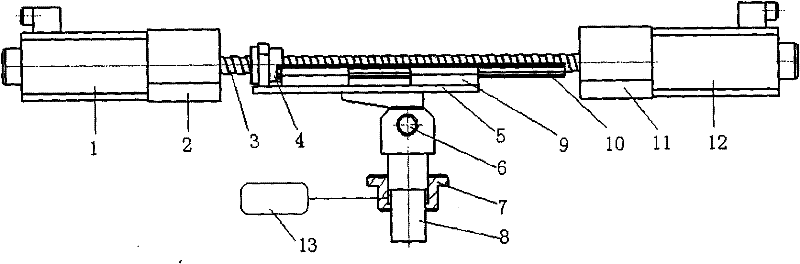

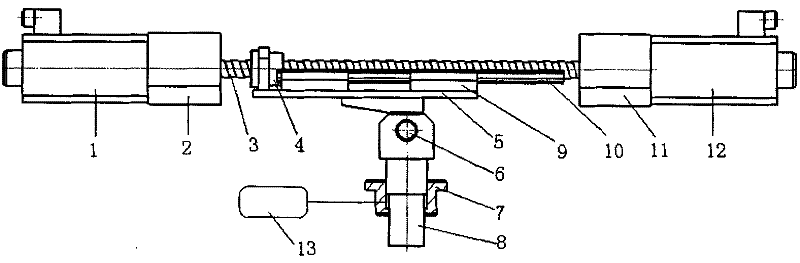

Main transmission mechanism of servo numerical control rotary head press

A press and main drive technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve problems such as large impact noise, reduce side load, ensure accuracy, and reduce difficulty in selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The utility model relates to a main transmission mechanism of a servo numerical control rotary head press, which is used for a stamping head of the servo numerical control rotary head press. The main transmission system of the servo drive consists of two medium-torque and small-inertia motors (1) 1, (2) 12 through the safety coupling with pulse unloading function installed in the support (1) 2, (2) 11 and precision The large-lead ball screw 3 is connected, the driving mechanism of the small-angle rolling wedge 5, the screw nut 4 and the ball guide slider 9 are fixed together, and the ball guide 10 is fixed to the frame; the wedge 5 drives the roller 6, the stamping head 8 Up and down movement; two medium-torque and small-inertia motors (1) 1, (2) 12 and multi-motor synchronous drive and precise control can meet the requirements of heavy load and high dynamic response performance of the system at the same time. The wedge 5 is supported by a ball rail runner 9 and a ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com