Device for automatically injecting liquids to be injected

An automatic injection and injection technology, applied in the direction of automatic injectors, syringes, ampoule syringes, etc., can solve problems such as hindering the rapid introduction of injections, not fully meeting actual requirements, blocking injection needles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

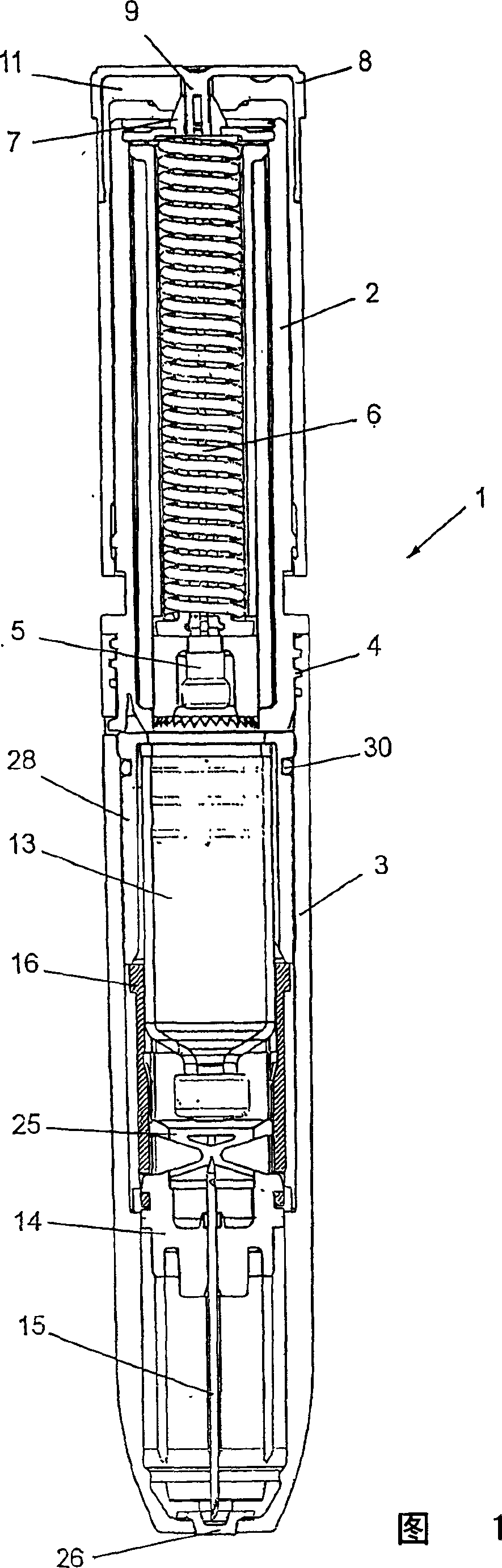

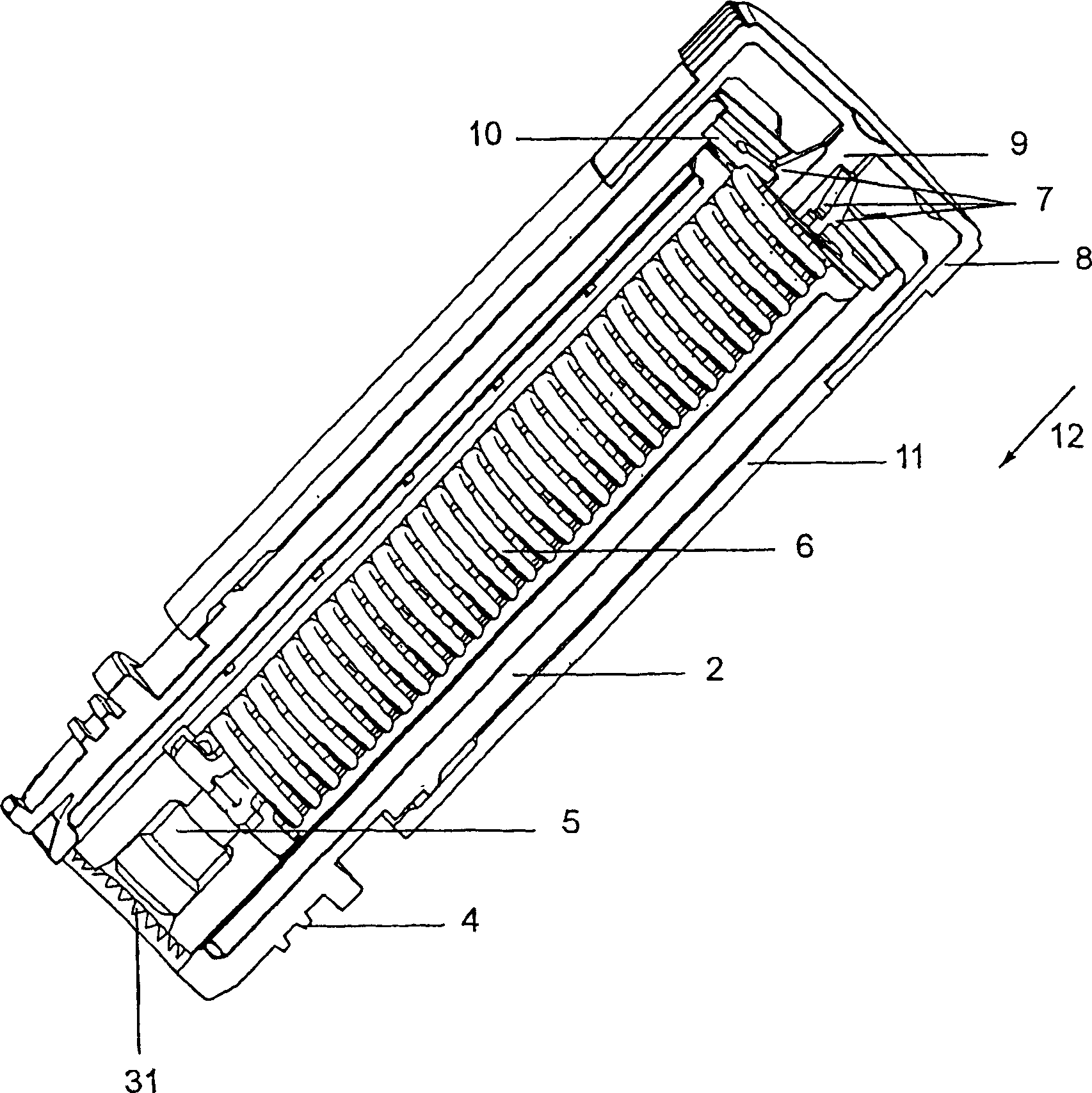

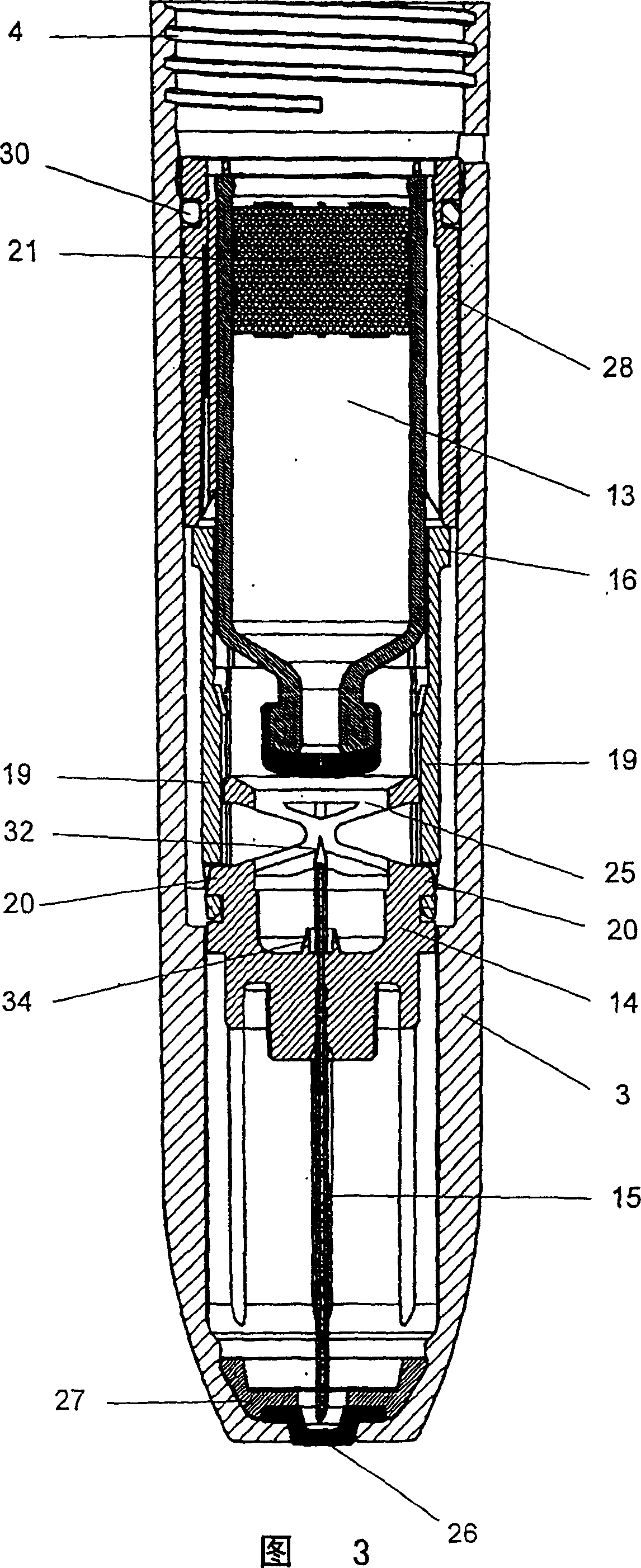

[0014] FIG. 1 shows an injection device 1 , the housing of which is segmented in the axial direction. The first housing part 2 encloses the actuator part and the second housing part 3 encloses the syringe part of the injection device according to the invention, wherein the two housing parts can be connected by means of a screw thread 4 . exist figure 2 The actuator part shown in detail in includes a pressure bolt 5 which is axially displaceable in the housing 2 and which can be pushed in against a spring 6 . The pressure screw 5 has an inwardly elastic locking shoulder 7 which forms the conical end of the pressure screw 5 . In the locked position, a pin 9 of the cover 8 holds the locking shoulder 7 in a radially outwardly offset position, so that the locking shoulder 7 engages the ring part 10 . After the top cover 8 has been pulled off, the actuator can be partially released. For this reason, the protective sleeve 11 is operated in the direction of the arrow 12, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com