a transformer

A technology for transformers and power frequency withstand voltage, applied in the field of transformers, can solve the problems of current driving capacity limitation, inability to achieve insulation withstand voltage, and unstable power supply magnetic flux saturation, so as to increase current driving capacity, ensure starting capacity, and prevent trending. skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

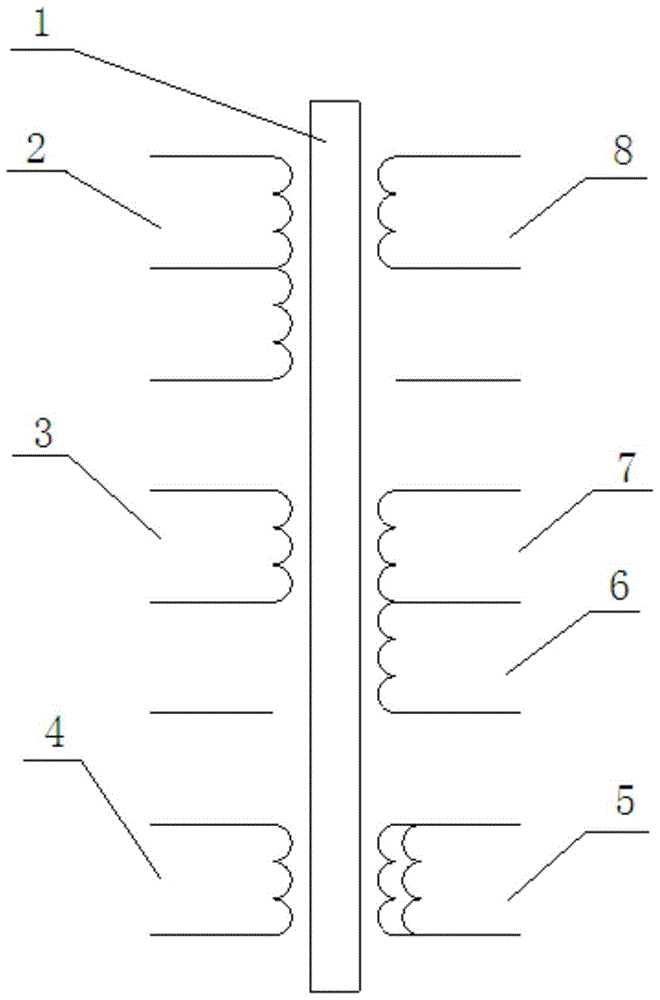

[0010] figure 1 As shown, it is a transformer, including an iron core 1 and a coil winding arranged on the iron core 1, and the coil winding includes a primary winding 2 and a secondary winding; the primary winding 2 is provided with 76 turns of the main Copper wire, the diameter of the main copper wire is 27AWG; the secondary winding includes a first feedback winding 3 with 6 turns of the first copper wire, a second feedback winding 4 with 16 turns of the second copper wire, and The third feedback winding 5 with 4 double-turn third copper wires, the fourth feedback winding 6 with 8 turns of the fourth copper wire, the fifth feedback winding 7 with 8 turns of the fifth copper wire, and 16 turns The sixth feedback winding 8 of the sixth copper wire. Wherein, the diameter of the first copper wire is 29AWG, and the diameters of the second copper wire, the third copper wire, the fourth copper wire, the fifth copper wire and the sixth copper wire are 25AWG. In addition, the power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com