rotation angle into the relationship between the dynamic torque and the rotation angle to calculate and display the accumulated torque of the impact torque of the controllable torque impact wrench. The invention innovatively realizes the on-line measurement of the accumulated torque of the impact wrench, ensures the accuracy of torque control, and expands the scope of application of the impact wrench.

Owner:中国铁路郑州局集团有限公司科学技术研究所 +1

Torque transmission method and device

ActiveCN110094495BImprove securityImproved Torque AccuracyGearing controlTorque transmissionControl theory

The invention provides a torque transmission method and device. The torque transmission method includes the following steps: obtaining a torque compensation parameter corresponding to engine torque from a preset storage space, calculating according to the torque compensation parameter to obtain target torque, according to the target torque, controlling a target clutch, and transmitting the enginetorque. According to the torque transmission method, the torque compensation parameter corresponding to the torque of the engine is obtained from the preset storage space, calculation is performed according to the torque compensation parameter to obtain the target torque, and finally, according to the target torque, the target clutch is controlled, and the torque of the engine is transmitted, a control strategy of a dry double clutch transmission is avoided to apply to a wet double clutch transmission, the degree of accuracy of transmission of the engine torque of the wet double clutch transmission is improved, and the safety of driving of a vehicle is improved.

Owner:GREAT WALL MOTOR CO LTD

Magnetic levitation brake motor

InactiveUS20160268872A1Reduce errorsImproved Torque AccuracyPermanent-magnet clutches/brakesMechanical energy handlingMOSFETMagnetic reluctance

A magnetic levitation brake motor, which is very applicable to automatic screwdrivers. A motor providing power output is combined with a magnetic levitation clutch, the alternating effect of homopolar repulsion and heteropolar attraction in the operation of the magnetic levitation clutch can reduce the motor starting current, and the motor has less inertia moment and friction force, reducing the heating and damage of MOSFET controlling drive motor current. In the operation, the magnetic levitation clutch runs when the motor is started, and the inertia moment is increased and the kinetic energy is accumulated. Under a load, the rotation speed of the magnetic levitation clutch decreases and kinetic energy is released to increase the torque. The motor stops when the preset torque is reached. The magnetic levitation clutch keeps running due to inertia moment, but it stops gradually due to the reluctance generated by pole effect.

Owner:HSU HSIU LIN

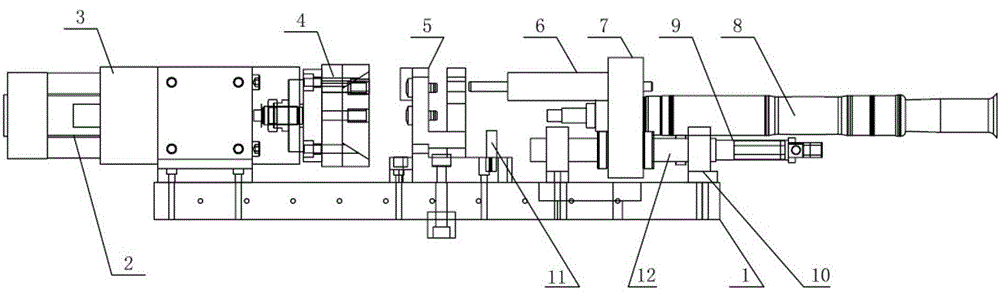

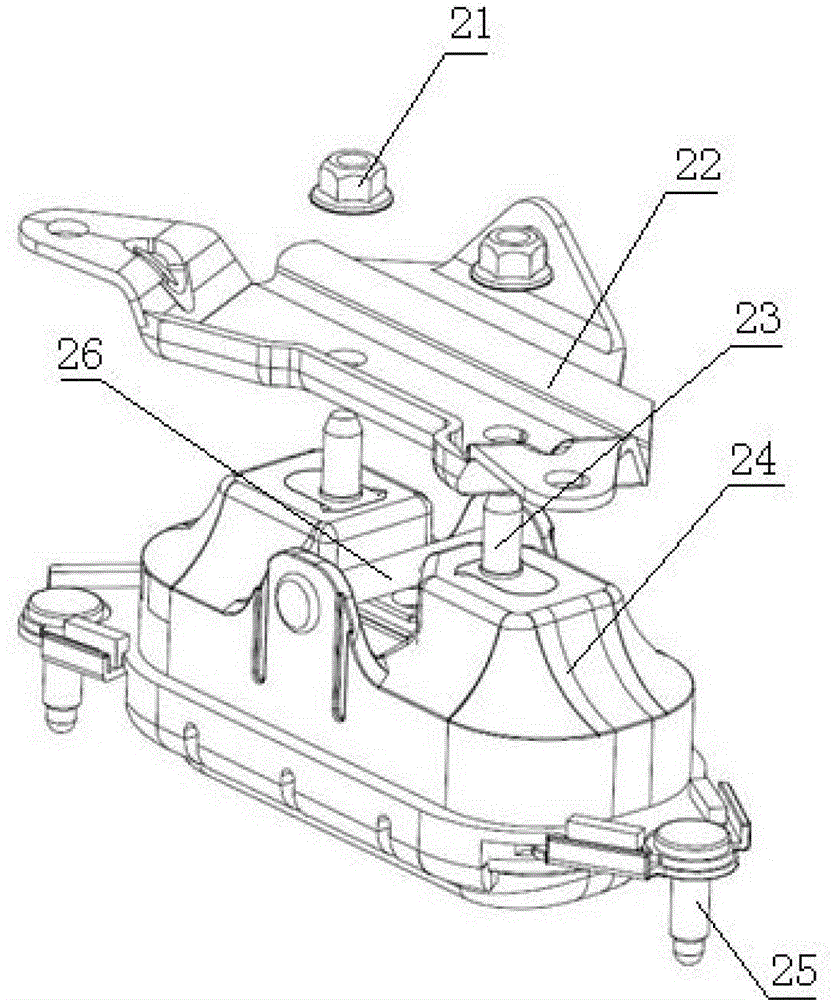

Revolving-riveting assembling tooling for automobile hydraulic mount pieces and application method of revolving-riveting assembling tooling

Owner:NINGBO TUOPU GROUP CO LTD

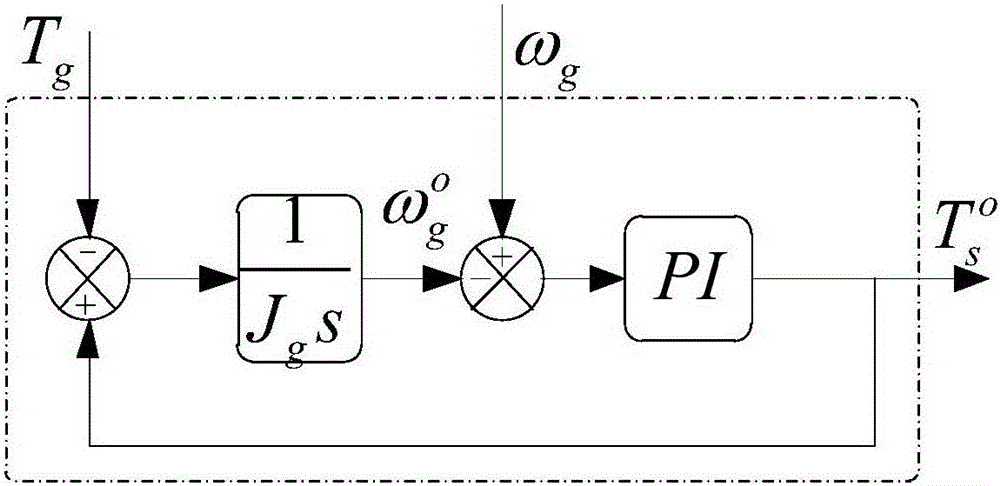

Obtaining method for transmission chain high-speed shaft torque of double-fed wind turbine generator

InactiveCN105162378AImprove reliabilityImproved Torque AccuracyGenerator control by field variationElectricityGrid fault

The invention provides an obtaining method for transmission chain high-speed shaft torque of a double-fed wind turbine generator, comprising the following steps: obtaining electromagnetic torque of the double-fed wind turbine generator; and obtaining the high-speed shaft torque of the double-fed wind turbine generator. According to the obtaining method for transmission chain high-speed shaft torque of the double-fed wind turbine generator, a torque measurement device is not required additionally, so that the obtaining method is rapid in convergence, accurate in calculation, high in reliability, suitable for obtaining torque under grid faults without depending on complete mathematical models in conventional systems, and higher in adaptive ability.

Owner:CHINA ELECTRIC POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com