Torque on-line measurement method and device for torque-controllable impact wrench

A technology of impact wrench and measuring method, applied in measuring device, force/torque/work measuring instrument, measuring torque/torsion force during tightening, etc., which can solve the problem that the output torque value of impact wrench cannot be given, and the output of impact wrench cannot be accumulated. Issues such as torque detection and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

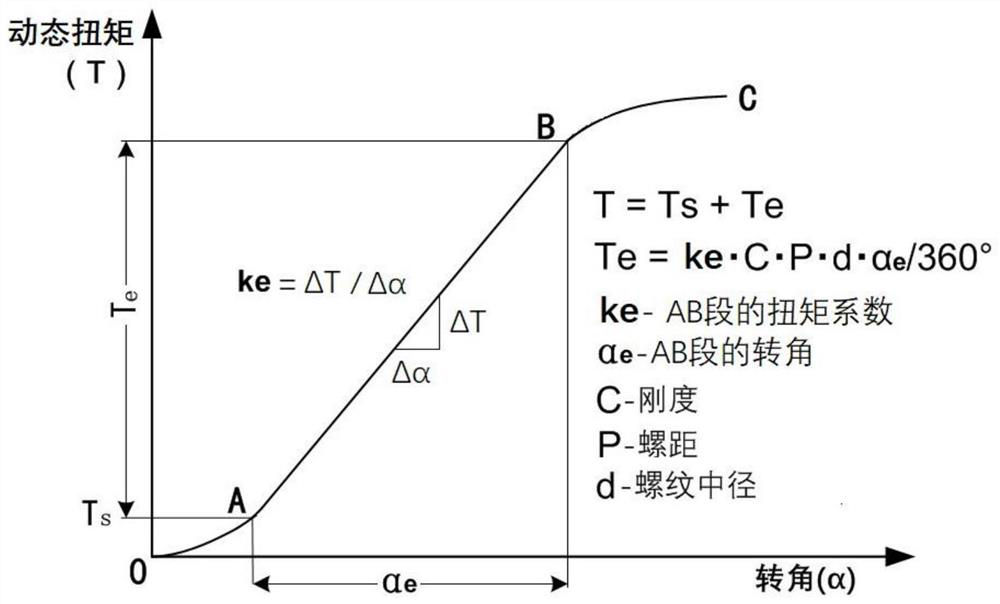

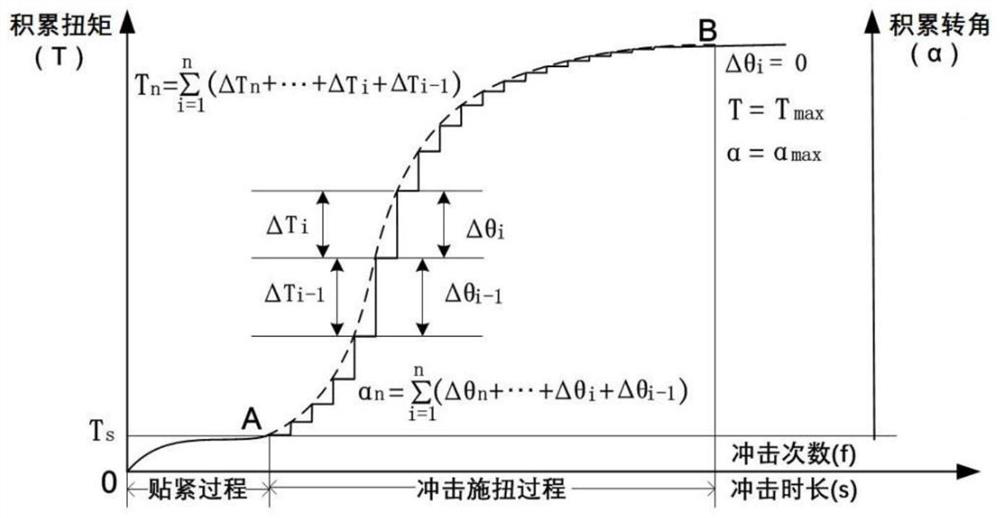

[0046] see figure 1 , image 3 and Figure 4 , the online measurement method of the controllable torque impact wrench of the present invention, the steps of measuring the torque of the controllable torque impact wrench at the job site are as follows (in order to ensure the measurement accuracy, the measured torque is dynamic torque):

[0047] S1, according to the relationship between torque and rotation angle in the tight stage (O-A section), elastic stage (A-B section), and superelastic stage (B-C section) during the thread pair torsion process, measure the dynamic torque and rotation angle in real time, and save the dynamic torque and rotation angle curve coordinate data;

[0048] S2, use the coordinate data of the dynamic torque and rotation angle curve to continuously calculate the k value (ΔT / Δα), substitute the k value into the mathematical model of the intersection of the calculation curve and the straight line established through the test, and calculate and determine...

Embodiment 2

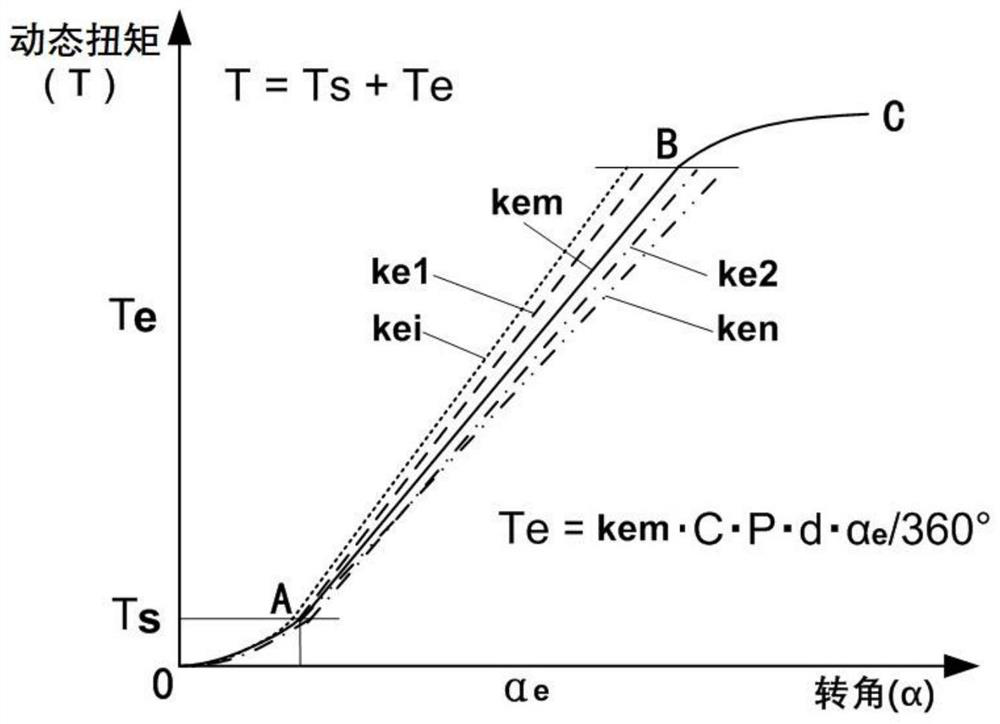

[0060] When twisting in the elastic stage, the torque coefficient ke is related to the frictional surface roughness, lubrication condition, surface coating, material hardness, thread pair tolerance, machining accuracy (cylindricity, straightness, tooth shape error, Pitch error, etc.), assembly cleanliness, even if the same batch of torsion workpieces, bolts / nuts and washers and the same torsion process are used, the ke value also has a certain dispersion (such as figure 2 Shown), reducing the dispersion is beneficial to improve the torque control accuracy;

[0061]The controllable torque impact wrench torque online measurement method of this embodiment adopts the following method to reduce the dispersion: for the same batch of workpieces, bolts / nuts and washers and using the same torsion process, multiple sets of thread pairs are respectively torsion, and the dynamic measurement is performed in real time. The data of the coordinate points of the torque and rotation angle curv...

Embodiment 3

[0065] see Figure 7 , Figure 8 , Figure 9 and Figure 10 , this embodiment is an on-line measurement device for implementing the above-mentioned on-line measurement method for the controllable torque impact wrench torque.

[0066] The on-line measurement device of the torque of the controllable torque impact wrench, the device body 10 includes a drive square hole 11, an output square tenon 13 and an elastic body 14 connecting the drive square hole and the output square tenon. There is a torque sensor 18, a rotation angle sensor and a microelectronic detection and processing unit 20, and the microelectronic detection and processing unit 20 includes a microcontroller 21, a torque signal conditioning circuit 22, a rotation angle signal conditioning circuit 23 and an OLED display 25; The controller 21 includes a data processing unit and a non-volatile memory; the non-volatile memory stores the algorithm program of the online measurement method of the controllable torque impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com