Detecting trolley of hydraulic torque wrench

A technology of torque wrench and detection trolley, which is applied to measure the direction of torque/torsion force when tightening, which can solve the problems of inconvenience and affecting the normal use of the production site, and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

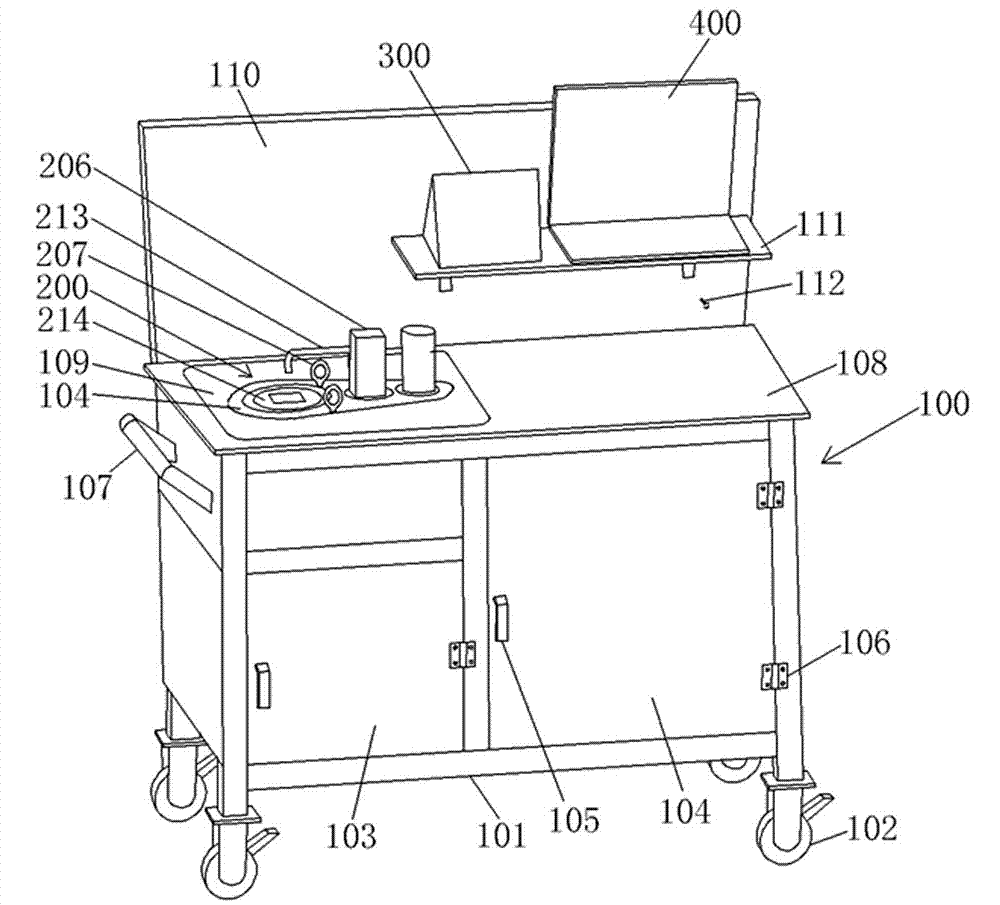

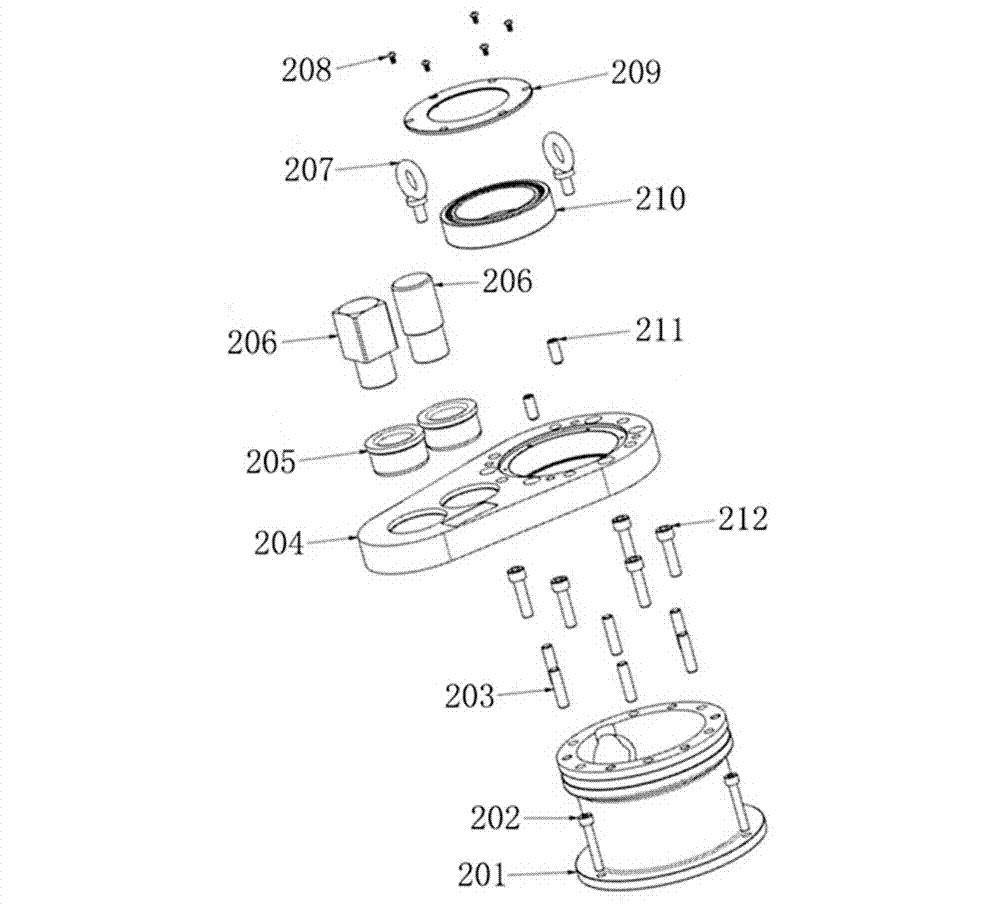

[0022] Such as figure 1 , figure 2 As shown, a detection cart of a hydraulic torque wrench includes a tool cart 100 and a torque detection mechanism 200 arranged on the tool cart 100. The torque detection mechanism 200 includes a base 201, a static torque sensor 214, a fixed plate 204, and a needle bearing 210. And the reaction force column 206, the base 201 is connected with the tool cart 100 by the flange and the base fixing bolt 202, the base 201 is provided with a mounting groove corresponding to the shape of the static torque sensor 214, the static torque sensor 214 is arranged in the mounting groove, the base 201 A connection square hole is provided at the lower end of the installation groove, and the output shaft at the bottom of the static torque sensor 214 is inserted into the connection square hole. The upper end surface of the base 201 is uniformly provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com