Revolving-riveting assembling tooling for automobile hydraulic mount pieces and application method of revolving-riveting assembling tooling

A technology for hydraulic mounting and assembling tooling, which is applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of high operating load of employees, low work efficiency, and difficulty in nut torque accuracy requirements, so as to reduce investment and operation. Convenience and reliable product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

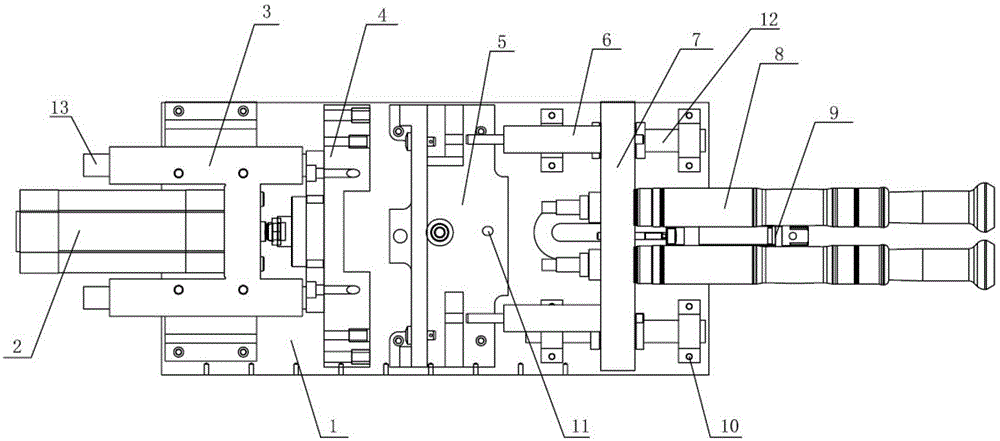

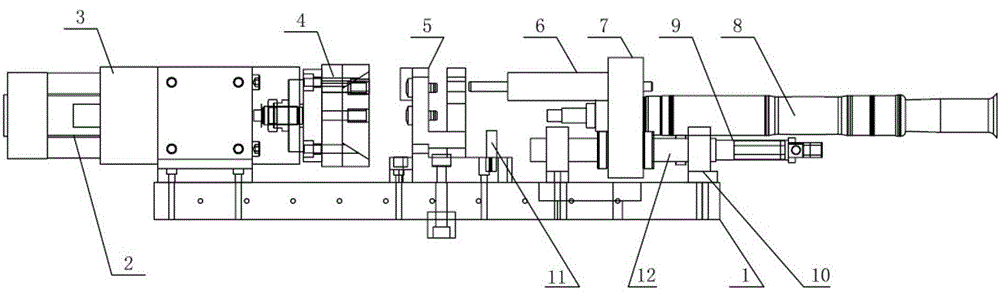

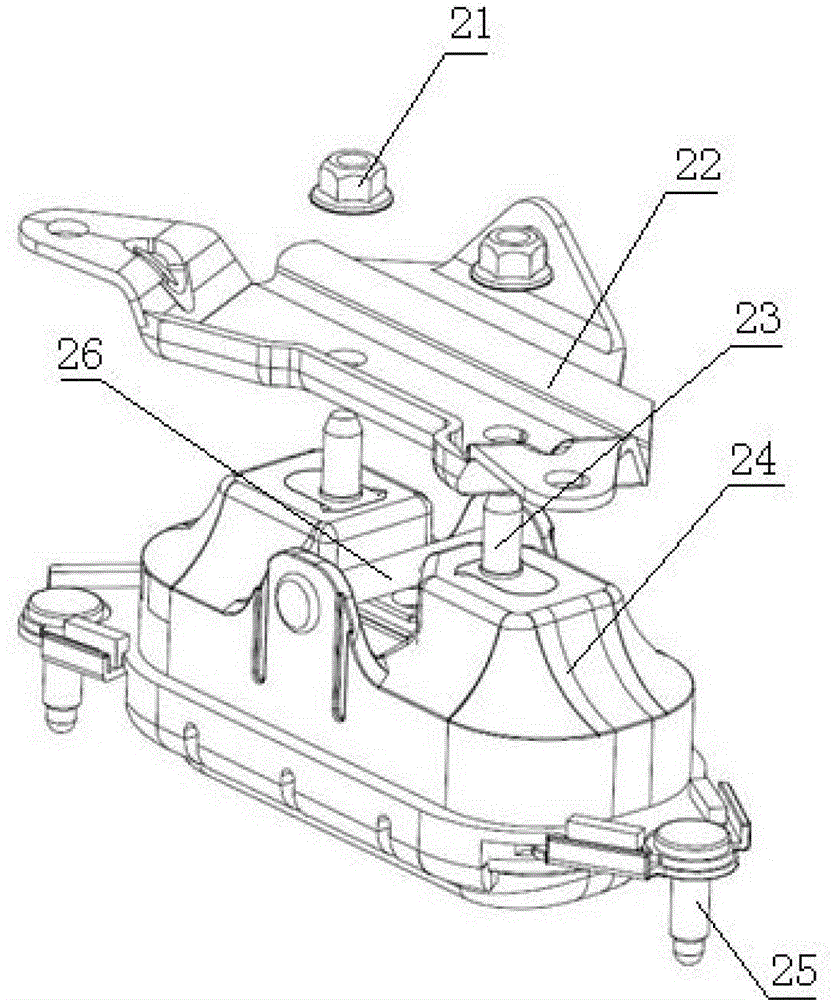

[0031] It is necessary to process an automobile hydraulic mount. The specific processing steps are as follows:

[0032] (a) Place the tooling device on the workbench of a vertical riveting machine, first manually pass the bumper 26 into the two mounting holes in the middle of the upper end of the main spring 24, and then place the workpiece horizontally on the workpiece support frame 5, the bottom of the main spring 24 of the workpiece faces the clamping head 4, and at the same time, the ejector pin 52 withstands the bottom plate screw 25 of the workpiece;

[0033] (b) An iron sheet 22 is placed on the front end of the main spring 24 and passed on the mounting screw 23 on the upper end of the main spring 24, and the middle hole 27 at the front end of the iron sheet 22 is pierced with a hole detection pin 11 for positioning;

[0034] (c) Adsorb the two mounting nuts 21 on the front end of the digital display electric torque gun 8, start the guide clamping cylinder 2 to push the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com