Engine start device of a rotary valve carburetor

一种发动机起动、化油器的技术,应用在机器/发动机、化油器、发动机元件等方向,能够解决妨碍化油器紧凑型、扩大化油器尺寸等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

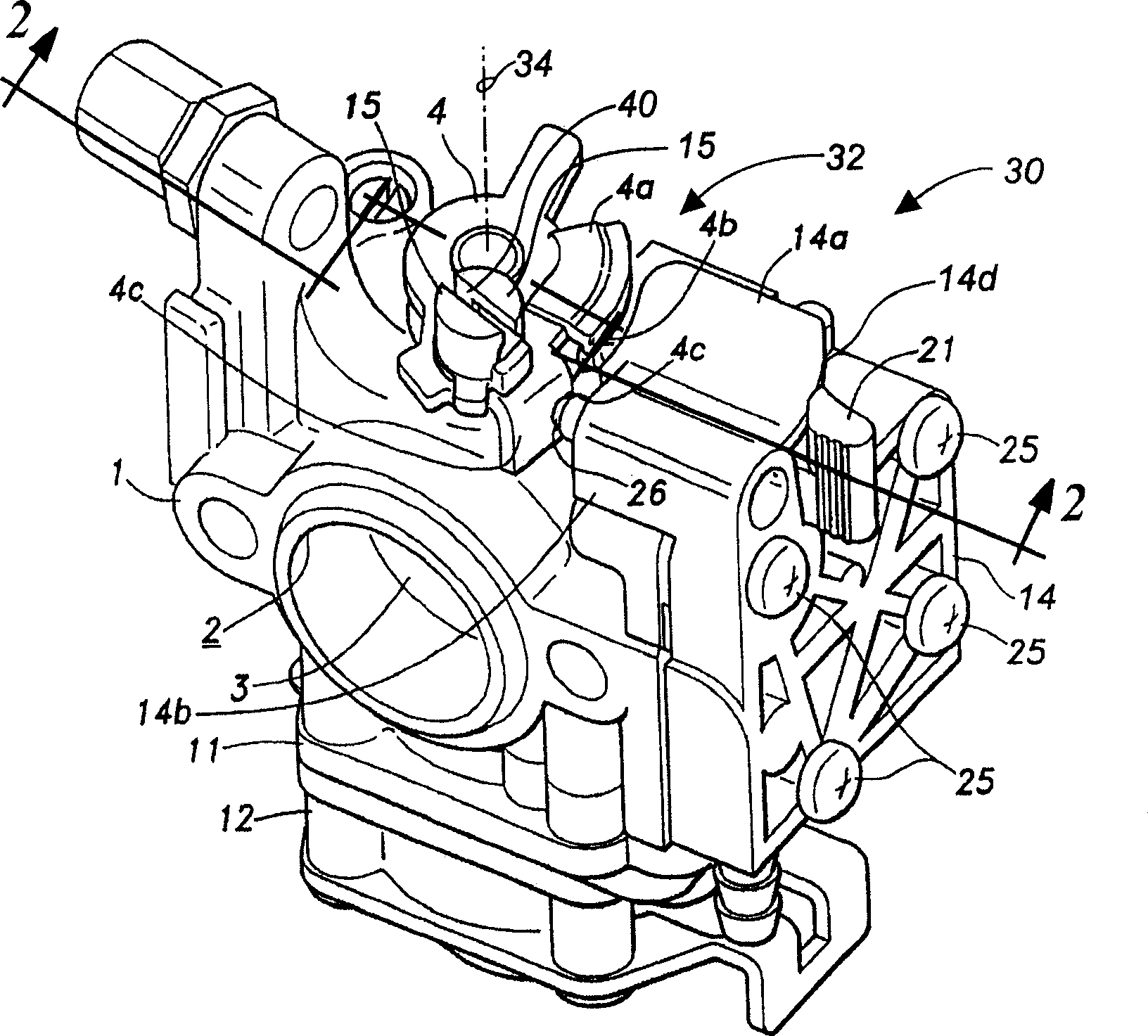

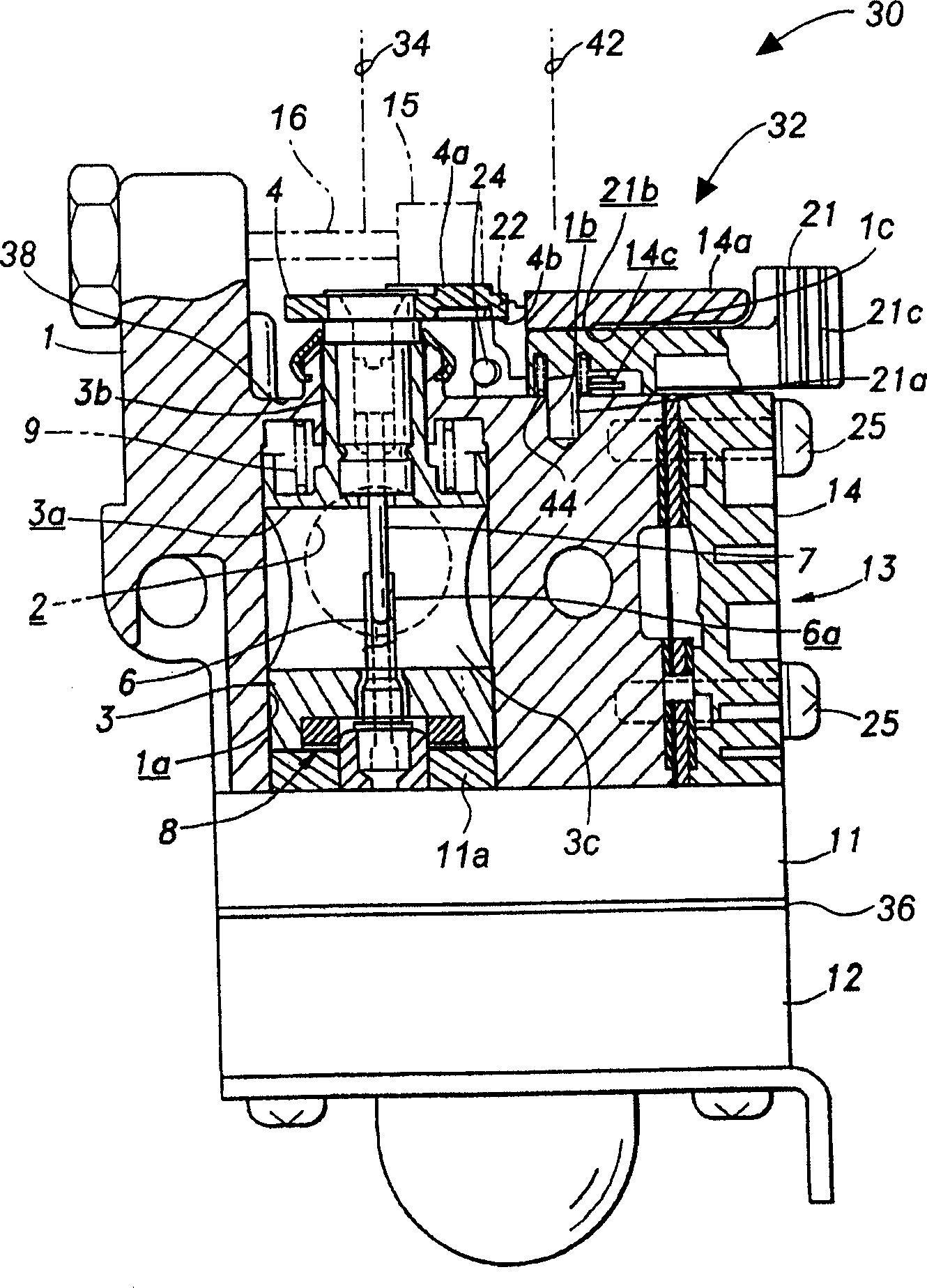

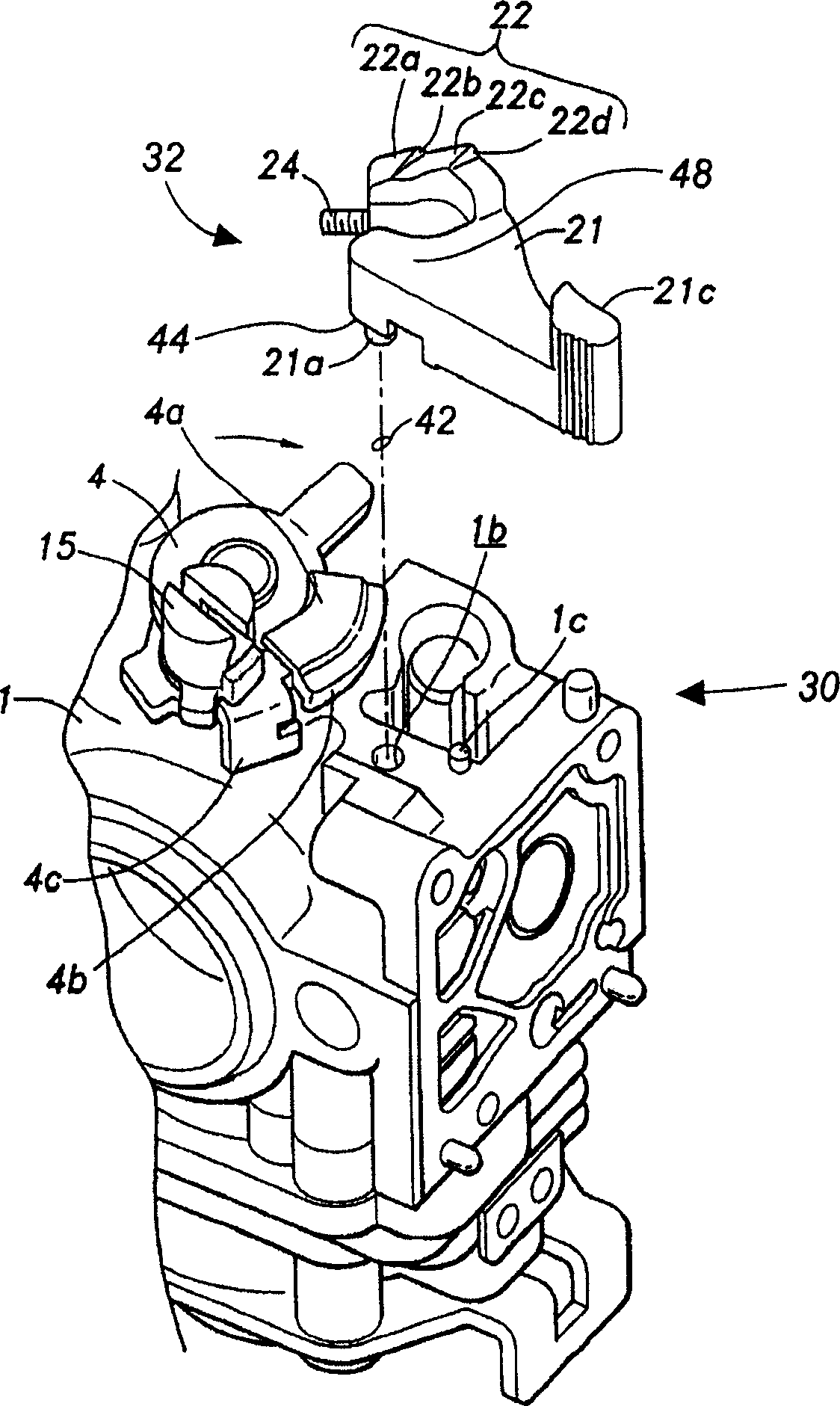

[0024] Best as figure 1 with 2 As shown, the rotary valve carburetor 30 equipped with the starter engine device 32 of the present invention has a fuel-air mixing passage 2 extending through the main body 1. The main body 1 has a substantially cylindrical cavity 1 a that extends laterally across the mixing channel 2 so that the rotary throttle valve 3 is usually rotatably and axially movably mounted. The rotary throttle valve 3 has: a cylindrical portion 3c, which rotates around a rotation axis 34 and moves axially with respect to the rotation axis 34, the rotation axis 34 is arranged to be substantially perpendicular to the mixing passage 2; and a through hole 3a, It is generally oriented perpendicular to the axis of rotation 34 and extends laterally through the cylindrical portion 3c. The through hole 3a is oriented so that the degree or size of the communication with the fuel-air mixing passage 2 is changed between a fully closed state and a fully opened state. Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com