Speed reducing assembly

A technology of assembly and reduction mechanism, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large backlash, low precision and efficiency, large backlash, etc., to achieve no backlash, output The effect of high torque accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

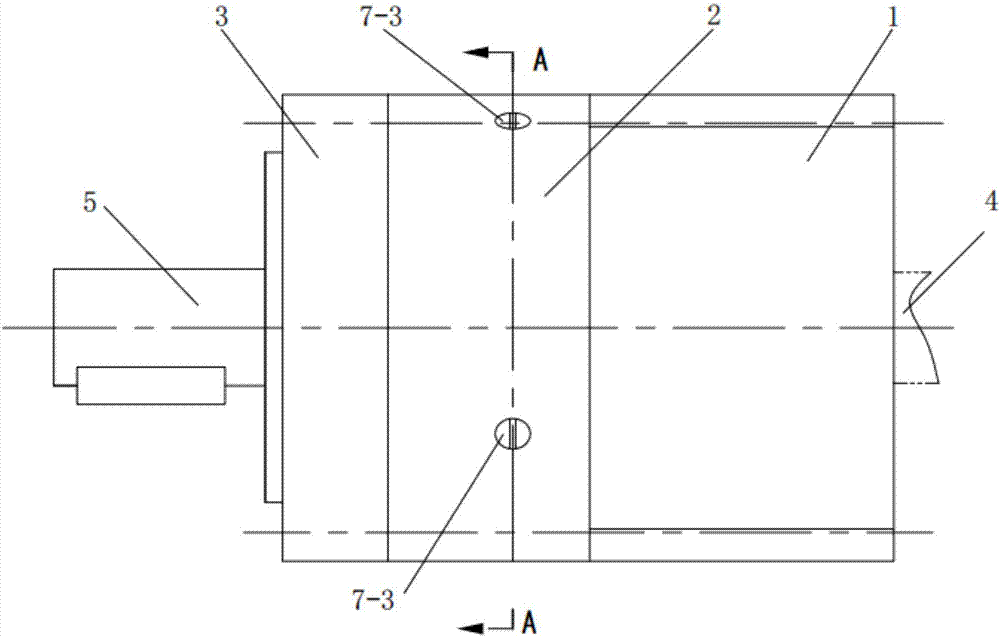

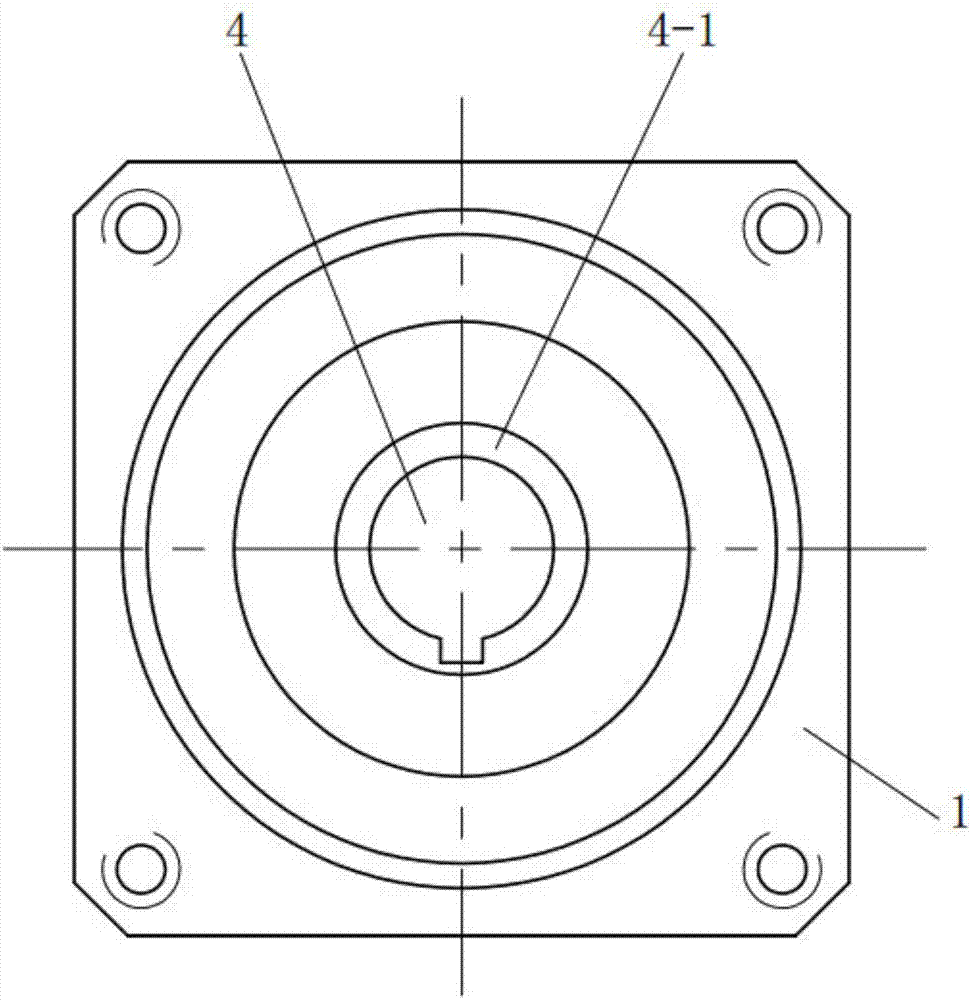

[0038] Such as figure 1 , 2 , 3, 4, 5, and 10, a deceleration assembly, including a deceleration mechanism, an input flange 1, a box body 2, an output flange 3, an input shaft 4, an output shaft 5 and an output indexing plate 5-1 ;

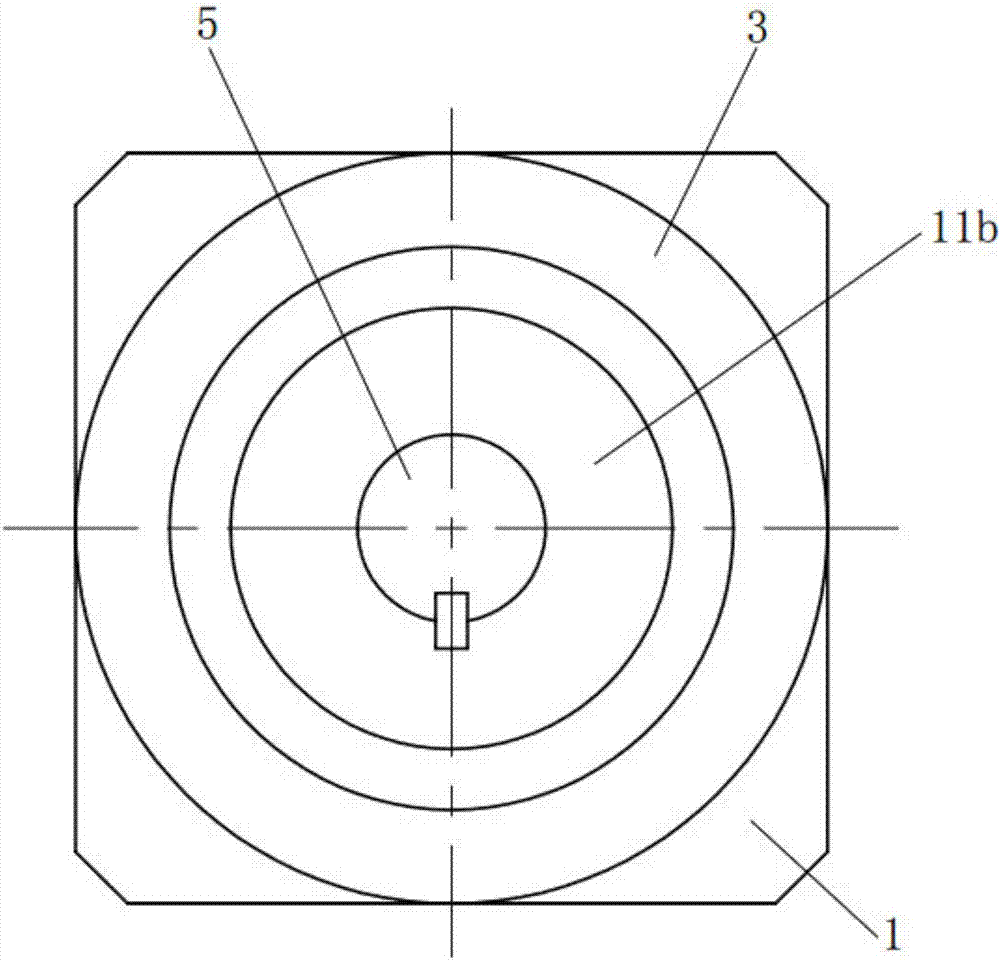

[0039] The input flange 1, the box body 2 and the output flange 3 are connected as a whole by fasteners, and the box body 2 is located between the input flange 1 and the output flange 3, and the output shaft 5 passes through the second rolling bearing 9b Put it into the output flange 3, and the output shaft 5 and the output index plate 5-1 are integrated or fixedly connected with each other, and the speed reduction mechanism is set in the box body 2;

[0040] The reduction mechanism at least includes a first-stage reduction unit, and the first-stage reduction unit includes a first-stage sun friction wheel 8a, a first-stage planetary friction wheel 6a, and a first-stage fine-tunable clamping ring 7a;

[0041] The first-stage sun friction wheel 8...

Embodiment 2

[0053] Such as Figure 6 , 7 , 8, 9, and 10, the difference between embodiment 2 and embodiment 1 is that the reduction mechanism in embodiment 2 also includes a two-stage deceleration unit, and the two-stage deceleration unit includes a two-stage sun friction wheel 8b , two-stage planetary friction wheel 6b and two-stage fine-tuning clamping ring 7b;

[0054] The outer circumference of the secondary sun friction wheel 8b has at least three secondary planetary friction wheels 6b, the secondary sun friction wheel 8b is frictionally connected to the secondary planetary friction wheel 6b, and the secondary planetary friction wheel 6b is connected to the secondary planetary friction wheel 6b The fine-adjustable clamping ring 7b is frictionally connected, and the secondary fine-adjustable clamping ring 7b is fixedly connected to the box body 2;

[0055] The secondary sun friction wheel 8b is in transmission connection with the primary planetary friction wheel 6a, and the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com