Device and method for controlling oil pressure of vehicle

A technology for oil pressure control and vehicle, which is applied to control devices, vehicle components, transmission control, etc., can solve the problems of inability to obtain accuracy, and achieve the effect of simple structure and improved torque accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

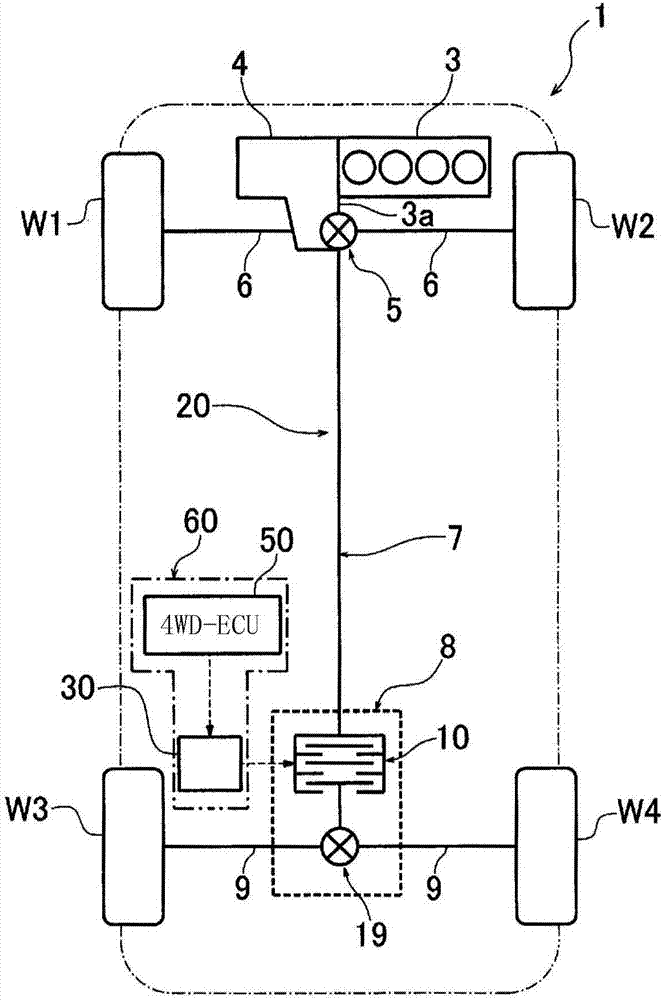

[0016] figure 1 It is a diagram showing a schematic configuration of a four-wheel drive vehicle equipped with a hydraulic control device according to an embodiment of the present invention. The four-wheel drive vehicle 1 shown in the figure has: an engine (drive source) 3 mounted horizontally on the front of the vehicle; an automatic transmission 4 integrally provided with the engine 3; and a front wheel for transferring power from the engine 3 The driving force transmission path 20 through W1, W2 and rear wheels W3, W4.

[0017] The output shaft (not shown) of the engine 3 passes through the automatic transmission 4, the front differential (hereinafter referred to as the "front differential") 5, the left and right front drive shafts 6, 6, and the main drive wheels, namely the left and right front wheels. W1 and W2 are connected. In addition, the output shaft of the engine 3 passes through the automatic transmission 4, the front differential 5, the transmission shaft 7, the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com