Testing apparatus and method for testing torsional rigidity of radial section of piston ring

A technology of torsional rigidity and radial cross-section, applied in the field of piston rings, can solve the problems of complex calculation of piston rings, difficulty in accurate measurement of piston ring torque, and disregard of torsional motion of piston rings, etc., to achieve high test efficiency, improve the fixing effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

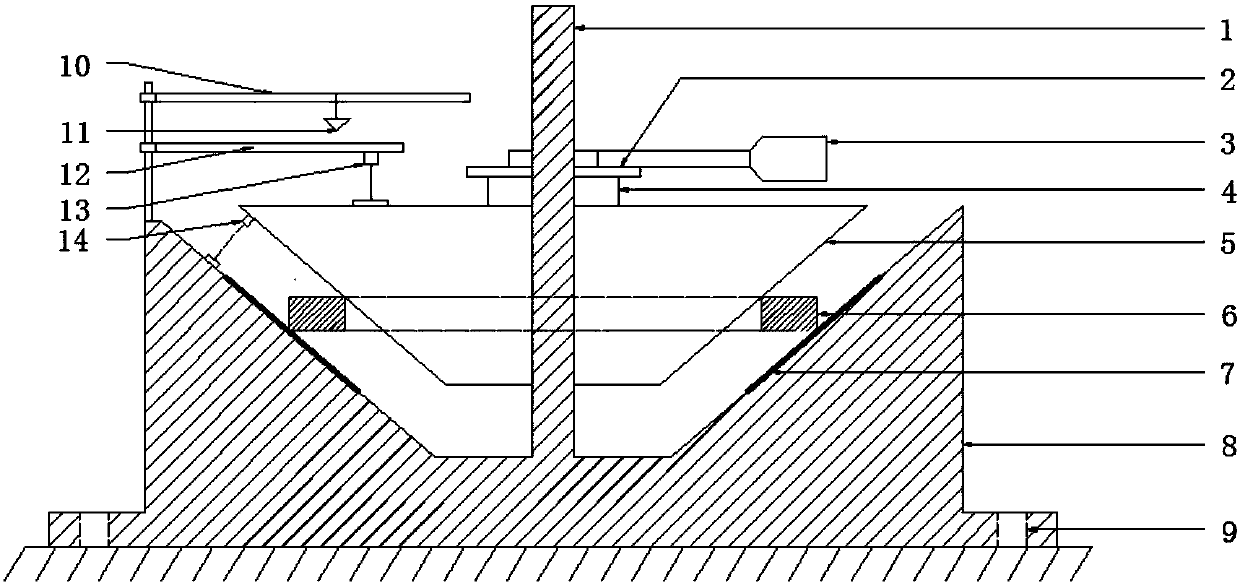

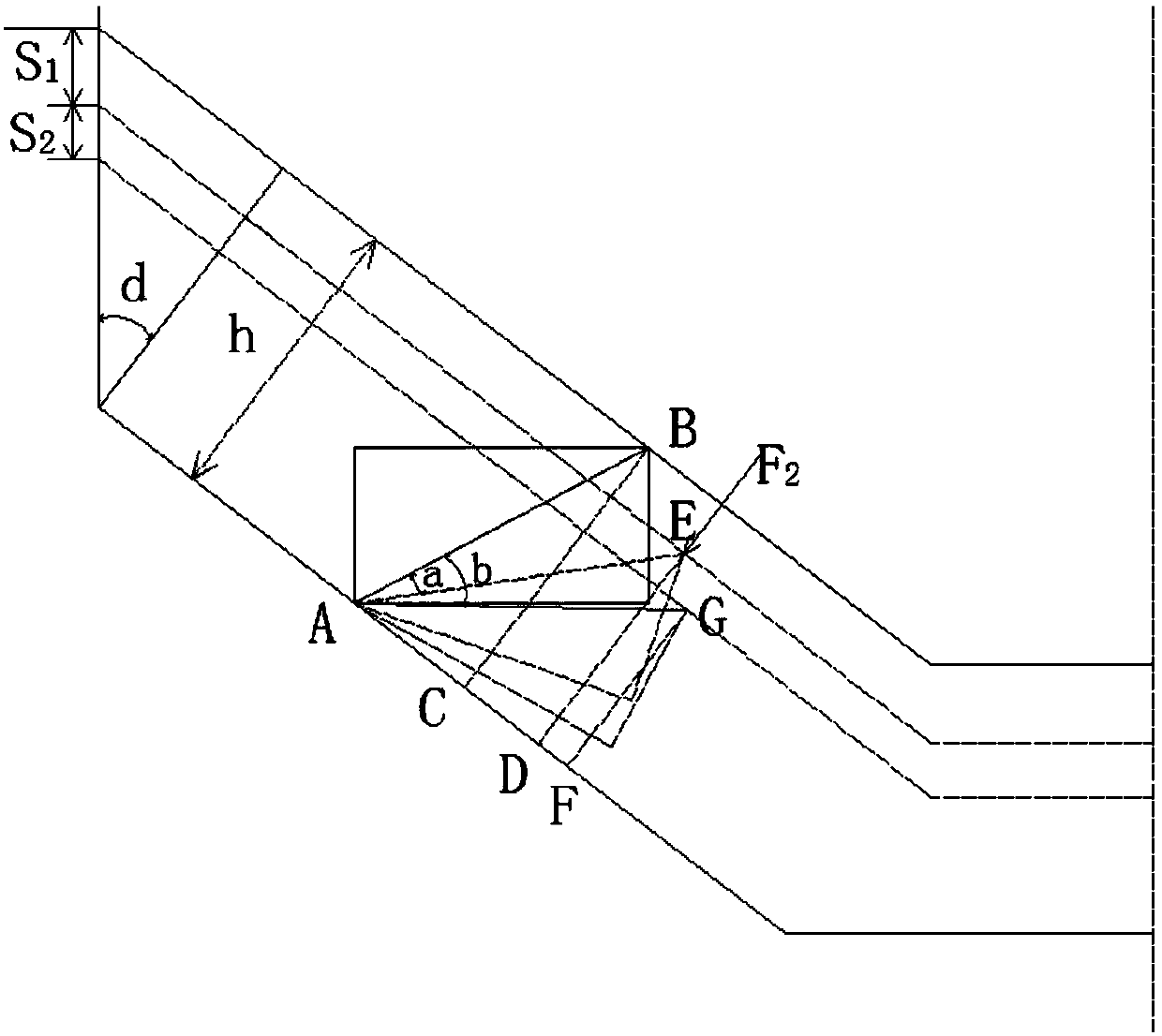

[0037] Combine below Figure 1 ~ Figure 2 This device will be specifically described. The utility model relates to a test device for torsional rigidity of a radial section of a piston ring.

[0038] The purpose of the present invention is achieved in this way, including: piston ring 6, base 8, pressure body 5, force sensor 4, loading handle 3, leveling pendulum 10, plumb 11, displacement measurement pendulum 12, first displacement Sensor 13 and second displacement sensor 14;

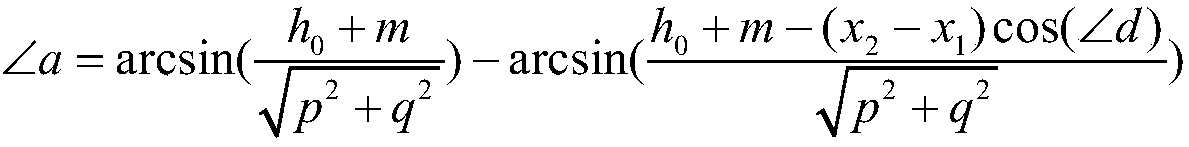

[0039] There is a groove on the base 8, and the inner wall of the groove of the base is a circumferentially symmetrical slope. There is a central column 1 in the center of the groove of the base, and the central column 1 is fixedly connected with the base 8; the central column 2 is sequentially arranged from top to bottom. A loading handle 3, a force sensor 4 and a pressure body 5 are installed; the side of the pressure body 5 is a circumferentially symmetrical slope; the piston ring 6 is installed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com