Obtaining method for transmission chain high-speed shaft torque of double-fed wind turbine generator

A double-fed wind turbine, high-speed shaft torque technology, applied in the direction of controlling generators through magnetic field changes, can solve the problems of increasing measurement errors, reducing reliability, and large sensor linear velocity, and achieving improved torque accuracy, high reliability, and high reliability. Calculate the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

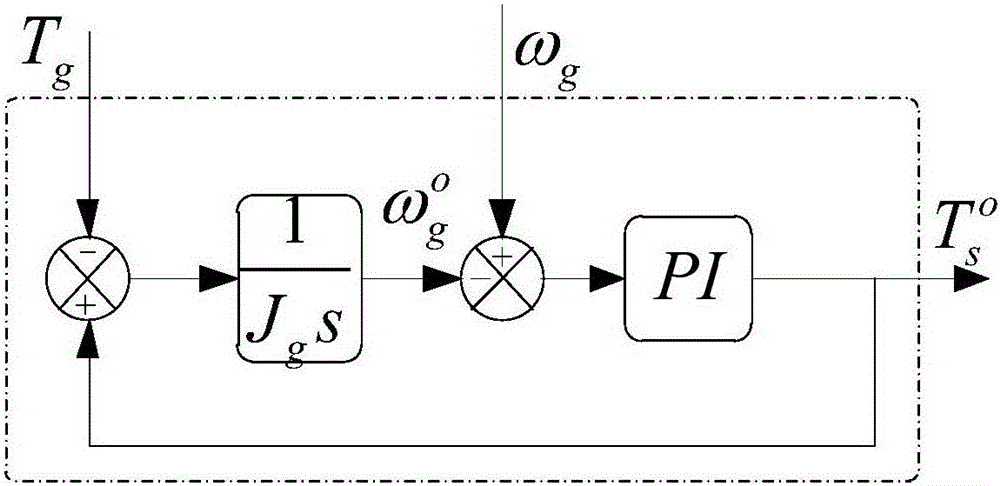

[0039] The invention provides a method for obtaining high-speed shaft torque of a doubly-fed wind turbine transmission chain, the method comprising the following steps:

[0040] Step 1: Obtain the electromagnetic torque of the doubly-fed wind turbine;

[0041] Step 2: Obtain the high-speed shaft torque of the doubly-fed wind turbine.

[0042] Described step 1 comprises the following steps:

[0043] Step 1-1: Obtain the three-phase stator voltage and three-phase stator current of the doubly-fed wind turbine and the actual speed of the doubly-fed wind turbine;

[0044] Step 1-2: Perform signal conditioning and AD conversion on the obtained three-phase stator voltage and three-phase stator current of the doubly-fed wind turbine;

[0045] Step 1-3: Calculate the electromagnetic torque of the DFIG.

[0046] In the step 1-1, the three-phase stator voltage and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com